Me ka hoʻolālā mauʻana o nā mea hoʻohuihui e hoʻonui ai, i ka hoʻohuiʻana i nā plastics fiber-reintics, carbon fibers, etc.. Ua hoʻoikaikaʻia ko Carbon FlaG i nā pulupulu Pyomom (CFRP) ke kukui a me nā mea ikaika e hoʻohanaʻia e hana i nā huahana he nui. He hua'ōlelo i hoʻohanaʻia e wehewehe i nā mea hoʻohuihui fiber-reinpored e hoʻohana ai i nā kīlei carbon e hoʻohana ana i ka nui o nā carbon e like me ka mea nui.

TOFE ONTER:

1

2.ʻO keʻano o keʻano o ka carbon fiber reincoupted plastik

3.ʻO nā waiwai o ka carbon fiber i hoʻoikaikaʻia i ka polymer

4. Pono nā CFRP

5. Loaʻa nā hemahema o CFRP

6. Ua hoʻoponopono houʻia nā kālena Cardon

Ua hoʻoikaikaʻo Carbon Flam i ka hoʻolālā polymer

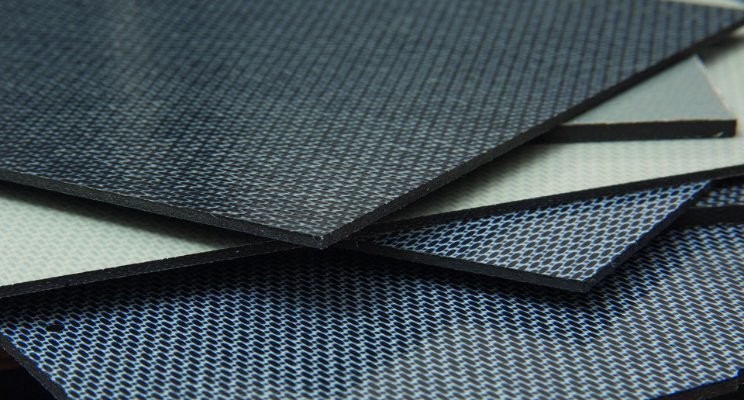

ʻO ka flabon flaber i hoʻoikaikaʻia i ka plastik i hanaʻia e ka hoʻonohonohoʻana i nā huahana carbon fiber ma kahiʻano a me ka hoʻohanaʻana i nā mea polyomer polyomer. He lae la ka alona o ke kolola o ka likona o ke kalana, ma ka 7 micons, aka ua nui kona ikaika.

ʻO ka papa inoa nui loa o ka papa o ka carbon fiber i hoʻoikaika i nā mea i hoʻohuiʻia i nā mea carbon carbon. ʻO ka waiwai nui o ka mea nui o ka carbon flalament he posolymer polyacrynelitrile (Pan), rayon, a iʻole ke kākela. Hanaʻia nā mea kīwī i loko o nā lole flabricles fubron ma nāʻano lāʻau lapaʻau a me nā mīkini hana no nā'āpana carbon no nā'āpana carbon.

ʻO ka polymer ka mea hana maʻamauʻo ia ka mea i mālamaʻia e like me ka epoxy. ʻO nā mea'ē aʻe a iʻole nā mea kākau moʻolelo a iʻole nā mea kākau moʻolelo i hoʻohanaʻia, e like me keʻanoʻo Pyvinyl Acetote a iʻole Nylon. Ma kahi o nā kīwaha colbon, hiki ke loaʻa nā posposites i ka Amid Q,ʻO Ultra-High Molecular Hiki ke hoʻopilikiaʻia nā waiwai o ka huahana carbon Falbon Falbon e hiki ke hoʻopilikiaʻia e keʻano o nā hoʻohui hoʻohui i hoʻokomoʻia i loko o ka bodrix.

ʻO keʻano o keʻano o ka carbon flaber reinchuced plastic

ʻO nā huahana carbon fiber heʻokoʻa ma muli o nā kaʻina likeʻole. Nui nāʻano hana no ka hoʻokumuʻana i nā carbon fiber i hoʻoikaika i nā mea polymer i hoʻoponoponoʻia.

1. Hana lima lima

Hoʻokaʻawale i ke ala maloʻo (hale kūʻai mua mua) a me keʻano o ka papa (ʻo keʻano o ka lole a me ka resin glod e hoʻohana). Ua hoʻohana pūʻia ka lima lima-up e hoʻomākaukau i nā prepregs no ka hoʻohanaʻana i nā kaʻina hana hou e like me keʻano e like me keʻano o keʻano. ʻO kēia ala kahi e pau ai nā'āpana o ka lole o ka carbon i kahi papa i kahi e hana ai i ka huahana hope loa. ʻO ka ikaika a me ka ikaika o nā waiwai o ka mea i manaʻoʻia e ka kohoʻana ma ke kohoʻana i ke kuleana a me nā kauʻana o nā frabrid fibers. Ua hoʻopihaʻia ka mold i ka epoxy a ho'ōlaʻia me ka wela a iʻole ka ea. Hoʻohana pinepineʻia kēiaʻano hana hana no nā'āpana koʻikoʻiʻole, e like me nā uhiʻenehana.

2.ʻO keʻanoʻano hana

No ka papa mua o Laminated Hoʻohana ka hana kīwī i kahi kīwī i hala e haʻalele ai i loko o kaʻeke i loko o kaʻeke a me ka molū maikaʻi i ke kaomiʻana i keʻano

Ma ke kumu o keʻano o ke kīpē i hoʻopaʻaʻia, keʻano o keʻano o keʻano o keʻano o ka hanaʻana ma hope. Hāʻawiʻo Autochoves i nā mea kiʻekiʻe a me nā wela wela i ka'āpana (ma mua o ka curing kūlohelohe) ma mua o nāʻano kīwī. ʻO kēlā'āpana kahi'āpana hou aku,ʻoi aku ka maikaʻi o ka maikaʻi, hiki ke hoʻopau i ka nui o nā pōpoki (ʻoi aku ka kiʻekiʻe o ka nui o ka nui. I kaʻoiaʻiʻo,ʻo ke kaʻina hana o ka hōʻai'ē pale e like me nā kiʻi kelepona kelepona kelepona paʻa. ʻO ka hoʻopauʻana i nā pulupulu ea he hana nui.

3

Ke kāohiʻanaheʻano movening e hana ana i ka hana nui a me ka hana nui. Hana pinepineʻia nā Molds i nā'āpana kiʻekiʻe a lalo, i kāhea aku ai mākou i nā kāne kāne a me ka wahine wahine. ʻO ke kaʻina hana e kau ai i ka Mat nā papa inoa o ka papa mua, a lalo hoʻi i ka hanaʻana o ka molū, a hoʻopiha hoʻi i ka pihi Eia nō naʻe,ʻoi aku ka kiʻekiʻe o kēia ala ma mua o nā mea mua ma mua o nā mea ma mua, mai ka wā e pono ai ka mold

4. Ke puhiʻana

No nā'āpana me nāʻano paʻakikī a iʻole keʻano o ke kino o keʻano o keʻano, hiki ke hoʻohanaʻia ka makani file ma keʻano o ke kāʻeiʻana i keʻano o ka papa Ma hope o ka hoʻopauʻana i ka holoiʻana i ka ho'ōla a wehe i ka mandrel. ʻO ka laʻana,ʻo nā lima hoʻokūkū Trut Rit i hoʻohanaʻia ma nā'ōnaehana hoʻokō hiki ke hana i kēiaʻano.

5. Hoʻomaʻamaʻa ka hoʻihoʻiʻana

ʻO ka hoʻihoʻiʻana i ke kāpaeʻana (RTM) heʻano hana maʻamau. ʻO kona mauʻano maʻamau:

1. E kau i ka mea i hoʻomākaukauʻia ai ka carbon barbon fibric bobric i ka pale a pani i ka neʻe.

2.ʻO keʻano o ka wai wai wai i loko o ia mea, e hoʻopiʻi i ka mea hoʻoikaika nuiʻana, a me ka ho'ōla.

ʻO nā waiwai o ka flaber caron

(1) ikaika kiʻekiʻe a me ka elasticity maikaʻi.

ʻO ka ikaika kiko'ī (ʻo ia hoʻi,ʻo ia ka pae o ka ikaika o ka ikaika o ka dinsile) o ka density. ʻO ka modulus kūikawā (ʻo ia hoʻi,ʻo ia ka pae o ka modulus o ka'ōpio,ʻo ia kahi hōʻailona o kahi mea iʻoi aku ma mua o 3 mau manawa a me ka alumini paha.

Me ka ikaika kiʻekiʻe, hiki ke hāpai i kahi ukana hana nui. Hiki i kona koʻikoʻi ke kiʻi nui loa i 350 kg / cm2. Eia kekahi,ʻoi aku ka maikaʻi a me ka mea kūʻai aku ma mua o ka hoʻomaʻemaʻeʻana f-4 a me kona lolo.

(2)ʻO ke kū'ē kino maikaʻi a me nā pale pale.

ʻOi aku ka nui o kona paleʻana i keʻano o ka mea eʻoi aku ma mua o ka mea epinxy resin aʻoi aku ka kiʻekiʻe ma mua o nā mea metala. ʻO nā kiʻi kiʻi kiʻi kiʻi iāʻoe iho e hana pono a loaʻa i kahiʻano liʻiliʻi o ka pā. ʻO ka nui o nā lole he 5-10 liʻiliʻi liʻiliʻi ma mua o nā huahana nui o nā huahana a iʻole nā b-4 braids.

(3)ʻO ka mālamaʻana i keʻano a me ke kū'ēʻana i ke kū'ēʻana.

Ua hoʻoikaika maikaʻiʻo Carbon Flam i nā Pladits Plastics heʻoluʻolu ʻAʻole maʻalahi keʻano o ka interior i luna a me ka wela wela a hiki ke hoʻohanaʻia e like me ka hōʻailona hōʻailona hōʻailona. I ka lewa, hiki iā ia ke hana ma ka pae o ka mahana o -120 ~ 350 ° C. Me ka hōʻemiʻana o nāʻikepiliʻo Alkali i ka Carbon Fiber, e hoʻonui houʻia kaʻoihana lawelawe. I loko o kahi kīwī i ka haunaele, hiki i kona wela kūpono e hiki ke loaʻa ma kahi o 2000 ° C, a hiki ke hoʻololi i keʻano o ka nui a me ka wela.

(4)ʻO ke kū'ē maikaʻi.

ʻAʻole maʻalahi ia e hoʻoponopono a kiʻi i keʻano a clipter, a he kumu no nā ala hoʻokiʻekiʻe loa a me ka hōʻemi wīwī.

Loaʻa i nā CFRP

1.ʻO ke kaumaha kukui

ʻO nā kiʻi kiʻi kiʻi kiʻi kiʻi kiʻiʻia e hoʻohana i nā plastics e hoʻohana mau ana i nā poli aniani a me 70% ʻO kahi hui cfrp me ka like like me 70% mau paona o ka paona he 7055 mau paona no 0.055 mau paona no ka helu cubic inch.

2, ikaika kiʻekiʻe

ʻOiai keʻano o ka caron caron i hoʻoikaika i ka māmā, he ikaika kiʻekiʻe aʻo CFRp i loaʻa ke kiʻekiʻe kiʻekiʻe a kiʻekiʻe loa ma mua o ke kaupaonaʻana o nā aniani Hoʻohālikelikeʻia me nā mea metala,ʻoi aku ka maopopo o kēia pono.

Loaʻa i nā hemahema o CFRP

1.

ʻO ka uku hana hana o ke kumukūʻai o ka carbon flaber reincoupted profile plastic. Hiki i nā kumukūʻai o Carbon Flage ke hoʻololi i keʻano o nā kumu kūʻai mākeke o kēia manawa Ma kahi kumu pouna ʻOi aku ka nui o kēiaʻokoʻa inā ke hoʻohālikelikeʻana i ke kila i cfrp.

2. Ke ola

ʻO kēia ka mea maikaʻi a me nā hemahema o nā mea hoʻohui carbon fiber. Aia ia i ka noi. ʻO nā mea kūʻai aku nā carbon e hana nui ana a me nā file mau aniani. He nui nā huahana e hoʻohana ai i ka fiberglass ma kahi o ke kalaka a iʻole ke kīwaha no ka mea ua koi lākou i ka subgent strike. I ka hanaʻana o nā mea pono, makemake nā huahana he nui i ka hoʻohanaʻana i nā kīʻaha o ke aniani.

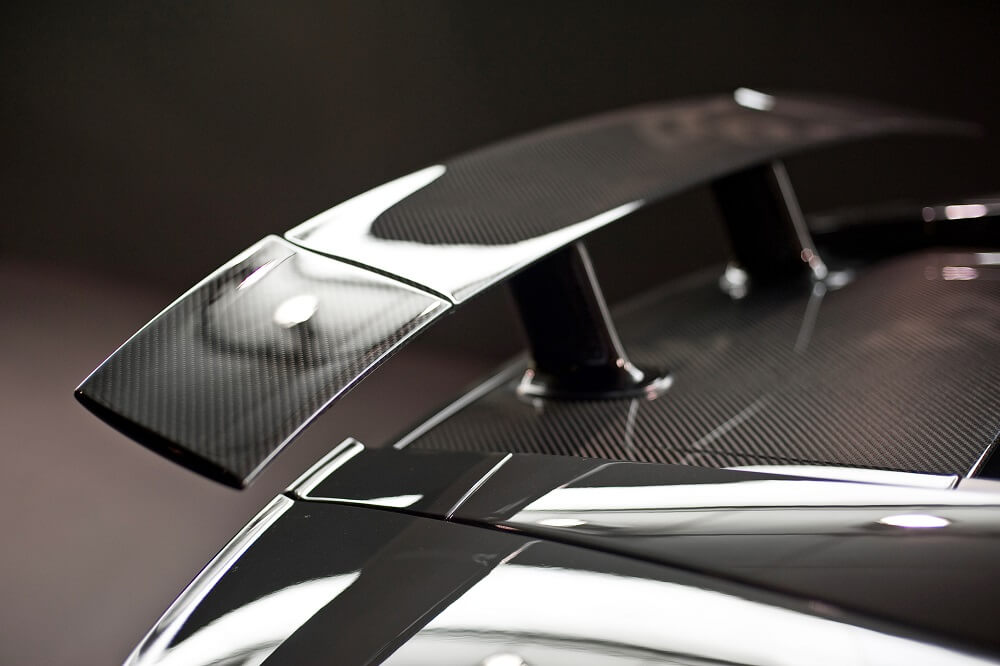

Ua hoʻoponopono houʻo Carbon Flam i nā hoʻohana plastik

ʻO nā noi o ka carbon flaber i hoʻoikaikaʻia i keʻano o ka polymer i ke ola, mai nā mea mīkini i nā pūʻali koa.

(1)E like me ke kohoʻana

Hiki ke hoʻopaʻaʻia nā kaʻa kaʻa o Carbon i nā mea ptfe i loko o ka corrosion-resistant,ʻaʻahu, a me keʻano kiʻekiʻe-noho kiʻekiʻe. I ka wā e hoʻohana ai no ke kauʻana o ka static,ʻoi aku ka lōʻihi o ke ola o ka lawelawe,ʻoi aku ma mua o 10 mau manawaʻoi aku ka lōʻihi Hiki iā ia ke mālama i ka hanaʻana i ka hana ma lalo o nā hoʻololiʻana o ka hoʻoukaʻana a me ka wikiwiki wikiwiki a me ka wikiwiki. A mai ka wāʻaʻole i loaʻa nā mea i nā mea hoʻoponopono kūponoʻole,ʻaʻohe mea e hoʻopili pono ai i ka corrosion ma ka metala.

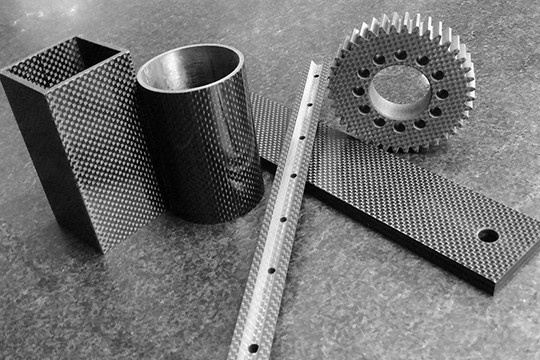

(2)Me nā'āpana'ōpala

Hoʻohanaʻo ia i kāna mau waiwai pilikino pono'ī, hiki ke hoʻohanaʻia e like me nā mea e lilo ai, nā gears, a me nā apo piston no nā kumu kūikawā. E like me nā mea e pili ana i nā mea hana i nā mea hana a me nā mea hana i nā mea kanu kīwī a iʻole nā mea hana i nā mea kanu kīwī.

(3) E like me nā mea hana no ka aerospace, agiation, a me nāʻiʻo. Ua hoʻohana muaʻia ia ma ka mokulele mokulele e hōʻemi i ke kaumaha o ka mokulele a hoʻomaikaʻi i ka hana o ka mokulele. Ua hoʻohanaʻia ma loko o ka cultical, petroleum, ka mīkini uila, a me nāʻoihana'ē aʻe e like me nā mea kūʻai aku paha

ʻO Zhengxi kahi loeaʻO Hydraulic Press Workout ma Kina, e hoʻolako i ka kiʻekiʻe-quliniatyʻO ka paʻiʻana i ka Domdsulic hydraulicno ka hanaʻana i nā huahana CFRP.

POST manawa: Mei-25-2023