Hlau Hmoov Rau Hydraulic Xovxwm

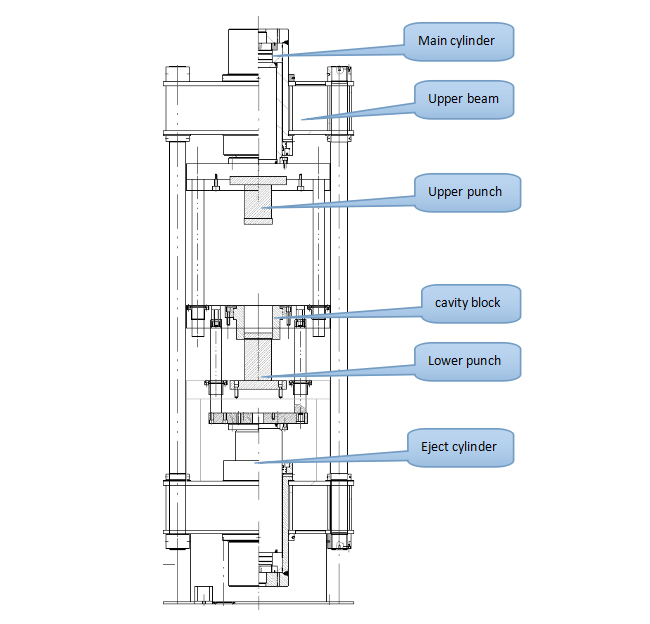

Pwm Ncej

1) Cov pwm hauv paus yog ua los ntawm 40Cr thiab 45 # steel los ntawm kev quav ntsej, tig thiab sib tsoo sib tsoo thiab sib tsoo kom muaj tseeb. Cov Lus Qhia Saib Cov Khoom Sib Ntaus Sib Ntaus Sib Ntaus Sib Txawv los tiv thaiv qhov chaw ntawm puas tsuaj, xws li Tooj Liab Qhia Tes Tsho. Nrog cr.

2) Lub puab tsaig sab sauv ntawm cov pwm ncej yog ib qho sab saud, thiab cov Punch sab saud yog ncaj qha rau sab saud; Tus poj niam cov poj niam muaj cov pwm nyob hauv cov qauv tsis zoo, thiab ob qho tib si floting supression thiab yuam kev ntab nrawm yog ua hauv cov txheej txheem nias. Kev xaiv tsa, "hmoov", ntab hluav taws xob, siab tuav ncua, siab tos qeeb, thiab lwm yam thaum nias. Thaum tsiv cov hmoov, lub sab saud thiab qis dua cov pwm tsis zoo yog ntab synchronously nrog rau sab saud.

3) qhov demoulding tus qauv muaj kev tiv thaiv thiab tiv thaiv demoulding rau kev xaiv; Tus poj niam pwm thiab undershoot muaj ib txhij muaj kev sib xyaw ua ke thiab cov poj niam pwm raug muab tso rau ncaj qha rau cov poj niam pwm tau zoo dua tiv thaiv cov khoom los ntawm kev puas yooj yim.

4) Pub qhov siab, cov khoom lag luam nias qhov siab thiab demoulding qhov siab thiab cov txheej txheem kev pab cuam tswj tau zoo, thiab nrog cov tshuab ntaus ntawv txwv.

5) Ib qho kev sib xyaw uas tsis yog xim hlau txuas ntawm cov khoom sib koom ua ke thiab cov khoom siv tsis sib xws, thiab txhua qhov hlau tsis muaj kev sib cuag nrog cov khoom siv raw.

Kev Pub System

1. Cov txheej txheem pub mis yuav muaj 6 tus neeg pw, thiab txhua plhaw yuav thauj khoom sib txawv cov khoom siv.

2.Qhov kev cia siab yuav hloov tau, thiab muaj kev sib khi zoo.

3.Qhov chaw thau khoom ntawm cov khoom nyoos, txhua 5-10 strokes.

4.Nyhopper Ua haujlwm kom muaj nuj nqis tuaj yeem ua rau HMI, 1,2,3 ... 10, ua haujlwm ua ke.

5.6 Hoppers loj yuav raug ntsia rau saum lub tshuab, txhua Hopper tuaj yeem thauj khoom 15 kg ntawm hmoov.

Tus ncej

Cov phau ntawv qhia cov lus qhia (tus ncej) yuav ua los ntawmC45 Kub Forging SteelThiab muaj lub chrome tawv txheej tuab 0.08mm. Thiab ua kev kho mob tawv thiab kub.

Cov Qauv Raug

JB / T3818-99"Cov Kev Mob Ntawm Cov Xovxwm Hydraulic"

GB5226.1-2002"Kev Nyab Xeeb ntawm cov tshuab-cov neeg kho tshuab thiab cov khoom siv hluav taws xob-Tshooj yuav tsum muaj"

GB / T 3766-2001"Kev Xav Tau Kev Siv Rau Cov Tshuab Hydraulic"

GB17120-97"Nias MACHINERYA kev nyab xeeb kev xav tau"

JB9967-99"Cov suab nrov hydraulic suab"

Lub cev loj

Tus tsim ntawm tag nrho cov tshuab admts khoos phis tawj tsim kho thiab tshuaj xyuas nrog cov ntsiab lus zoo. Lub zog thiab rigidity ntawm cov khoom siv yog qhov zoo, thiab cov tsos yog qhov zoo. Tag nrho welded seem ntawm lub tshuab lub cev yog welded los ntawm cov khoom zoo me me ntawm zeb Q345B steel dioxide kom ntseeg tau cov vuam zoo.

Lub poom

| Qhov chaw | Fkev noj mov |

| Dej fais |

|

| PISTON QWS |

|

| Daim ntsaws ruaj ruaj | Txais cov lus Nyij Pooj NOK HOM Hmoov Zoo Realing Nplhaib |

| Piston | Coj los ntawm tooj liab plating, zoo hnav tiv taus, ua haujlwm ntev ntawm lub tog raj kheej |

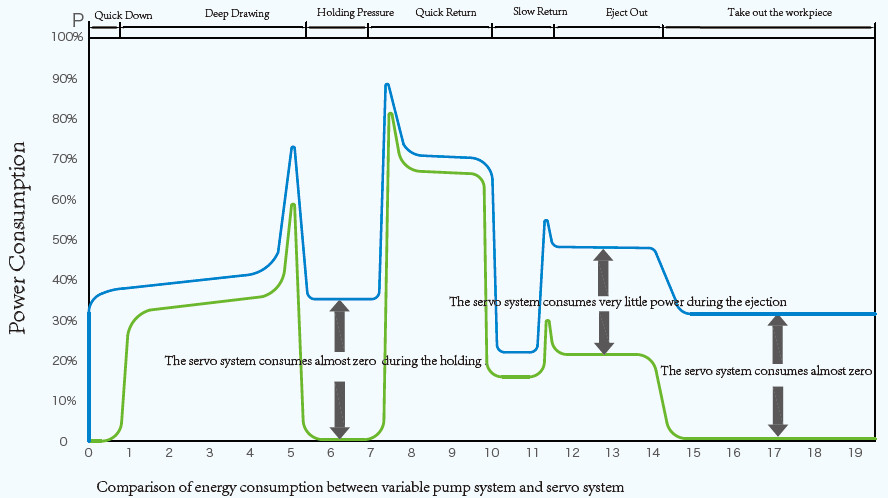

SERVO SYSTEM

1.Servo system muaj pes tsawg leeg

2.Advantages ntawm servo system

Zog Txuag

Piv nrog tso ib txwm sib deev system, servo roj twj tso cai cov yam ntxwv ntawm cov roj tsheb hydraulic, uas ua rau lub zog loj txuag lub peev xwm, thiab lub zogTxuag tus nqi tuaj yeem ncav cuag li 30% -80%.

Ua tau zoo

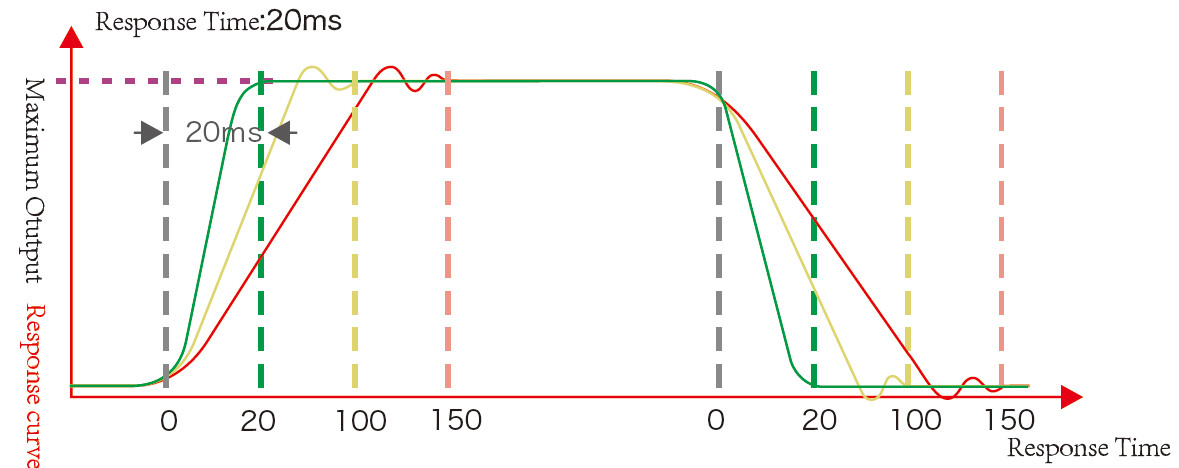

Cov lus teb ceev yog nrawm thiab lub sijhawm teb yog luv li 20ms, uas txhim kho cov lus teb ceev ntawm cov kab ke hydraulic.

Kev nplig

Cov lus teb nrawm nrawm tau lees tias kev qhib thiab kaw qhov tseeb tuaj yeem ncav cuag 0.1mm, thiab txoj haujlwm tshwj xeeb txoj hauj lwm raug± 0.01mm.

Lub siab-precision, high-teb pid algorithm module ua kom lub kaw lus ruaj khov thiab siab hloov pauv ntawm tsawg dua± 0.5 bar, txhim kho cov khoom lag luam zoo.

Kev tiv thaiv ib puag ncig

Suab nrov: lub suab nrov nruab nrab ntawm cov hydraulic servo system yog 15-20 db qis dua li ntawm cov khoom nqus qub.

Qhov kub thiab txias: Tom qab cov roj servo yog siv, cov roj hydraulic yog txo kom tag nrho lub neej ntawm lub neej hydraulic lossis txo lub zog ntawm lub txias dua.

Khoom Siv Kev Ruaj Ntseg

Duab-hluav taws xob kev nyab xeeb saib xyuas pem hauv ntej & nram qab

Xaub Xauv Ntawm Tdc

Ob Txhais Tes Ua Si Sawv

Kev Pab Nyiaj Txhawb Kev Pov Hwm Hob

Kev tiv thaiv ntau dhau: valve valve

Qib Qib Lub Tswb Tswb: Roj Theem

Roj ceeb toom txog kev kub ntxhov

Txhua qhov hluav taws xob muaj kev tiv thaiv ntau dhau

Kev Ruaj Ntseg

Xauv Cov Txiv Ntseej yog muab rau cov chaw tsoins

Txhua qhov kev txiav txim ntawm cov xovxwm muaj kev nyab xeeb muaj kev muaj nuj nqi, piv txwv li cov neeg txav chaw ua haujlwm yuav tsis ua haujlwm tshwj tsis yog lub zog yuav rov qab mus rau thawj txoj haujlwm. Swb tsis tuaj yeem nias thaum tso tau worktable yog nias. Thaum muaj kev sib cav ua haujlwm tshwm sim, lub tswb qhia ntawm kov screen thiab qhia qhov teeb meem dab tsi.

HYDRAUYyim CAV

1.Neloil tank tau teeb tsa lub tshuab cua txias (muaj phaj hom-hom dej txias

2.Qhov cov khoom siv hydraulic tau txais cov cartridge valtidge Valve Tswj system nrog cov lus teb nrawm nrawm thiab kub kis tau zoo.

3.Qhov roj tank yog nruab nrog cua lim sib txuas lus nrog cov roj sab nraud kom ntseeg tau tias cov roj hydraulic yog tsis tau qias neeg.

4.Qhov kev sib txuas ntawm lub puv valve thiab roj roj tank siv ib qho kev sib koom ua ke ntawm cov roj thiab daws tau qhov teeb meem ntawm cov roj xau.