Tare da cigaban ci gaba na kayan haɗi, ban da robobi masu karfafa Fiber-mai karfafa gwiwa, robobi masu karfafa gwiwa, da sauransu sun bayyana. Carbon fiber karfafa polymer hade (CFRP) abubuwa masu nauyi ne da karfi da ake amfani dasu don kera samfuran samfuran da muke amfani dasu a rayuwarmu ta yau da kullun. Kalma ce da aka yi amfani da ita wajen bayyana kayan Fiber-karfafa kayan kwalliya waɗanda ke amfani da fibers na carbon a matsayin babban kayan tsari.

Tebur na abun ciki:

1. Carbon fiber karfafa tsarin polymer

2. Hanyar da aka gyara na carbon fiber karfafa filastik

3. Kaddarorin carbon fiber karfafa polymer

4. Fa'idodi na CFRP

5. Rashin daidaituwa na CFRP

6. Carbon fiber karfafa amfani da filastik

Carbon fiber karfafa tsarin polymer

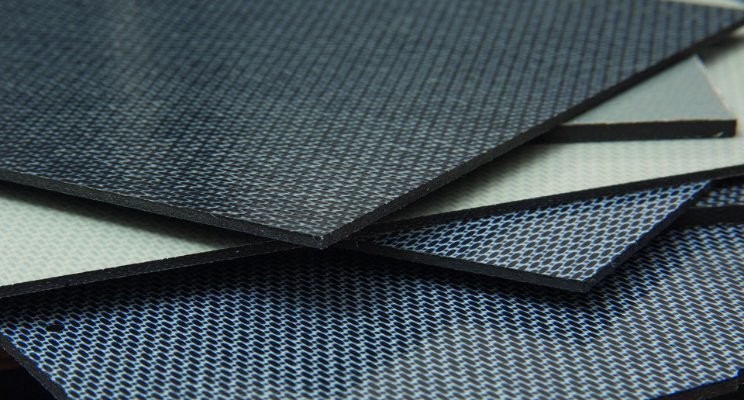

Carbon fiber reinforled filastik shine kayan da aka kafa ta hanyar shirya kayan fiber carbon a wani shugabanci da amfani da kayan polymer. Girman diamita na fiber carbon yana da bakin ciki, kusan 7 microns, amma ƙarfinta yana da matuƙar girma.

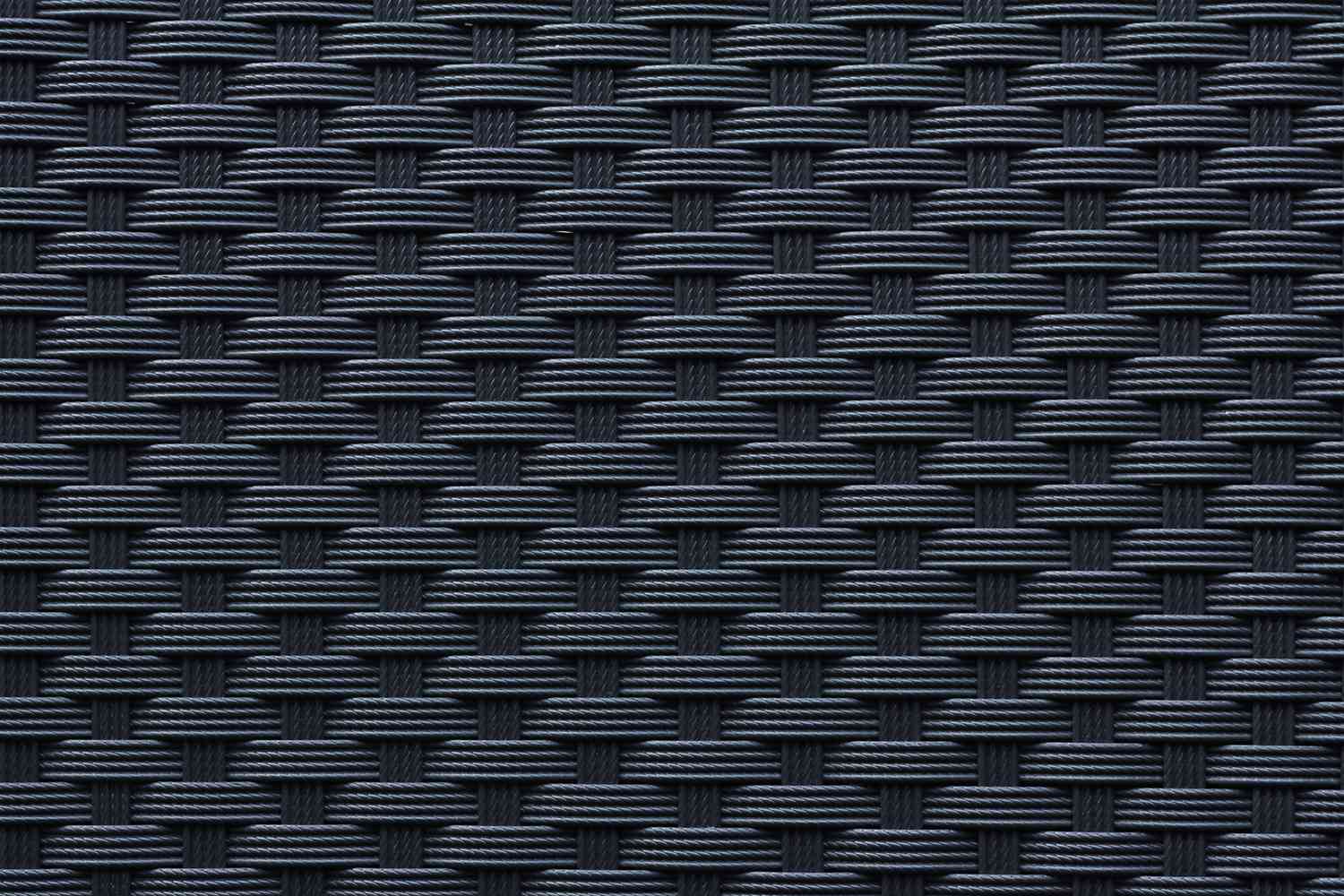

Mafi yawan naúrar yanki na Carbon fiber karfafa kayan kwalliya shine carbon fiber fiber fil. Ainihin albarkatun carbon filament shine prepoolder Polyackermerrile (pan), rayon, ko filin man fetur. Daga nan sai aka sanya filayen carbon a cikin masana'antar fiber carbon ta hanyar hanyoyin da na inji don ɓangarorin fiber carbon.

Mai ɗaure polymer yawanci shine reseretetet ɗin kamar yadda epoxy. Sauran Thermosets ko kuma makamancin thermoplastic wani lokacin ana amfani da su, kamar polyvinyl acetate ko nailan. Baya ga carbon zarbers, kwayar za ta iya ɗaukar nauyin suma, nauyi mai nauyi polyethylene, aluminum, ko zargin gilashi. Hakanan kaddarorin fiber fiber na karshe Carbon Carbon na Final Carbon na Final Carbon na Final Carbon na Final Carbon na Final Carbon na Final Carbon

Hanyar da aka gyara na carbon fiber karfafa filastik

Kayan fiber carbon galibi suna da bambanci saboda matakai daban-daban. Akwai hanyoyi da yawa don ƙirƙirar carbon fiber karfafa kayan polymer.

1. Hanyar hannu

Raba cikin hanyar bushewa (shagon da aka riga aka shirya) da hanyar rigar) (masana'anta fiber da resin glued don amfani). Hakanan ana amfani da hannun hannu don shirya shirye-shiryen amfani da su a cikin ayyukan sakandare kamar matsawa. Wannan hanyar shine inda zanen gado na fiber carbon an lalace akan mold don samar da samfurin karshe. Verfortharfin da taurin da aka samar da kayan da aka haifar ana inganta ta hanyar zaɓi jeri da kuma saƙa daga cikin firamb na masana'anta. To, a lokacin da aka cika da epoxy kuma warke tare da zafi ko iska. Wannan hanyar masana'anta ana amfani da ita sau da yawa don sassan da ba a jaddada, kamar murfin injin.

2. Workyirƙira Hanyar Hanyar

Ga Pigged Pigreged, ya zama dole don amfani da matsin lamba ta wani tsari don sanya shi kusa da ƙirar da magani da magani a ƙarƙashin wani zazzabi da matsi. Hanyar bagar ta wurin amfani da famfon mara kyau don motsa ciki daga cikin jakar foran don mummunar matsin lamba tsakanin jaka da kuma mold ya kafa matsin lamba don haka kayan aikin suna kusa da ƙirar.

Dangane da hanyar Bag, Veruum Bag-Pas-autoclave tsari an samo shi daga baya. Autoclaves suna ba da matsi mafi girma da warkar da sashin (maimakon magance yanayin halitta) fiye da jakar jakar ba kawai. Irin wannan wani bangare yana da ƙarin tsarin tsari, mafi kyawun ingancin iska, zai iya kawar da kumfa iska yadda ya kamata, kuma ingancin gabaɗaya ya fi girma. A zahiri, aiwatar da bagging ya yi kama da na fim ɗin wayar hannu mai suna. Cire kumfa iska babban aiki ne.

3. Hanyar molty

Matsawahanya ce mai ma'ana wacce ke haifar da taro da kuma samar da taro. Ana yin kayan molds yawanci da aka yi da manyan sassan, wanda muke kiran ƙirar mace da ƙirar mace. Tsarin haɗi shine a sanya matafar da aka yi da prepreas ɗin a cikin ƙirar ƙarfe, kuma a ƙarƙashin aikin wasu matsi da filastik, kuma yana cika matsin lamba, sannan kuma a cika matsin lamba da kuma magance samfuran. Koyaya, wannan hanyar tana da babban farashi na farko fiye da waɗanda suka gabata, tunda mold yana buƙatar injin CNC.

4. Winding mold

Ga sassa tare da sifofin hadaddun ko a cikin siffar jiki na juyin juya hali, ana iya amfani da iska ta filament don sanya sashin ta hanyar fitar da filament akan manoma ko cibiya. Bayan winding cikakken magani ne kuma cire mandrem. Misali, hanyoyin haɗin gwiwa na tubular sunyi amfani da su a tsarin dakatarwa ta amfani da wannan hanyar.

5. Gyara Canja wurin Motsa

Geson Canja wurin Mold (RTM) shine mafi mashahuri sanannen hanyar haɗi. Matakanta na asali sune:

1. Sanya masana'anta marasa kyau carbon fiber carbon a cikin mold kuma rufe mold.

2. Iya sanya resiyar da ruwa mai saukar da ruwa a ciki, impregnate don karfafa kayan, da magani.

Kaddarorin carbon fiber karfafa polymer

(1) babban ƙarfi da kyau elasticity.

Takamaiman karfi (wato, da karfin tensage zuwa yawan gaske) na fiber fiber shi sau 6 da sau shida cewa aluminum. A takamaiman modulus (wato, matsayin matasa na matasa zuwa yawa, wanda alama ce ta elasticity na wani abu) ya fi karfe sau da yawa da aluminum.

Tare da babban takamaiman ƙarfi, zai iya ɗaukar babban kaya mai aiki. Matsakaicin matsin aikinta na iya kai kilogram 350 kilogiram / cm2. Bugu da kari, ya fi sauran abubuwa da kuma sake jurewa da f-4 da kuma braid.

(2) kyakkyawan juriya da sa juriya.

Fataniyarta ce da ta fi girma fiye da gudummawa ta epoxy kuma sama da na kayan ƙarfe. Fibers Graphite suna ɗaukar mai-saƙa kuma suna da karancin tashin hankali. Yawan suturar shine 5-10 sau karami fiye da na samfuran ƙasa na asbestos ko f-4 braids.

(3) kyakkyawan aiki da hancin zafi da juriya.

Rufin Carbon na Carbon yana da kyawawan halayen da aka yiwa, kuma zafin rana ya haifar da rudani yana da sauƙin watsawa. A ciki ba shi da sauƙi ga overheat kuma adana zafi kuma ana iya amfani dashi azaman kayan sawun mai tsauri. A cikin iska, zai iya yin aiki mai ƙarfi a cikin yawan zafin jiki na -120 ~ 350 ° C. Tare da rage abun ciki na alkali a cikin fiber fiber, zazzabi sabis ya ƙara ƙaruwa. A cikin gas na Teert, zazzabi mai amfani zai iya kaiwa game da 2000 ° C, kuma yana iya yin tsayayya da canje-canje mai sanyi a cikin sanyi da zafi.

(4) juriya na rigakanci.

Ba shi da sauƙi a sake gwadawa ko flutter, kuma shi ne kuma kyakkyawan abu don ragewar rigakafin raguwa da ragi.

Abbuwan amfãni na CFRP

1. Haske mai nauyi

Mabalolin gilashin gilashi na gargajiya suna amfani da filayen gilashin gilashi da kuma zargin gilashin 70% (nauyin gilashi / duka nauyi) kuma yawanci suna da yawa) kuma galibi suna da yawa) kuma galibi suna da yawa) kuma yawanci suna da yawa) kuma yawanci suna da yawa) kuma yawanci suna da yawa) kuma yawanci suna da yawa) kuma yawanci suna da yawa) kuma galibi suna da yawa) kuma yawanci suna da yawa) kuma yawanci suna da yawa) kuma yawanci suna da yawa) kuma yawanci suna da yawa) kuma yawanci suna da yawa) kuma yawanci suna da fam of 0.065 fam a kowace inch inch. CFRP Haɗin da guda 70% na fiber a yawanci yana da yawa na 0.055 fam a kowace inch inch.

2. Babban ƙarfi

Kodayake carbon fiber karfafa karfafa polymers yana da nauyi mafi girma kuma mafi girma tauhidi a kowane bangare na kayan haɗin gilashi. Idan aka kwatanta da kayan ƙarfe, wannan amfani yafi bayyana.

Rashin daidaituwa na CFRP

1. Babban farashi

Kudin samar da carbon fiber karfafa filastik shi ne haram. Farashin fiber carbon na iya bambanta sosai dangane da yanayin kasuwa na yanzu (wadata da buƙata), nau'in carbon na carbon (aerbonpace vs. Matsayi A kan laban-laban-laban, tushen Budben na iya zama sau 5 zuwa sau 25 zuwa sau 25 fiye da fiber gilashi. Wannan bambancin ya fi girma yayin kwatanta karfe zuwa CFRP.

2. Ainihi

Wannan fa'idodi ne da hasara na carbon fiber parbon kenan. Ya dogara da aikace-aikacen. Fibers Carbon suna da matukar kulawa da gilashi masu ban sha'awa. Yawancin samfura suna amfani da fiberglass maimakon fiber na carbon ko ƙarfe saboda suna buƙatar rufin magudanar. A cikin samar da abubuwan amfani, samfura da yawa suna buƙatar amfani da zargin gilashi.

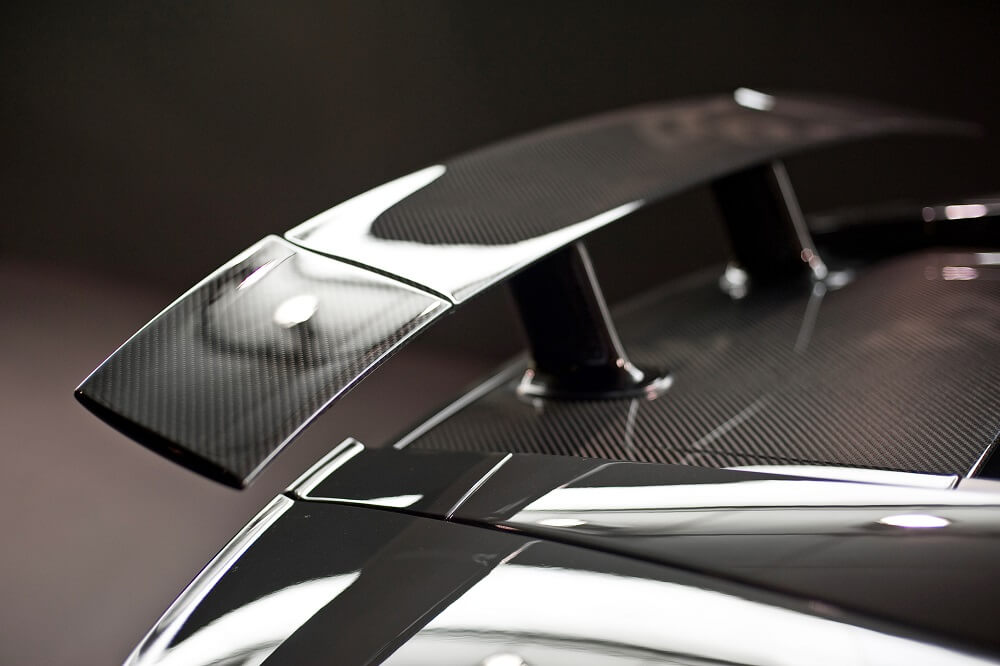

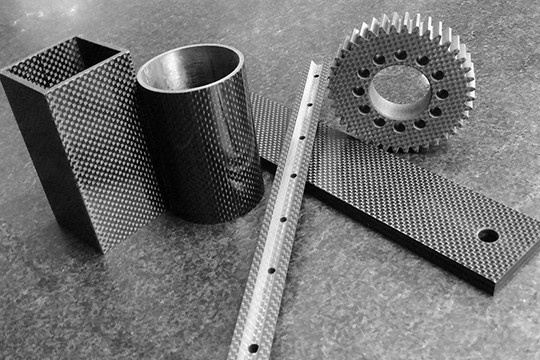

Carbon fiber karfafa amfani da filastik

Aikace-aikacen na Carbon fiber karfafa karfafa polymer suna da fadi a rayuwa, daga sassan inji ga kayan soji.

(1)Kamar yadda hatimin hatimi

Carbon fiber karfafa ptfe kayan za a iya sanya shi a cikin lalata-tsayayya, mai jure raunin zobba ko kuma shiryawa. A lokacin da aka yi amfani da shi don dogaro da suttura, rayuwar sabis ya fi, fiye da sau 10 sama da na gaba daya mai niyyar nutsuwa masu nutsuwa. Zai iya kula da hatimin da aka yi amfani da shi a cikin canje-canje da sauri da saurin dumama. Kuma tunda kayan bai ƙunshi abubuwan lalata ba, babu ɓarna mai lalata zuciya zai faru akan ƙarfe.

(2)Kamar yadda nika sassa

Yin amfani da kadarorin mai-sa-lubricating, ana iya amfani dashi azaman begings, gears, da piston zobba don dalilai na musamman. Irin asirin mai-mai kyauta don kayan aikin jirgin sama da masu rikodin tex, da sauransu na zubar da ruwa ta hanyar amfani da halaye na lantarki ta hanyar amfani da halaye na rashin guba ta hanyar amfani da halaye marasa guba.

(3) Kamar yadda kayan tsari don Aerospace, jirgin sama, da makamai masu linzami. An fara amfani da shi a masana'antar jirgin sama na jirgin sama don rage nauyin jirgin sama da haɓaka haɓakar jirgin. Hakanan ana amfani dashi a cikin sunadarai, man fetur, ƙarfin lantarki, kayan masarufi, da sauran masana'antu a matsayin kayan juyawa ko kayan haɗin kai tsaye.

Zhengxi kwararru neMasana'antar latsa na Hydraulic a China, samar da high-qulianyHydraulic Hydraulic latsaDon samar da samfuran CFRP.

Lokaci: Mayu-25-2023