ʻO ke kalaʻana ka inoa hōʻiliʻili no ke kalaʻana a me ke kiʻiʻana. Heʻano hana hana e hoʻohana ana i ka hammer

He aha ke kalaʻana

I ka wā o ke kalaʻana i ke kalaʻana, nā mea āpau āpau i lalo o ka nānāʻana i nā mea hoʻohui nui I ke kaʻina hana e hiki ai, ua hana ka palaka i ka hoʻololiʻana i ke kūlana Spatalia no kēlā wahi ākea, aʻaʻohe wai wai ma loko o kahi ākea nui i loko. Ua hoʻohana nuiʻia ke kalaʻana i nā'āpana metala. Hiki ke hoʻohanaʻia e hana i kekahi mau meaʻoleʻole, e like me nā plasties ma nāʻenehana, nāʻala, nā pōpeku nā mea hoʻohui.

RILLLLIY, kiʻi, etc. i ke kalaʻana a me nāʻoihana metallirgrical a iʻole ka hoʻoiliʻana a iʻole ke kaʻinaʻana. Eia naʻe, ua hoʻohana nuiʻia ke kalaʻana e hana i nā'āpana metala,ʻoiai ke heleʻana a me ke kiʻiʻana i nā papa he nui, nā papa hana, a me nā pale.

Ka papa o ka hoʻopoinaʻana

ʻO ke kalaʻana i ka helu nuiʻia e like me ka hanaʻana i keʻano a me keʻano deformation. E like me keʻano hana, hiki ke kalaʻia i nā'āpanaʻelua: ke kalaʻana a me ka stamping. E like me ka mahana deformation, hiki ke kalaʻia i ke kalaʻana i ke kalaʻana, ke kalaʻana, e hōʻoluʻolu, a me ke kalaʻana, etc.

1

ʻO ke kalaʻana i ke kalaʻana ke kala aku i luna ma luna o keʻano o ka mea hoihoi o ka metala. Ke hoʻonui nei i ka hoʻonuiʻana i ka mahana e hoʻomaikaʻi i ka palaualelo,ʻo ia ka mea pono e hoʻomaikaʻi ai i ka maikaʻi o ka hana a me ka hoʻowalewaleʻana. Hiki i nā kiʻekiʻe kiʻekiʻe ke hōʻemi i ka paleʻana o ka deformation o ka metal a hōʻemi i ka tonnage o ka ponoNA PALAPALANA. ^. Eia nō naʻe, he nui nā kaʻina hana iʻole aku nei, ilihune ka papa hanaʻo ka Workoisece, aʻaʻole ia e maʻemaʻe. A ua poleha nā elī i ka hoʻoweliweli, e hoʻonāoʻa ana, a hōʻino i ka hōʻino. I ka nui a me ka mānoanoa a me ka mānoanoa,ʻoi aku ka ikaika o ka waiwai a me ka haʻahaʻa haʻahaʻa (e like me keʻano o ka carbon calle kiʻekiʻe.

ʻO ka maʻamau maʻamau i hoʻohana i nā ho'ēmiʻana i nā mahana wela:ʻo ka mākeke carbon 800 ~ 1250 ℃; Alona orlos ortor Comel 850 ~ 1150 ℃; ʻoi aku ka wikiwiki o ke ala kiʻekiʻe 900 ~ 1100 ℃; Hoʻohana pinepine a Alminim Aly 380 ~ 500 ℃; alloy 850 ~ 1000 ℃; keleawe 700 ~ 900 ℃.

2, ke kalaʻana i ke anuanu

Ke kalaʻana i ke anuanu ke kalaʻana i ka hana ma lalo o ka mahana o keʻano o keʻano o keʻano o ka mea kūʻai aku. ʻO ka'ōlelo maʻamau, e'ōlelo ana, ke kalaʻana i keʻano o ke kalaʻana i ke kalaʻana i ka mahana o ka lumi.

Ua hanaʻia nā hana hana ma keʻano o ke anuanu i keʻano o ka lumi o ke keʻena a me nā papa hana kūpono, a kūpono i nā hana hana, a kūpono no ka hanaʻana. Nui nā'āpana maloʻo nui a me ke anuanu e hiki ke hoʻohanaʻia e hoʻohanaʻia e like me nā'āpana a iʻole nā huahana me ka ponoʻole o ka pono. Eia naʻe, i ka wā o ke kalaʻana, ma muli o keʻano haʻahaʻa o ka metala, he mea nui ka cracking i ka wā e hopohopo nui ai ka deformation.

3

Ke kalaʻana ma ke kiʻekiʻe kiʻekiʻe ma mua o ka mahana maʻamau akāʻaʻole iʻoi aku ka nui o keʻano o keʻano o keʻano o ke kalaʻana. ʻO ka mea hao e hoʻomoeʻia, aʻo ka wela o ka wela eʻoi aku ka haʻahaʻa ma mua o ka pauʻana o ka wela. ʻO ke kalaʻana i ke kalaʻana heʻoi aku ka nui, heʻano spether, a me nā pale haʻahaʻa haʻahaʻa.

4.ʻO ke kalaʻana i ke kalaʻana

Ua mālamaʻo Isthertual e mālama i ka wela o ka mahana i ke kaʻina hana holoʻokoʻa. ʻO ke kalaʻana o ISOTHORMAL e hana i ka hoʻohana pihaʻana i ka mea nui o ka uluna kiʻekiʻe o kekahi mau metala ma keʻano like a iʻole e loaʻa ai nāʻano kiko'ī. ʻO ke kalaʻana i ke kalaʻana e mālama i ka pale a me nā mea maikaʻiʻole i ka mahana mau, e pono ke hoʻololi i nā kumukūʻai kūikawā

Nā hiʻohiʻona o ke kalaʻana

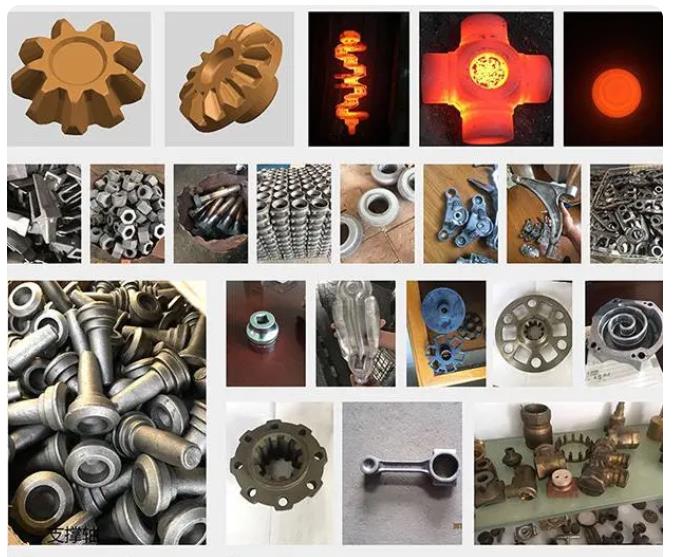

Hiki i ke kala ke hoʻololi i keʻano metala a hoʻomaikaʻi i nā waiwai metala. Ma hope o ka pauʻana o ke kīwī, ka pale mua, nā mea hana mua, nā micro-cracks, etc. ma ka hale kūʻaiʻia a paʻaʻole paha. Ua wāwahiʻia nā dendrites mua, e hana ana i ka nui o nā pā. I ka manawa like, ua hoʻololiʻia ka seggeration carbide mua a me ka hoʻokaʻawaleʻana o ka hoʻokaʻawaleʻana. E hana i ke kapa lole, e loaʻa nā kala e lilo ana i nā mea make, ka lole, maikaʻi, maikaʻi maikaʻi, a kūpono i ka hoʻohanaʻana. Ma hope o ke kalaʻana i ke kalaʻana e ke kalaʻana i ke kalaʻana,ʻo ka mea hao keʻano fibrous. Ma hope o ke kalaʻana i keʻano o ka hanaʻana, e lilo ana ka crystal metala.

ʻO ke kalaʻana e hana i ke kaheʻana o ke kīwaha i ka plastically e hana i kahi hana hana o keʻano makemake. ʻAʻole e loli ka nui o ka metala ma hope o ka hopena o ka wai ma muli o keʻano o waho, a me nā mea hao mau i ka'āpana me ka pale o ka mea liʻiliʻi. I ka hanaʻana, ua hoʻopiʻi pinepineʻia keʻano o ka hanaʻo ka hana hana e like me kēia mau kānāwai e hiki ai ke hōʻike ana i nā hana, e hoʻi pu ana, a heiku hāmeʻa.

ʻO ka nui o ka hana hana i hanaʻia he pololei a hanaʻia e hana pono e hoʻonohonoho i ka hana nui. ʻO nā'āpana o ka moding e hana ana i nā noi e like me ke kalaʻana, extrusion, a kūpono hoʻi a kūpaʻa. ʻO ka mālamaʻana i nā mīkini huna kiʻekiʻe a me nā hoʻololiʻana i nā laina huna a me nā laina e hoʻololi ai i nā laina hana e hiki ke hoʻohanaʻia e hoʻonohonoho i ka hana kūikawā a iʻole ka hana nui.

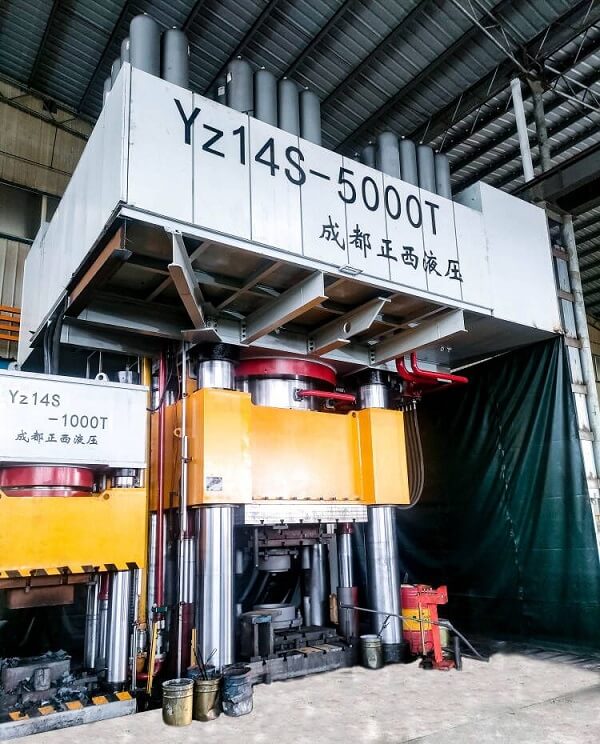

Hoʻohana pinepineʻia nā mīkini kala i nā mīkini e hoʻomālamalama i nā hammers,Nā Kūlana Hydraulic, a me nā mīkini paʻi. He wikiwiki ka wikiwiki o ka hommer i kahi wikiwiki nui,ʻo ia ka mea e pono ai i ka kahe o ka aila, akā e hana i ka viburation. ʻO ka mea e hoʻohana ai ka hydraulic i ka paleʻana o ka heluʻana,ʻo ia ka mea e pono ai e kala ana i ka metala a hoʻomaikaʻi i keʻano. Hoʻopiliʻia ka hana, akā haʻahaʻa ka huahana. ʻO ka mīkini mechanical e loaʻa kahi stroke paʻa a he maʻalahi ia e hoʻokō i ka hana a me ka automation.

ʻO ka hana hoʻomohalaʻana o ke kalaʻana i kaʻenehana

1) E hoʻomaikaʻi i ka maikaʻi o ka intrinsic o nā'āpana o nā'āpana,ʻoi aku ka hoʻomaikaʻiʻana i kā lākou mau mechanical (ikaika, ka ikaika.

Pono kēia i kahi noi maikaʻi loa o ka manaʻo o ka deformation plasticing o nā metala. E hoʻopili i nā mea waiwai me ka maikaʻiʻole maikaʻi, e like me ka mea i mālamaʻia e like me ka mea kila remuum E hana i ka hana muaʻana i ka hoʻomehanaʻana a me ke kalaʻana i ka mālama wela. ʻOi aku ka ikaika a me nā mea hoʻoweliweliʻoleʻole i ka hanaʻana i nā'āpana o nā'āpana.

2) E hoʻomohala hou i ka hana kūpono a me ke kaʻina hana kūpono. ʻO ka hoʻoiliʻana no nā mea hoʻihoʻiʻoleʻo ia ka mea nui a me ke kuhikuhi no nā hana mīkini e hoʻolauna ai i ka hana kuʻina Hoʻohana, a hōʻemi i ka waiwai hana hana. ʻO ka hoʻomohalaʻana o ka hoʻomehanaʻana i ka hoʻomehanaʻana i nā paleʻana, a me keʻano kiʻekiʻe, nā mea e ola ai a me keʻano o ke olaʻana i keʻano o ke ola

3) E hoʻomohala i nā mea hana e ho'ōla ai a me nā kalaʻana i nā laina hana me nā mea kiʻekiʻe a me nā automation. Ma lalo o ka hana hoʻolilo haʻahaʻa, hoʻomaikaʻi nuiʻia ka hana hana lāʻau a me ka kalaʻana i nā kumukūʻai e hōʻemiʻia ai.

4) E hoʻomohala i ka hoʻololiʻana i nā'ōnaehana hana (e pili ana i kaʻenehana hui Mālama kēia i nāʻano heihei-vartimet E hana i kona huahana a me kona waiwai e pili kokoke i ka pae o ka hana nui.

5) E hoʻomohala i nā mea hou, e like me ke kalaʻana i nāʻano hana o nā lako metallirgy (ʻoi aku ka nui. E hoʻomohala i nāʻenehana e like me keʻano superplastic

Post Time: Feb-04-2024