Ku ƙyale shine sunan hadin kai don mantawa da kauri. Hanyar sarrafawa mai amfani da ita ce da ke amfani da guduma, anvil, da kuma naushi na mashin injin ko kuma mold ga matsin lamba akan blank don haifar da ƙurji don samun sassan filastik don samun sassan da ake buƙata da girma.

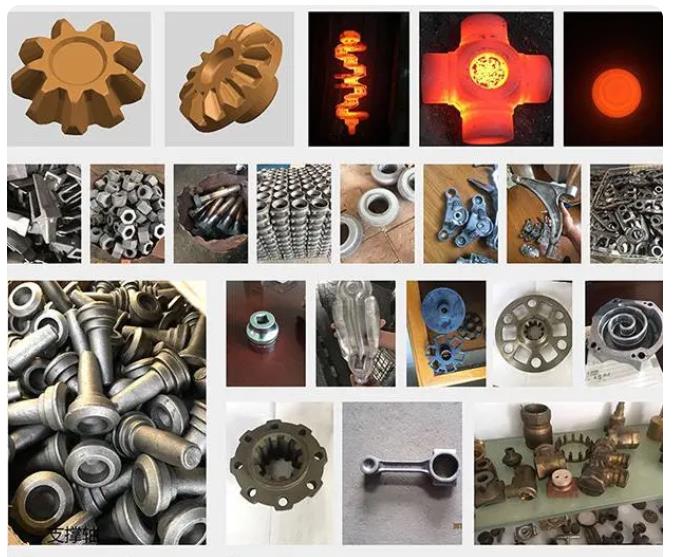

Abin da ya manta

A lokacin da ya kara m, daukacin blank ya yi fama da manyan filastik na filastik da kuma yawan adadin filastik mai gudana. A cikin tsarin hatimi, ana yawan kafa blank ta canza matsayin spatial na kowane yanki yanki, kuma babu filastikar filastik akan babban nisa a ciki. Karkatar da aka yi amfani da shi sosai don aiwatar da sassan ƙarfe. Hakanan za'a iya amfani dashi don aiwatar da wasu metals, kamar filastik na injiniya, roba, beram blic blanks, tubali, da kuma samar da kayan haɗin kayan.

Mirgita, zane, da sauransu a cikin masana'antu m masana'antu dukkanin filastik ko matsin lamba. Koyaya, ya manta ana amfani da shi don samar da sassan ƙarfe, yayin da aka yi amfani da kayan ƙarfe da zane-zane don samar da kayan kwalliya na musamman kamar faranti, tarko, bututu, bayanan martaba, da wayoyi.

Classification na marka

Ku ƙyale shi ne galibi a gwargwadon tsarin tsari da zazzabi. Dangane da hanyar da aka tsara, manta za a iya raba kashi biyu. Dangane da zafin jiki na nakasa, manta za'a iya raba shi cikin tsananin farin ciki, sanyi ka manta da m, m m, da kuma m m, da sauransu.

1. Matar zafi

Mai matuƙar jinƙai shine ya manta da yawan zafin jiki na ƙarfe. Arfara yawan zafin jiki na iya inganta filayen ƙarfe, wanda yake da amfani don inganta ingancin halayen kayan aikin kuma yana sa ba zai iya fashewa ba. Hakanan babban yanayin zafi na iya rage nakastar baƙin ƙarfe da rage abubuwan da ake buƙatamashin inji. Koyaya, akwai hanyoyin yin ƙyalli da yawa mai zafi, daidaitaccen aikin ba shi da kyau, kuma farfajiya ba ta santsi ba. Kuma abin da aka yi gãfara ne ga hadãwa, haƙĩƙa, da lalatar da kai. Lokacin da aikin aikin ya yi girma da kauri, kayan yana da babban ƙarfi da ƙananan filastik (kamar ana amfani da manyan sanduna na carbon, da sauransu), ana jin daɗin zafi.

Gabaɗaya da aka yi amfani da yanayin zafi mai ƙyalli. Alloy wani tsari na karfe 850 ~ 1150 ℃; Babban saurin ƙarfe 900 ~ 1100 ℃; Aluman aluminum siloy 380 ~ 500 ℃; Alloy 850 ~ 1000 ℃; Brass 700 ~ 900 ℃.

2. Cokali na sanyi

Cold ya manta shine marka da aka yi a ƙasa zazzabi sake dawowar ƙarfe. Gabaɗaya magana, sanyi mai ƙyalli yana nufin ƙyalli a ɗakin dakin da yake.

Ma'aikata da aka kafa ta hanyar sanyi ta kada ta manta da yawan zafin jiki da daidaitaccen yanayi, manyan matakai, kuma sun dace da samarwa ta atomatik. Yawancin colded da aka kirkira da kuma sanyi suttura stoped za a iya amfani da su azaman sassa ko samfuran ba tare da buƙatar injin ba. Koyaya, a lokacin sanyi mai sanyi, saboda tsananin filastik na ƙarfe, frows yana da sauƙi a faruwa lokacin nakasa da juriya da tsattsauran ra'ayi shine babba, suna buƙatar manyan kayan masarufi.

3. M ya manta

Ku ƙyale shi da zazzabi sama da zafin jiki na al'ada amma ba ya wuce zafin jiki na recrystallization ana kiran dumi m. Karfe yana faruwa, kuma yawan zafin jiki yana da ƙanƙanta fiye da na m jijirewa. M ya ji daɗi yana da daidaitaccen daidai, farfajiya mai narkewa, da ƙananan rashin juriya.

4. M ya kara burgewa

Ishunermal ya manta da yawan zafin jiki na blank lokacin duk tsari na forming. Ishunermal ya manta shine yin cikakken amfani da babban filastik na wasu ƙananan ƙananan ƙarfe a cikin zafin jiki ko don samun takamaiman tsarin da kaddarorin. Ishunermal ya manta da kyau da m abu abu a akai zazzabi, wanda ke buƙatar babban farashi kuma don ci gaba da ƙira na musamman.

Halaye na m

Kula da zai iya canza tsarin ƙarfe da haɓaka kaddarorin ƙarfe. Bayan ingot mai zafi ya ƙirƙira, pores, microes, micro-fasa, da sauransu a cikin jihar mai kama an haɗa su ko welded. Abubuwan dafaffen asali sun karye, suna yin hatsi. A lokaci guda, asalin carbide na asali da kuma rarraba marasa daidaituwa. Yi madaidaicin uniform, don samun cirewa da abubuwa masu yawa, uniform, lafiya, suna da kyau a gaba ɗaya aikin, kuma suna da aminci a amfani. Bayan an manta da abin da ya manta da jin daɗin jin daɗi, ƙarfe yana da tsarin fibrous. Bayan m ya gamsu da nakasa, rashin ƙarfe na ƙarfe ya zama tsari.

Ku ƙyale shi ne don sa ƙarfe ya kwarara a zahiri don samar da kayan aikin da ake so. Yawan ƙarfe baya canzawa bayan farkon filastik ya faru ne saboda ƙarfin waje, da ƙarfe koyaushe yana gudana zuwa ɓangaren juriya. A cikin samarwa, da yawan kayan aikin yawanci ana sarrafa su bisa ga waɗannan dokokin don cimma dawwama kamar thickening, elongation, fadada, da zane mai zurfi.

Girman formpece fa'idodin yana daidai kuma yana da damar shirya taro. Girman madaidaiciyar hanya a aikace-aikace kamar m ya manta, fashewa, da stamping daidai kuma baraka. Babban inganci mai gamsuwa da kayan masarufi da kuma za a iya amfani da layin samarwa ta atomatik don shirya taro na musamman ko samar da taro.

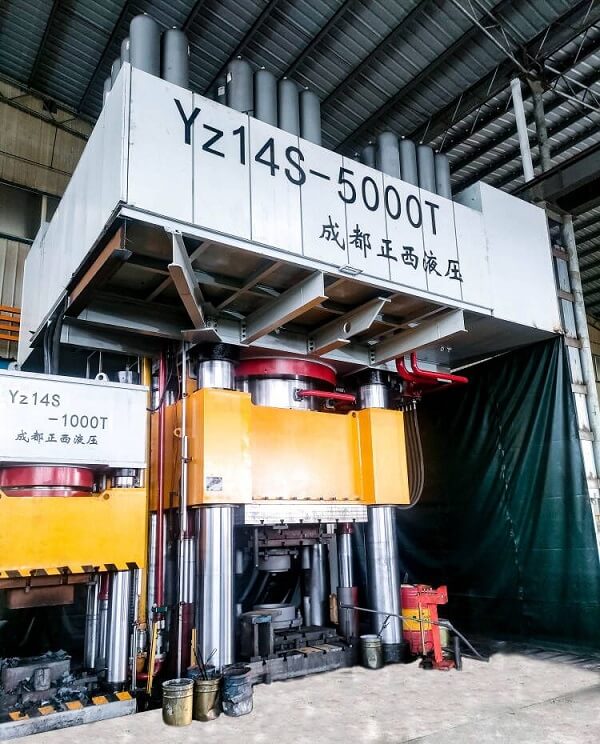

Ainihin amfani da injin da ya fi dacewa ya haɗa da hammers,Yanayin Hydraulic, da kuma wuraren da aka sarrafa. Gatmer na daular guduma yana da saurin tasiri, wanda ke da amfani ga kwararar ƙarfe na ƙarfe, amma zai haifar da rawar jiki. Latsa Hydraulic Latsa yana amfani da magana a tsaye, wanda yake da amfani da ya yiwa jan ƙarfe da inganta tsarin. Aikin ya tabbata, amma yawan aiki ya ragu. Latsa na inji yana da madaidaicin bugun jini kuma yana da sauƙin aiwatar da kayan aiki da aiki da kai.

Haɓaka Trend na Mahimmanci Fasaha

1) Don inganta ingancin ƙirƙira sassa daban-daban, galibi don inganta kayan aikin injin su (ƙarfin, filastik, ƙarfi, ƙarfin ƙarfi) da aminci.

Wannan yana buƙatar mafi kyawun aikace-aikacen ka'idar filastik na ƙananan ƙarfe. Aiwatar da kayan tare da ingancin inganci, kamar baƙi-bi da ƙarfe da injin-narkewa. Gudanar da dumama mai dumama da ƙyamar magani daidai. Mafi tsauraran abubuwa masu tsauri da wadatar da ba su da lalacewa.

2) ci gaba da ci gaba da ingantaccen fasahar magana da daidaitaccen fasaha. Gudanar da ba na yankewa ba shine mafi mahimmancin ma'auni da kuma hanyar masana'antu don haɓaka amfani da kayan aiki, haɓaka yawan aiki, kuma rage yawan makamashi, da rage yawan makamashi. Ci gaban dumama na rashin hawan katsewa, kazalika da high-wuya, mai tsayawa, kayan masarufi da kuma hanyoyin kulawa da ƙasa, za a riƙa kasancewa da sanya kayan masarufi na m ya gamsu da stamping.

3) Haɓaka kayan kwalliya da kuma kulla raguwar kayayyaki tare da samar da aiki da atomatik. A karkashin samar da kwastomomi, samar da aiki aiki ne sosai ingantacciyar inganta kuma m ƙaho an rage.

4) Ci gaban tsarin da ya dace da tsari (amfani da fasaha na rukuni, saurin mutu, da sauransu). Wannan yana ba da dama iri-iri, ƙananan-catchredmen samarwa don amfani da babban-atomatik da kayan aiki da kayan aiki da kaya ko kuma layin samarwa. Yi amfaninta da tattalin arziki kusa da matakin taro.

5) Haɓaka sabbin kayan, irin waɗannan hanyoyin sarrafawa na kayan foda na kayan foda (musamman ƙarfe ninki biyu, robobi mai ƙarfi, da sauran kayan ƙwadago. Haɓaka fasahar kamar superplastllic forplups, babban karfi-makamashi, da matsanancin matsin lamba na ciki.

Lokacin Post: Feb-04-2024