1. Kev zam txim pub dawb

Kev zam txim pub dawb yog hais txog kev ua cov txheej txheem ntawm kev siv cov cuab yeej yooj yim-hom phiaj los cuam tshuam nrog cov khoom siv sab saud thiab sab nraud kom tau txais cov duab geometric uas yuav tsum muaj.

Kev zam txim pub dawb tsuas yog ua kev zam txim hauv cov khoom me me. Forging khoom xws li fwm rau rauj thiab hydraulic xovxwm yog siv los ua cov seem kom tau txais kev zam txim uas tsim nyog. Tso cai pub dawb los lees txais cov qauv forging forging.

Cov txheej txheem forging pub dawb suav nrog cov txheej txheem yooj yim, txheej txheem ib pab txheej txheem, thiab cov txheej txheem ua tiav.

Cov txheej txheem yooj yim ntawm kev pub dawb yog chim siab, kos duab, tsoo, sib dhos, thiab lwm yam kev lom zem heev yog chim siab, kos duab, thiab xuas nrig ntaus.

Auxiliary process: pre-deformation process, such as pressing the jaw, pressing the edge of the steel ingot, cutting the shoulder, etc.

Cov txheej txheem ua tiav: cov txheej txheem ntawm kev txo cov qhov tsis xws luag saum npoo av, xws li tshem tawm qhov tsis sib xws thiab cov duab ntawm kev ua kom pom tseeb.

Hom tau zoo:

(1) Qhov kev zam txim yooj yim yog qhov zoo heev, nws tuaj yeem tsim cov khoom me me tsawg dua 100kg. Thiab nws kuj tseem tuaj yeem tsim cov tawv hnyav ntev txog 300t.

(2) Cov cuab yeej siv yog cov cuab yeej dav dav dav dav.

(3) Txoj kev sib haum ntawm kev tsis nco qab yog kom maj mam deform qhov seem hauv thaj chaw sib txawv. Yog li ntawd, cov tonnage ntawm forging cov cuab yeej yuav tsum tau ua rau tib qho forging yog ntau me dua li ntawm kev tuag forging.

(4) cov kev xav tau tsawg rau cov khoom siv.

(5) Lub voj voog ntau lawm yog luv.

Qhov tsis zoo:

(1) Cov kev ua haujlwm ntau dua yog qhov qis dua li ntawm kev tuag forging.

(2) Kev quav ntsej muag muaj cov duab yooj yim, tsis muaj qhov tseeb ntawm qhov tseeb, thiab cov chaw ntxhib.

(3) Cov neeg ua haujlwm muaj kev siv zog siab thiab yuav tsum muaj qib siab.

(4) Nws tsis yooj yim rau kev paub mechanizate thiab Automation.

2. Tuag Forging

Tuag forging hais txog kev lom zem txoj kev nyob rau hauv uas forgings tau los ntawm kev sib sau cov lus tsis zoo nrog tuag ntawm kev tuag forging khoom siv. Cov ntaub ntawv sau cia tsim los ntawm cov qauv no yog qhov tseeb hauv qhov loj me, me me hauv kev siv machining pub, nyuaj rau hauv cov qauv, thiab siab hauv kev tsim khoom.

Tso cai raws li cov khoom siv: Tuag Forging ntawm Rauj, tuag forging rau crank xovxwm, tuag forging xovxwm, thiab lwm yam.

Qhov Zoo:

(1) siab dua kev ua tau zoo. Thaum lub sij hawm tuag zam, qhov deformation ntawm cov hlau yog nqa tawm hauv cov tuag kab noj hniav, yog li qhov xav tau tuaj yeem tau txais sai sai.

(2) Kev quav ntsej muag nrog cov duab nyuaj tuaj yeem raug muab cuam tshuam.

(3) Nws tuaj yeem ua rau cov dej ntws hluav taws xob ntxiv kom muaj dua tshiab thiab txhim kho cov kev pabcuam lub neej ntawm qhov chaw.

(4) Qhov loj ntawm kev tuag

(5) Txuag hlau cov ntaub ntawv thiab txo cov haujlwm ua haujlwm.

(6) nyob rau hauv cov xwm txheej ntawm cov khoom lag luam txaus, tus nqi ntawm qhov feem yuav raug txo kom tsawg.

Qhov tsis zoo:

(1) Qhov hnyav ntawm kev tuag Forgings yog txwv los ntawm kev muaj peev xwm ntawm kev tuag tuag khoom siv, feem ntau yog hauv qab 7 kg.

(2) Lub voj voog tsim khoom ntawm forging tuag yog ntev thiab tus nqi yog siab.

(3) Cov nqi peev ntawm kev tuag Forging cov khoom siv yog loj dua li ntawm kev zam dawb.

3. Yob Forging

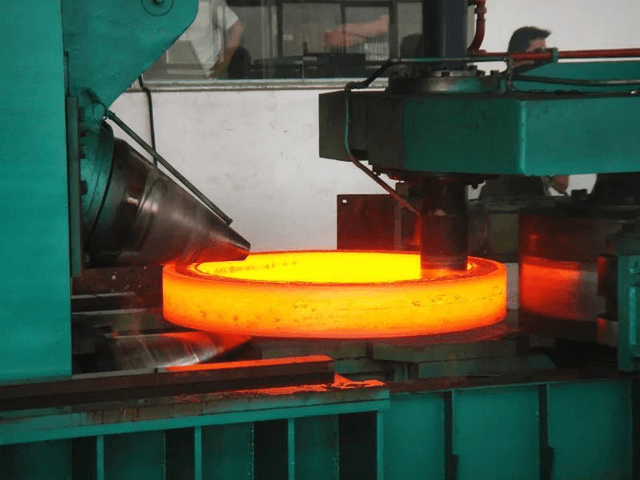

Dov forging hais txog cov txheej txheem forging nyob rau hauv uas ib khub ntawm cov kiv cua kev ntxuam-puab tuag tau txais cov nyiaj sau cia kom tau txais kev xav tau lossis tso cai.

Dov forging deformation yog ib qho nyuaj ntawm peb-seem deformation. Feem ntau ntawm cov khoom deformed ntws raws qhov kev taw qhia ntev kom nce lub nqi ntawm billet, thiab ib feem me me ntawm cov khoom ntws tom qab nce qhov dav ntawm lub billet. Thaum lub sij hawm yob forging txheej txheem, tus ntoo khaub lig-ntu ntawm lub pob nyiaj hli txo kom tsis tu ncua. Tus txheej txheem Forging siv lub hauv paus ntsiab lus ntawm kev yob txoj kev ua kom maj mam ua kom tsis muaj qab.

Dov forging yog tsim nyog rau deformation cov txheej txheem xws li elongating Shafts, dov slabs, thiab faib cov ntaub ntawv raws qhov ntev. Dov Forging tuaj yeem siv los tsim cov pas nrig sib txuas, cov nqaj hlau, cov kab, hooes, hoes thiab turbine hniav, thiab lwm yam.

Piv nrog dog dig tuag forging, yob forging muaj qhov zoo ntawm cov qauv khoom siv yooj yim, muaj suab nrov, yooj yim automation ua tau zoo.

4. Lub log tuag forging

Lub log tuag tuag yog ib txoj kev zam txim uas tau txais kev zam txim pub dawb kom ua ib qho dawb paug, thiab tom qab ntawd sau nws hauv cov log tsheb mould. Nws yog kev zam txim txoj kev ntawm kev tso cai pub dawb thiab tuag forging. Nws yog dav siv hauv cov khoom lag luam me thiab nruab nrab nrog tsawg dua kev tuag forging cov khoom thiab feem ntau yog kev zam rauj.

Muaj ntau hom log tsheb tau siv hauv cov log tsheb forging forging, thiab cov siv tau siv nyob rau hauv kev tsim khoom yog hom uas pwm, teeb pwm, cushion pwm, thiab lwm yam.

Lub kaw lub tog raj kheej kev tuag yog feem ntau siv rau kev forging forging forgings. Piv txwv li, lub zog nrog cov thawj coj ntawm ob qho xaus qee zaum siv rau kev zam txim tsis tau zam txim. Kaw Lub Tog Raj Kheej Tuag Yog Flash-Dawb Forging.

Rau Lub Log Khoom Mould Forgings nrog cov duab ua nyuaj, nws yog ib qho tsim nyog yuav ntxiv ob ib nrab pwm (uas yog, ntxiv ib feem ntawm lub tog raj kheej pwm los ua ke lub tog raj kheej pwm kom ua ke Thiab qhov dawb paug yog tsim nyob rau hauv cov kab noj hniav sib xyaw ntawm ob ib nrab pwm.

Cov yeeb yaj kiab sib xyaw yog feem ntau muaj ntawm ob ntu, cov pwm sab saud thiab qis dua. Txhawm rau kom phim rau sab sauv thiab qis dua tuag thiab tiv thaiv kev zam txim los ntawm kev hloov pauv, cov lus qhia pins thiab qhia feem ntau siv rau kev ua haujlwm. Tuag clamping yog feem ntau siv los tsim cov tsis tau zam txim nrog cov duab nyuaj, xws li txuas cov pas nrig, rab rawg tsis quav ntsej, thiab lwm yam.

Piv nrog pub dawb forging, lub log tuag forging muaj cov txiaj ntsig hauv qab no:

(1) Txij li thaum seem yog tsim nyob rau hauv kev tuag kab noj hniav, qhov loj ntawm kev forging yog qhov tseeb yog qhov tseeb thiab yog tus kuj zoo.

(2) Kev faib tawm cov kwj degerly yog tsim nyog, yog li qhov zoo yog siab.

(3) Lub log tuag forging tuaj yeem tso cai zam tau nrog cov duab sib txawv. Txij li cov duab ntawm kev Forging yog tswj los ntawm cov tuag kab noj hniav, seem yog tsim nrawm. Thiab cov khoom lag luam yog 1 txog 5 zaug siab dua li cov kev pub dawb.

(4) Muaj ob peb lub blocks, yog li cov khoom siv tau me me. Qhov no tsis tsuas yog txuag cov khoom hlau tab sis kuj txo cov tshuab mev-teev.

Qhov tsis zoo:

(1) Ib qho Forging rauj nrog lub tonnage loj dua;

(2) Tsuas yog kev zam txim me me tuaj yeem tsim tawm;

(3) Cov kev pabcuam lub neej ntawm cov log tsheb pwm yog tsawg;

(4) Feem ntau nws yog feem ntau yuav tsum cia siab rau Manpower txav lub log tsheb pwm thaum ua haujlwm, yog li kev siv zog yog qhov tseem ceeb;

(5) Cov log tsheb tuag tsis zoo yog siv los tsim cov khoom nruab nrab thiab me me ntawm kev lom zem.

Zhengxi yog ib tug paub zooForging Tshuab Chaw Tsim Tshuaj Hauv Suav, muab ntau hom kev lom zem presses, suav nrog kev zam dawb, tuag forging machine,Kub Forging Machine, khaub noom forging tshuab, thiab sov forging tshuab, thiab lwm yam Yog tias koj muaj kev xav tau, thov hu rau peb.

Lub sij hawm Post: Jun-30-2023