Forging yog lub npe sib sau rau Forging thiab Stamping. Nws yog ib txoj kev ua qauv uas siv rab rauj, thaiv, thiab xuas nrig ntawm kev ua kom zoo nkauj kom tau txais cov qauv ntawm cov duab uas xav tau thiab loj.

Dab tsi yog forging

Thaum lub sij hawm forging txheej txheem, tag nrho cov khoob undergoes tseem ceeb yas deformation thiab tus nqi loj ntawm cov roj yas loj. Hauv cov txheej txheem stamping, qhov seem yog tsim los ntawm kev hloov pauv txoj haujlwm ntawm txhua ntu thaj chaw, thiab tsis muaj cov dej yas ntws hla dhau nws. Forging yog tsuas yog siv los ua cov hlau seem. Nws kuj tseem tuaj yeem siv los ua cov txheej txheem uas tsis yog hlau, xws li engineering cov plastics, cov roj hmab, cib, thiab txoj kev sib sau ntawm cov khoom siv sib xyaw.

Dov, kos duab, thiab lwm yam hauv Forging thiab Metallurgical Kev lag luam yog tag nrho cov yas lossis ua tiav. Txawm li cas los xij, kev zam txim feem ntau yog siv los tsim cov khoom hlau, thaum nqus thiab kos duab hlau, ib daim hlab, khoom siv roj av, thiab xov hlau, thiab xaim.

Kev faib tawm ntawm kev zam txim

Forging yog tsuas yog ua raws li kev tsim qauv thiab deformation kub. Raws li kev sib haum qauv, Forging tuaj yeem muab faib ua ob pawg: Forging thiab Stamping. Raws li cov deformation kub, forging tuaj yeem muab faib ua kub, txias zam txim, thiab yog forgingmaling forging, thiab lwm yam.

1. Kub Forging

Kev Forging kub yog Forging ua tau saum cov recrystallization kub ntawm cov hlau. Ua kom qhov kub tau tuaj yeem txhim kho cov vacatity ntawm cov hlau, uas tau txais txiaj ntsig los txhim kho cov kev ua haujlwm zoo nkauj thiab ua rau nws tsis tshua tawg. Kev kub siab kub kuj tuaj yeem txo cov deformation tiv thaiv ntawm cov hlau thiab txo cov tonnage ntawm yuav tsum tauForging MachineryCov. Txawm li cas los xij, muaj ntau cov txheej txheem forging kub, qhov ua haujlwm precision yog neeg pluag, thiab cov nplaim tsis du. Thiab kev tsis lees paub txog kev xav txog oxidation, decarburization, thiab hlawv kev puas tsuaj. Thaum lub workpiece loj thiab tuab, cov khoom muaj lub zog muaj zog thiab cov khoom siv tuab dua, thiab lwm yam) yog siv.

Feem ntau siv kub forging kub yog: carbon steel 800 ~ 1250 ℃; Alloy qauv hlau 850 ~ 1150 ℃; Kev kub ceev steel 900 ~ 1100 ℃; Feem ntau siv txhuas alloy 380 ~ 500 ℃; Alloy 850 ~ 1000 ℃; Brass 700 ~ 900 ℃.

2. Txias forging

COOKING FORREEN yog Forging tau ua hauv qab cov hlau recrystallization kub. Feem ntau hais lus, txias zam txim yog hais txog kev lom zem ntawm chav sov.

Cov neeg ua haujlwm tsim los ntawm kev zam txim ntawm chav sov muaj qhov tseeb thiab qhov sib npaug, du cov txheej txheem, thiab yooj yim rau kev siv tshuab. Ntau qhov txias rau cov kab mob sib tsoo thiab cov khoom sib tsoo txias tuaj yeem siv ncaj qha raws li ntu lossis cov khoom tsis muaj kev xav tau machining. Txawm li cas los xij, thaum lub sij hawm forging txias, vim tias cov hlau tsis muaj zog ntawm cov hlau, tawg yog yooj yim rau thaum muaj kev tiv thaiv loj, xav tau loj-tonnage forging machinery.

3. Sov Forging

Forging ntawm qhov kub siab dua li qub kub tab sis tsis dhau lub recrystallization kub hu ua sov forging. Cov hlau yog preheated, thiab cua sov kub yog qhov qis dua li ntawm kev lom zem kub. Sov forging muaj qhov ntsuas siab dua, ib qho chaw smoother, thiab qis deformation tiv taus.

4. KhelowMal Forging

Isothermal forging cia kom muaj qhov ntsuas kub tsis tu ncua thaum tsim txheej txheem tag nrho. Isothermal Forging yog ua kom tag nrho cov kev siv ntau ntawm qee cov hlau ntawm tib qho kub lossis kom tau txais cov qauv tshwj xeeb thiab cov khoom tshwj xeeb. Kev zam txim rau kev zam yuav tsum khaws cov pwm thiab cov khoom tsis zoo ntawm qhov kub tsis tu ncua, xws li siv rau kev ua haujlwm tshwj xeeb, xws li Supplastic tsim.

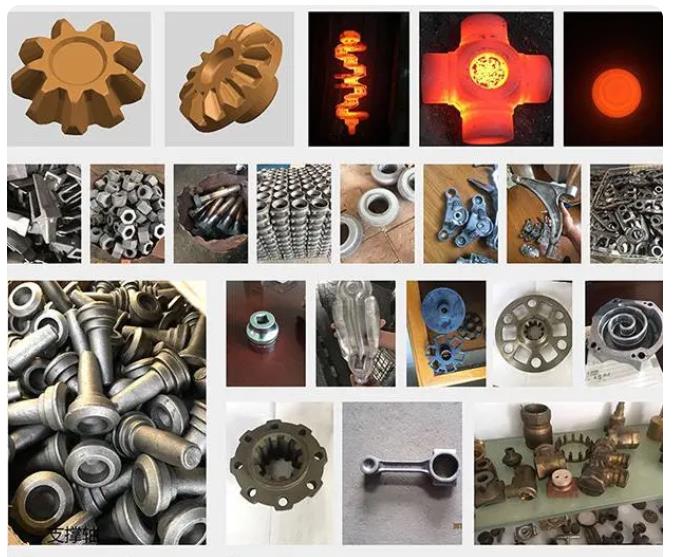

Cov yam ntxwv ntawm Forging

Forging tuaj yeem hloov cov qauv hlau thiab txhim kho cov khoom siv hlau. Tom qab ingot yog kub forged, tus thawj looseness, pores, micro-nrum, thiab lwm yam hauv lub xeev pov yog kev sib xyaw lossis welded. Tus thawj dendrites tau tawg, ua cov nplej pleev cov nplauv. Nyob rau tib lub sijhawm, tus thawj carbide cais tawm thiab tsis sib luag tau hloov. Ua kom cov qauv sib txawv, kom tau txais kev zam txim uas tau hnov qab, hnav ris tsho, muaj qhov ua tau zoo, thiab muaj kev ntseeg siab tag nrho hauv kev siv. Tom qab kev zam txim yog deformed los ntawm kub forging, cov hlau muaj cov qauv fibrous. Tom qab caning forging deformation, cov hlau crystal ua kom tiav.

Forging yog ua kom cov hlau ntws plastically los ua ib tug workpiece ntawm qhov xav tau. Qhov ntim ntawm hlau tsis hloov tom qab cov dej ntws roj hmab ntxiv vim yog lub zog sab nraud, thiab hlau ib txwm ntws mus rau ib feem nrog qhov tsis kam tawm tsam. Hauv kev tsim khoom, cov duab ntawm cov haujlwm ua haujlwm feem ntau tswj hwm raws li cov cai no kom ua tiav kev tawm dag zog xws li thickening, nthuav dav, thiab sib sib zog nqus daim duab.

Qhov loj me ntawm forged workpiece yog qhov tseeb thiab yog qhov tseem ceeb los teeb tsa pawg ntau lawm. Qhov ntev ntawm cov pwm ua ke hauv cov ntawv thov xws li forging, extrusion, thiab stamping yog qhov tseeb thiab ruaj khov. High-efficievievievy forging machinery thiab tsis siv neeg Forging cov kab ntau lawm yuav siv tau los npaj tshwj xeeb loj lossis pawg ntau lawm.

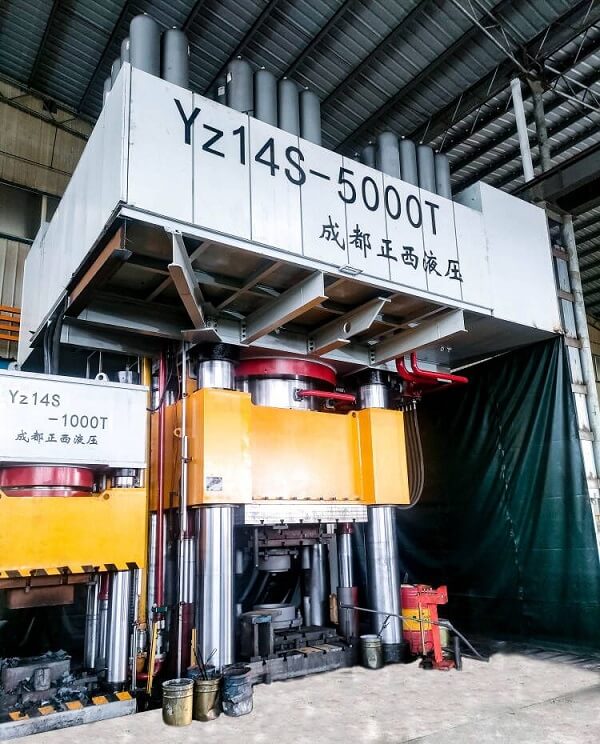

Feem ntau siv forging machinery suav nrog felding hammers,Hydraulic Presses, thiab tshuab tsom iav. Cov rauj rauj muaj kev cuam tshuam loj heev, uas tau txais txiaj ntsig rau cov yas ntws ntawm cov hlau, tab sis nws yuav tsim kev co. Cov xovxwm nias hydraulic siv cov khoom noj khoom zoo li qub, uas tau txais txiaj ntsig zoo los ntawm cov hlau thiab txhim kho cov qauv. Cov hauj lwm yog ruaj khov, tab sis cov khoom lag luam yog tsawg. Lub tshuab ua xovxwm muaj cov hlab ntsha ruaj thiab yog qhov yooj yim los siv kev ua tshuab thiab kev siv tshuab.

Kev loj hlob qauv ntawm Forging Technology

1) txhawm rau txhawm rau txhim kho qhov tsis zoo ntawm forged seem, feem ntau yog txhawm rau txhim kho lawv cov khoom siv neeg (lub zog, muaj zog, muaj zog, muaj zog.

Qhov no yuav tsum tau txais kev thov zoo dua ntawm kev xav ntawm cov hlau nplaum ntawm cov hlau. Siv cov ntaub ntawv nrog inherently zoo dua qub, xws li cov tshuab kho cov hlau thiab cov nqus hlau-meled-meled. Nqa tawm cov cua sov ua ntej thiab kev lom zem kom sov kom raug. Ntau nruj thiab nruj kev sim ua kom muaj kev cuam tshuam ntawm forged ntu.

2) Txuas ntxiv txhim kho kom haum rau kev zam txim thiab cov thev naus laus zis stamping. Cov kev ntsuas tsis yog txiav yog qhov kev ntsuas tseem ceeb tshaj plaws thiab kev coj ua rau kev lag luam Machinery los txhim kho cov khoom siv siv, txhim kho kev ua haujlwm ua haujlwm, txhim kho kev ua haujlwm. Kev loj hlob ntawm cov khoom cua sov oxidatative forging, nrog rau kev kho kom zoo, yuav zoo rau cov qauv kev kho mob, yuav muaj txiaj ntsig zoo, yuav muaj txiaj ntsig zoo rau cov ntaub ntawv tso cai ntawm kev lees paub thiab precision stamping.

3) Tsim cov khoom siv Forging thiab Forging cov kab ntau lawm nrog kev tsim khoom dua thiab automation. Nyob rau hauv tshwj xeeb ntau lawm, kev ua haujlwm tsim tau yog kev txhim kho thiab cov nqi forging tau txo.

4) Tsim cov ntawv sau cia ua kom haum rau cov tshuab (thov cov cuab yeej thev naus laus zis, kev tuag sai sai, thiab lwm yam). Qhov no ua rau ntau hom, me-batch forging ntau lawm los siv cov khoom siv ua kom zoo thiab cov khoom siv dag zog lossis cov kab ntau lawm. Ua kom nws cov khoom lag luam thiab kev lag luam nyab xeeb rau theem ntawm ntau lawm.

5) Tsim cov ntaub ntawv tshiab, xws li kev zam kev ua cov txheej txheem ntawm cov hmoov metallurgy (tshwj xeeb yog cov khoom siv ua kua, fiber ntau cov ntaub ntawv sib xyaw. Tsim txhim kho cov thev naus laus zis xws li superplastic tsim, muaj zog txoj kev sib sau, thiab kev hlub siab hauv siab.

Lub sijhawm Post: Feb-04-2024