Theakinder ƙarshen shine ƙarshen murfin a kan jirgin ruwa mai matsin lamba kuma shine babban kayan matsin lamba na jirgin ruwa mai matsin lamba. Ingancin kai yana da alaƙa kai tsaye ga dogon lokaci mai lafiya da abin dogara aiki na jirgin ruwa mai matsin lamba. Yana da mahimmanci kuma muhimmin bangare ne a cikin kayan aiki na jirgin ruwa a cikin petrochemicals, Atomic makamashi, abinci, sauran masana'antu.

A cikin sharuddan siffar, za a iya raba kawunan zuwa kawunan lebur, kawunan wanki, shugabannin oval, da shugabannin sperical. Shugabannin tasoshin tasoshin ruwa da kuma bloilers galibi suna da kwararru, kuma ana amfani da kai mafi yawa don matsin lamba na sama da sama. Kadan ne kawai wasu adadin tasoshin jiragen ruwa masu karfin gaske suke amfani da kai.

1. Hanyar sarrafa kayan abinci

(1) Staming. Don daidaita da taro samarwa, latsa latsa lokacin farin ciki-diamita da ƙananan shugabannin suna buƙatar saiti da yawa na kai.

(2) juya. Ya dace da shugabannin-bakin ciki da na bakin ciki. Musamman ma a masana'antar sunadarai, wanda galibi ya shafi manyan-girma-girma, musamman dacewa sosai don zubewa. Kusan Oval shugabannin sun dace sosai da zube, yayin da ba a yawan amfani da kawunan abinci da kawunan jama'a ba su da wahala su latsa.

2. Kayan aikin sarrafa kayan aiki da kayan aiki

(1) kayan dumama: murhun gas. A halin yanzu ana amfani da humakin shinge na tabarma don dumama, kuma ana amfani da dumama mai ko mai yawa. Saboda ana nuna shi ta hanyar tsaftataccen konewa, babban aiki, sarrafa zazzabi mai sauƙi, da wahala a cikin rashi da kuma cin zarafi. Ya kamata a sandar wutar tashe-tashena tare da na'urar ta zazzabi da rakodin zazzabi

.

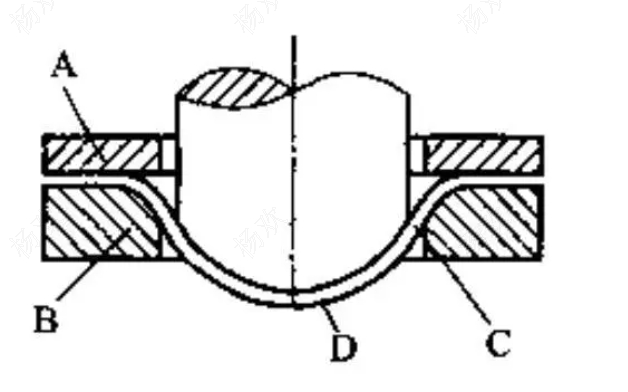

(2)Gasa ta ƙare danna. Akwai nau'ikan guda biyu: aiki-aiki da aiki biyu.

Guda guda yana nufin silin silin silinda kuma babu mai ɗaukar hoto mai riƙe da blank. Kawai ƙanana da matsakaici ne masu matsakaici suna amfani da shi. Manyan masana'antu duka suna amfani da mataki biyu, wato, akwai silinda mai riƙe da blank da siliki mai satar.

Matsakaiciyar watsa matsakaiciyar ta hydraulic Latsa ruwa ne. Yana da arha, motsawa da sauri, ba tsayayye, kuma ba shi da babban buƙatun katako kamar injin hydraulic. Ingancin yana ƙasa dalatsa hydraulic latsa, da kuma buƙatun ja-gorar ba tsaurara ba. Isar da watsawa na hydraulic latsa ya tabbata kuma yana da babban buƙatu don ɗaure da ja-gora.

(3) Yi amfani da kayan aiki, gami da nau'ikan nau'ikan kai da ƙananan molds da tallafi, da sauransu.

3. Abubuwa sun shafi lokacin farin ciki na kai

Yawancin abubuwan sun shafi canjin kai na kauri, wanda za'a iya taƙaita shi kamar haka:

(1) kaddarorin kayan. Misali, adadin thinning ya haifar da rufe bakin kai ya fi na Carbon hatimi.

(2) siffar shugaban. Shugaban mai siffa disped yana da mafi ƙanƙan adadin thinning, mai spherical yana da mafi yawan thinning, kuma shugaban Elliptical yana da adadin matsakaici.

(3) Mafi girma da radius na dishlet radius, karami adadin thinning.

(4) Mafi girma rata tsakanin babba da ƙananan ya mutu, ƙarami adadin thinning adadin.

(5) Yanayin lubrication yana da kyau kuma adadin bakin ciki karami ne.

(6) A mafi girman yawan zafin jiki, mafi girma adadin thinning.

4. Latsa kuma form the

(1) Kafin kowane kai ana matse shi, sikelin ominiya a saman blank dole ne a cire. Ya kamata a shafi lasricant ga mold kafin stamping.

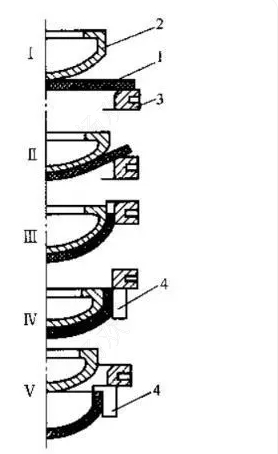

(2) Lokacin da latsa, ya kamata a sanya kai mai haske tare da mold da zai yiwu. Cibiyar ta karkacewa tsakanin blank da ƙananan mold yakamata ya zama ƙasa da 5mm. Lokacin danna shugaban da aka yi, ya kamata a biya shi don sanya buɗewar ellophtical a kan allon kamar tsayi da gajeren wando na ƙiren. A yayin matsar da matsakaitan, da farko, a daidaita da ramin da aka buga tare da lokacin buɗewar blank kuma tura. Tura shi zuwa wani ma'ana kaɗan fiye da jirgin saman mold (kimanin 20mm), sannan danna sama sama. Ramin Punch shima ya fadi a lokaci guda don latsa kai zuwa siffar. Yayin latsa, ƙarfin nau'i yana buƙatar a hankali ya ƙaru a hankali daga kananan kuma bai kamata a ƙara shi ba zato ba tsammani.

(3) Za a iya jan shugaban mai zafi daga ƙiyayya da kuma ɗaga lokacin da ya sanyaya ƙasa zuwa 600 ° C. Kada ku sanya shi a cikin iska. Kada a ajiye fiye da guda biyu a saman juna kafin sanyaya zuwa zazzabi a ɗakin. A lokacin ci gaba da hatimi, zazzabi da ya mutu ya tashi zuwa kusan kimanin 250 ° A° C da kuma belinka bai kamata a ci gaba ba. Aiki kawai zai iya ci gaba bayan an dauki matakan sanyaya don rage yawan zafin jiki na mutu.

(4) Ya kamata a kafa humble a mataki daya gwargwadon iko. A lokacin da ba shi yiwuwa a samar a lokaci guda saboda yanayin yanayin, ya kamata a biya agaji tare da kai a lokacin da aka biya ramin, da kuma kulawa ya kamata a biya ramin tufafi.

5.Ming Hydraulic Latsa

Yana da sauri kuma mai sassauƙa cikin kewayon aikace-aikace, yana da babban abin dogaro na samar da wadata, kuma yana da tattalin arziki da zartarwa.

■ Ya dace da matsakaicin matsin lamba mai zafi.

Tsarin latsa da ya dauki tsarin shafi huɗu.

Rike mai ɗaukar hoto yana sanye da adaftar adaftar.

■ bugun jini na silinda blank mai daidaitacce ne.

Ba a iya daidaita karfi da karfi da karfi da karfi ba za'a iya daidaita shi ta atomatik.

■ Shin zai iya fahimtar aiki guda ɗaya da aiki biyu bi da bi.

6

■ Dace don latsa latsa kai.

Tsarin latsa da ya dauki tsarin shafi huɗu.

Hadadden injin shimfiɗa sanye take da m mold, ƙananan mold, haɗin haɗi, haɗi na m, da na'urar sauri-na'urar.

Ba a iya daidaita karfi da karfi da karfi da karfi ba za'a iya daidaita shi ta atomatik.

Lokaci: Mayu-09-2024