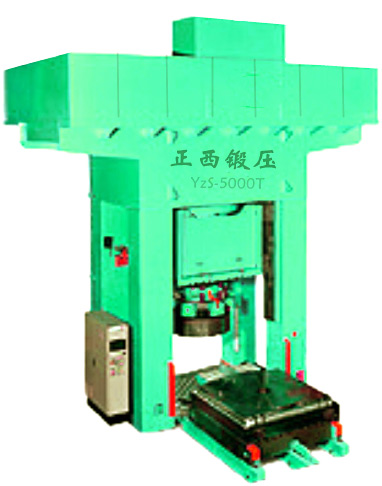

china hot forging factory – Hot Forging Hydraulic Press – Zhengxi

china hot forging factory – Hot Forging Hydraulic Press – Zhengxi Detail:

Yz14 Fast Free Forging Hydraulic Press

Frame type and four-column structure;

Using servo control system, high energy saving;

Fast 400~1000mm/S, forming 50~200mm/S;

The body is welded with Q355B material, with strong overall rigidity;

Equipped with upper bolt and double support safety protection device;

Optional auxiliary centering device, auxiliary punching device, precision automatic forging, manipulator and other configurations;

Free forging, suitable for large forgings with simple appearance, for forging various large shafts, rings, cakes, ingots and plates;

Suitable for forging of various carbon steel, alloy steel, tool steel, bearing steel, spring steel, stainless steel and high temperature alloy steel;

Used in aerospace, power, industry, shipbuilding, transportation and other fields;

Precision Die Forging Hydraulic Press

Frame type and four-column structure, which can be used for hot forging or cold extrusion.

Servo control system, micro-movement molding, pressure and position control accuracy 1% ;

Adjustable speed 1~100mm/S, stepless speed change, high forming accuracy;

The body is welded with Q355B material, with strong overall rigidity;

Equipped with upper and lower ejection cylinders, the ejection cylinder has a built-in sensor to precisely control the ejection molding;

Widely used in automobile, machinery, petrochemical, boiler manufacturing, aerospace, shipbuilding and other industries.

The one-time molding of polyhedral structural parts can significantly increase the strength of parts, reduce production costs, and promote lighter parts.

Hot Die Forging Hydraulic Press

The main feature of hot die forging is the control of the temperature deviation between the mold and the formed part. The mold temperature can be set to be higher than the material temperature, isothermal, and low temperature.The deformed material often undergoes dynamic recrystallization during the forging process, which makes the forging The structure is uniform and equiaxed fine crystal morphology;

Pressure control accuracy ±0.1Mpa, position control accuracy ±0.02mm 。

The forming speed is fast, the formed parts have high dimensional accuracy and low cost..

Optional electric heating, intermediate frequency, high frequency and other heating methods, automatic loading and unloading, moving out of the workbench;

Widely used in transportation, vehicles, aerospace, shipbuilding, infrastructure, 3C electronics and other fields

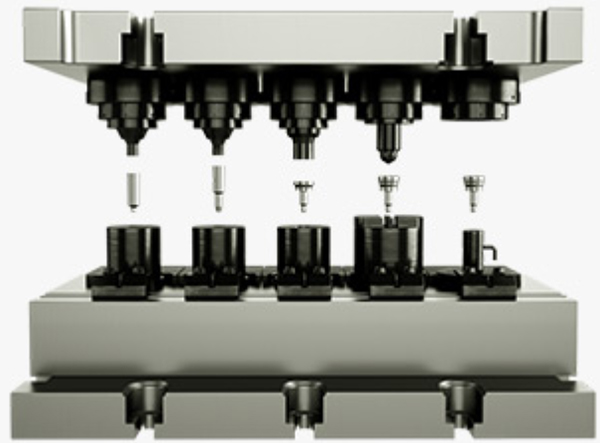

Multi-sequence Die Forging Hydraulic Press

Multi-sequence die forging hydraulic press is a multi-station synchronous forging equipment, suitable for forming special forgings, and can also be used for single-sequence forming and cold extrusion processes;

Servo control system, stable beat control, high energy saving;

Frame type fuselage guide structure, fast forging 2~5 processes, 3~30s/time forging speed, high forging accuracy;

Q355B material welded body, strong overall rigidity ;

Customized range 1~80MN, optional automatic centering device, automatic loading and unloading robot, stepping robot and other configurations.

Applicable to various forging products with simple and symmetrical shapes;

Small shaft, ring, cake, ingot, plate, sleeve, bearing processing;

Forging of various carbon steel, alloy steel, tool steel, bearing steel, spring steel, stainless steel and high temperature alloy steel;

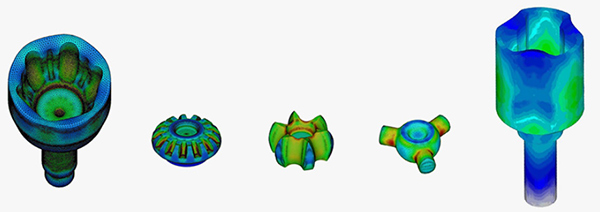

Multi-directional Die Forging Hydraulic Press

This series of hydraulic presses are designed with a frame structure, equipped with a main oil cylinder and a front, rear, left, and right horizontal cylinders, with stable force and high precision;

The structure is simple, the material utilization rate is high, most forgings are formed at one time, and the production cost is reduced;

Speed 50~400mm/S, synchronous extrusion with side cylinder ; The body is welded with Q355B material, with strong overall rigidity ;

The main forming products have high precision and no forging die taper ; Using servo control system, high energy saving;

Applied to various products with complex shapes and large quantities;

Suitable for various valve bodies, pipe joints, end joints, disc shaft assemblies and other forgings;

Suitable for forging of various carbon steel, copper, aluminum and alloy steel materials;

It can be directly configured with hot punching manipulator and intermediate frequency furnace to realize fully automated molding ;

Product detail pictures:

Related Product Guide:

"Control the standard by the details, show the toughness by quality". Our firm has strived to establish a highly efficient and stable workers workforce and explored an effective high-quality management system for china hot forging factory – Hot Forging Hydraulic Press – Zhengxi , The product will supply to all over the world, such as: Greece, Adelaide, Chile, We will continue to devote ourselves to market & product development and build a well-knit service to our customer to create a more prosperous future. Please contact us today to find out how we can work together.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.