Tuam Tshoj Oem Tuam Tshoj SMC Manhole Npog Ntau Lawm Tshuab

Peb lub hom phiaj nrhiav kom pom cov txiaj ntsig zoo hauv tiam neeg thiab muab cov kev pabcuam zoo rau cov neeg siv khoom lag luam hauv tsev thiab txawv teb chaws tau ua tiav. Peb tau kuaj hauv tsev qhov chaw uas peb cov khoom siv raug kuaj xyuas txhua yam thiab txhua yam ntawm cov theem kev ua txawv. Muaj cov thev naus laus zis tshiab kawg, peb txhawb peb lub zeem muag nrog kev cai ua chaw tsim khoom.

Peb tsom nrhiav kom paub cov txiaj ntsig zoo hauv tiam neeg thiab muab cov kev pab cuam zoo tshaj plaws rau cov neeg siv khoom hauv tsev thiab txawv teb chaws kawg rauTuam Tshoj SMC Tshuab, NTAWV MOULDING cov tshuab, Kev ua haujlwm nyuaj kom ua kom ua tiav, kev tsim kho tshiab hauv kev lag luam, ua txhua yam rau kev ua lag luam thawj zaug. Peb sim peb qhov zoo tshaj plaws los tsim cov qauv kev tswj hwm kev paub, kom tsim cov khoom siv ntau lawm, tsim kev pabcuam ntau lawm, kom muab koj tsim tus nqi tshiab.

Zhengxi smc bmc hydraulic xovxwm tseem hu tau hydraulic comporites moulding xovxwm, nws tau thov hauv cov khoom siv compressating xws li SMC, BMC, FRP, GRP thiab li ntawd. Peb SMC txoj kev nias thiab nias muab cov kev lag luam sib xyaw ua ke Superiour ntau lawm muaj peev xwm ua tau, nrog rau kev kho thiab txhim kho kev xaiv. Peb tab tom muab cov kev cai tshiab ntawm cov kev cai hydraulic, thiab zhengxi aslo muab cov npe xaiv thiab txhim kho cov compression moulding molding nias ntawm txhua qhov ua thiab qauv. Peb cov xovxwm hydraulic yog siv los tsim ntau hom kev hloov kho tsheb tshiab, Aerospace, Industrial ETC.

Tshuab Nta

itit yog tsuas yog siv rau kev sib xyaw ua ke ntawm thermosetting (frp) plastics thiab thermoplastic khoom. Haum rau kev tsim cov SMC, BMC, DMC, GMT thiab lwm yam kev kub thiab cov ntawv txheeb thiab cov ntawv txheeb thiab cov ntawv txheeb thiab cov ntawv txheeb thiab cov ntawv txheeb thiab cov ntawv txheeb thiab cov ntawv txheeb thiab cov ntawv txheeb thiab cov ntawv txheeb thiab cov ntawv txheeb thiab cov ntawv txheeb thiab cov ntawv txheeb thiab cov ntawv txheeb thiab cov ntawv txheeb thiab cov ntawv txheeb thiab cov ntawv txheeb thiab cov ntawv txheeb thiab cov ntawv txheeb thiab cov ntawv txheeb thiab cov ntawv txheeb thiab cov ntawv txheeb thiab cov ntawv txheeb thiab cov ntawv txheeb thiab cov ntawv txheeb thiab cov ntawv txheeb thiab cov ntawv txheeb thiab cov ntawv txheeb.

Bryhyrd system yog ntsia rau saum nrog txij nkawm platform, ib puag ncig phooj ywg, cov suab nrov tsawg thiab muaj kev txij nkawm.

Kev siv hluav taws xob qeeb ceev nias tsim, tsim nyog tso tawm kom haum.

Txoj haujlwm ntawm kev ua haujlwm siab qeeb qhib pwm, haum rau cov khoom lag luam siab.

Functionick teb txog kev kaw lus, kev tswj hwm zauv.

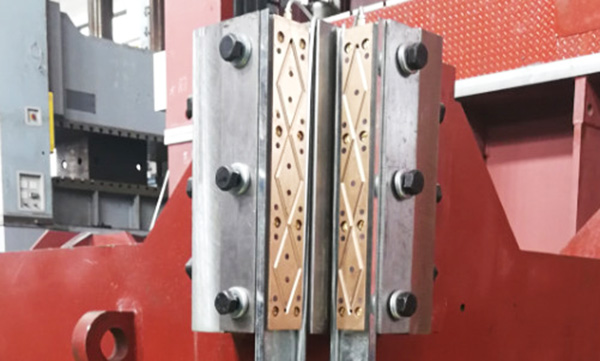

Ntawm qhov chaw daim duab

Cov Ntawv Thov

Lub tshuab no feem ntau haum rau cov khoom siv sib xyaw ua ke; Cov khoom siv muaj cov txheej txheem zoo rigidity thiab siab precision, lub neej siab thiab kev ntseeg siab. Cov txheej txheem rau cov xovxwm xovxwm sib yuav ua tau raws li 3 kev hloov pauv / hnub ntau lawm.

Cov Qauv Raug

| JB / T3818-99 "cov kev cai ntawm cov xovxwm hydraulic" |

| GB / T 3766-2001 "Kev Xav Tau Rau Cov Tshuab Hydraulic" |

| GB5226.1-2002 "Kev Nyab Xeeb Ntawm Machinery-Txhua Yam thiab Khoom Siv Hluav Taws Xob-Tshooj Yuav Tsum Tau" |

| GB17120-97 "Nias Cov Kev Nyab Xeeb Kev Nyab Xeeb Kev Nyab Xeeb Kev Nyab Xeeb" |

| JB9967-99 "Cov suab nrov hydraulic lub suab" |

| JB / T8609-97 "xovxwm machinery vuam kev mob" |

Kos Duab 3D

Tshuab tsis

Lub cev loj

Tus tsim ntawm tag nrho cov tshuab admts khoos phis tawj tsim kho thiab tshuaj xyuas nrog cov ntsiab lus zoo. Lub zog thiab rigidity ntawm cov khoom siv yog qhov zoo, thiab cov tsos yog qhov zoo. Tag nrho welded seem ntawm lub tshuab lub cev yog welded los ntawm cov khoom zoo me me ntawm zeb Q345B steel dioxide kom ntseeg tau cov vuam zoo.

Lub poom

| Qhov chaw | Fkev noj mov |

| Dej fais |

|

| PISTON QWS |

|

| Daim ntsaws ruaj ruaj | Txais cov lus Nyij Pooj NOK HOM Hmoov Zoo Realing Nplhaib |

| Piston | Coj los ntawm tooj liab plating, zoo hnav tiv taus, ua haujlwm ntev ntawm lub tog raj kheej |

Tus ncej

Cov phau ntawv qhia cov lus qhia (tus ncej) yuav ua los ntawmC45 Kub Forging SteelThiab muaj lub chrome tawv txheej tuab 0.08mm. Thiab ua kev kho mob tawv thiab kub. Cov kab ke ntawm tes tsho zoo tooj liab qhia lub tes tsho, uas yog ntau cov hnav-resistant thiab txhim kho qhov ruaj ntseg thiab txhim kho qhov ruaj khov ntawm lub tshuab

SERVO SYSTEM

1.Servo system muaj pes tsawg leeg

2.Servo system muaj pes tsawg leeg

| Lub npe | Mkua hlau | Pdaim xov xwm | Akev tseem ceeb |

| Hmi | Siemens |

| Lub neej ntawm lub khawm yog nruj me ntsis raug kuaj, thiab nws tsis puas los ntawm nias 1 lab lub sijhawm. Vijtsam thiab siv lub tshuab ua txhaum kev pab, piav qhia txog kev tshuaj ntsuam cov haujlwm, piav qhia lub tswb lub tshuab, thiab pab cov neeg siv khoom siv tau sai ntawm tshuab siv

|

| Lub npe | Mkua hlau | Pdaim xov xwm | Akev tseem ceeb |

| Plc | Siemens |

| Electronic pas ntsuas tus kav kav cov neeg tau txais cov kab yog ua tiav nws tus kheej, nrog muaj zog tiv thaiv kev cuam tshuam nrog kev cuam tshuam Digital tswj ntawm Servo tsav thiab kev koom ua ke nrog tus tsav |

| Servo Tsav Tsheb

| Yaskawa |

| Cov capital bascar tag nrho tau hloov kho dua tshiab, thiab lub capacitor nrog qhov kub lub neej hloov tau thiab siv lub neej kev ua haujlwm ntev dua li 4 zaug;

Cov lus teb ntawm 50MPA yog 50ms, lub siab overshoot yog 1.5kgf, lub sijhawm siab yog 60ms kev hloov pauv yog 0.5kgf.

|

| SERVO TSAV

| THASE Series |

| Lub simulation qauv tsim yog nqa los ntawm ansoft software, thiab lub tshuab hluav taws xob zoo dua, cov ua haujlwm siab yog qhov me me, ua haujlwm siab dua, thiab cov cua sov yog me dua;

|

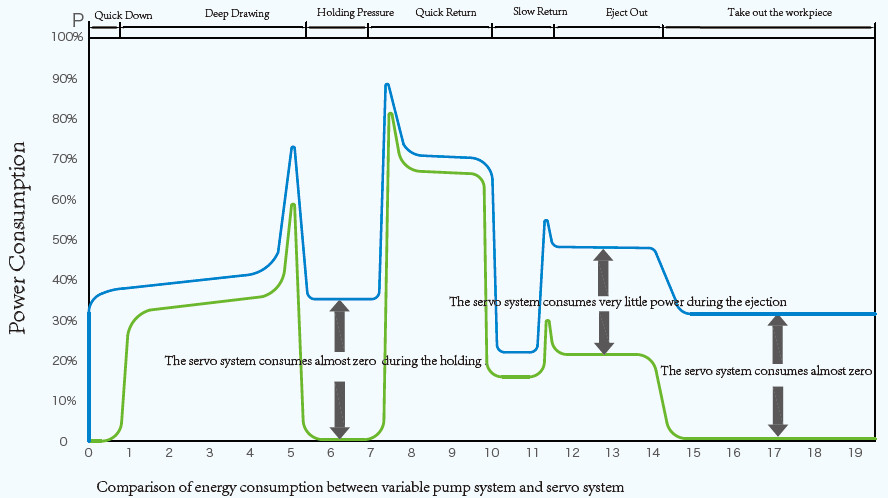

3.Advantages ntawm servo system

Zog Txuag

Piv nrog tso ib txwm sib deev system, servo roj twj tso cai cov yam ntxwv ntawm cov roj tsheb hydraulic, uas ua rau lub zog loj txuag lub peev xwm, thiab lub zogTxuag tus nqi tuaj yeem ncav cuag li 30% -80%.

Ua tau zoo

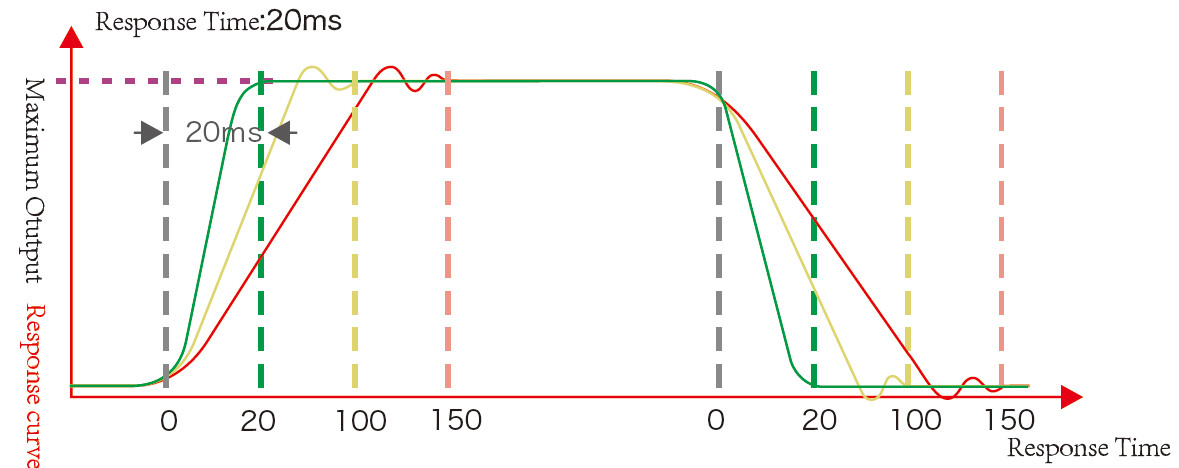

Cov lus teb ceev yog nrawm thiab lub sijhawm teb yog luv li 20ms, uas txhim kho cov lus teb ceev ntawm cov kab ke hydraulic.

Kev nplig

Cov lus teb nrawm nrawm tau lees tias kev qhib thiab kaw qhov tseeb tuaj yeem ncav cuag 0.1mm, thiab txoj haujlwm tshwj xeeb txoj hauj lwm raug± 0.01mm.

Lub siab-precision, high-teb pid algorithm module ua kom lub kaw lus ruaj khov thiab siab hloov pauv ntawm tsawg dua± 0.5 bar, txhim kho cov khoom lag luam zoo.

Kev tiv thaiv ib puag ncig

Suab nrov: lub suab nrov nruab nrab ntawm cov hydraulic servo system yog 15-20 db qis dua li ntawm cov khoom nqus qub.

Qhov kub thiab txias: Tom qab cov roj servo yog siv, cov roj hydraulic yog txo kom tag nrho lub neej ntawm lub neej hydraulic lossis txo lub zog ntawm lub txias dua.

Khoom Siv Kev Ruaj Ntseg

Duab-hluav taws xob kev nyab xeeb saib xyuas pem hauv ntej & nram qab

Xaub Xauv Ntawm Tdc

Ob Txhais Tes Ua Si Sawv

Kev Pab Nyiaj Txhawb Kev Pov Hwm Hob

Kev tiv thaiv ntau dhau: valve valve

Qib Qib Lub Tswb Tswb: Roj Theem

Roj ceeb toom txog kev kub ntxhov

Txhua qhov hluav taws xob muaj kev tiv thaiv ntau dhau

Kev Ruaj Ntseg

Xauv Cov Txiv Ntseej yog muab rau cov chaw tsoins

Txhua qhov kev txiav txim ntawm cov xovxwm muaj kev nyab xeeb muaj kev muaj nuj nqi, piv txwv li cov neeg txav chaw ua haujlwm yuav tsis ua haujlwm tshwj tsis yog lub zog yuav rov qab mus rau thawj txoj haujlwm. Swb tsis tuaj yeem nias thaum tso tau worktable yog nias. Thaum muaj kev sib cav ua haujlwm tshwm sim, lub tswb qhia ntawm kov screen thiab qhia qhov teeb meem dab tsi.

HYDRAUYyim CAV

1.Neloil tank tau teeb tsa lub tshuab cua txias (muaj phaj hom-hom dej txias

2.Qhov cov khoom siv hydraulic tau txais cov cartridge valtidge Valve Tswj system nrog cov lus teb nrawm nrawm thiab kub kis tau zoo.

3.Qhov roj tank yog nruab nrog cua lim sib txuas lus nrog cov roj sab nraud kom ntseeg tau tias cov roj hydraulic yog tsis tau qias neeg.

4.Qhov kev sib txuas ntawm lub puv valve thiab roj roj tank siv ib qho kev sib koom ua ke ntawm cov roj thiab daws tau qhov teeb meem ntawm cov roj xau.

Peb lub hom phiaj nrhiav kom pom cov txiaj ntsig zoo hauv tiam neeg thiab muab cov kev pabcuam zoo rau cov neeg siv khoom lag luam hauv tsev thiab txawv teb chaws tau ua tiav. Peb tau kuaj hauv tsev qhov chaw uas peb cov khoom siv raug kuaj xyuas txhua yam thiab txhua yam ntawm cov theem kev ua txawv. Muaj cov thev naus laus zis tshiab kawg, peb txhawb peb lub zeem muag nrog kev cai ua chaw tsim khoom.

Suav teb OEMTuam Tshoj SMC Tshuab, NTAWV MOULDING cov tshuab, Kev ua haujlwm nyuaj kom ua kom ua tiav, kev tsim kho tshiab hauv kev lag luam, ua txhua yam rau kev ua lag luam thawj zaug. Peb sim peb qhov zoo tshaj plaws los tsim cov qauv kev tswj hwm kev paub, kom tsim cov khoom siv ntau lawm, tsim kev pabcuam ntau lawm, kom muab koj tsim tus nqi tshiab.