Ngwá ntụ ntụ na-eme hydraulic Press

Ekelite

1) Etu bụ nke 40cr na 45 # steel site na ịgbaghara, tụgharịa na ezigbo egwe na-egosi na ị ga-ezuru ya. Ntuziaka elu elu ndị gbasoro iche iche iche iche iche iche iche iche site na mbata na abé, dị ka onye na-ezi ọla kọpa. Ya na cr.

2. Themụ nwanyị a na-edobe na ndebiri na-adịghị mma, ma na-arụsi ọrụ ike na-ese n'elu mmiri ma na-eme ka mkpuchi mmiri na-ese n'elu mmiri na-eme na usoro ịpị. Ahọpụtara, "ntụ ntụ", na-ese n'elu mmiri, nrụgide na-egbochi igbu oge, nrụgide ahụ efe efe mgbe ị na-aga. Mgbe ị na-ebugharị ntụ ntụ, elu na ala na-ese n'elu mmiri na-ese n'elu mmiri na-ese n'elu mmiri na-acha odo odo.

3) usoro mbepu nwere mkpochapu ma na-echebe ihe maka nhọrọ; Nwanyị na-ebugharịkwa na ụmụ nwanyị na-eme ka ọ bụrụ nke a na-adọkpụ onwe ha na ụmụ nwanyị na-agbadata ka ị hapụ ebu ahụ, na mwepụ nke ụmụ nwanyị na-aba uru iji chebe ngwaahịa a site na iji ike gwụ ngwa.

4) Inye nri dị elu, na-atụkwa elu ọnọdụ na ọnọdụ igwe na-enweghị isi iji chọpụta ọnọdụ na plc usoro njikwa ziri ezi, yana usoro eji arụ ọrụ.

5) A na-etinye ihe ndị na-abụghị mita na nkwonkwo n'etiti efere na-ese n'elu efere na ihe mgbochi nke ajị anụ ahụ na akwa mkpuchi na-enweghị atụ, na akụkụ ahụ niile adịghị na kọmpụta anụ ahụ.

Usoro inye nri

1. Esimme nri ga-enwe olile-nri 6, na Hopper ọ bụla ga-ebubata akụrụngwa dị iche iche.

2. Enwere ike itinye Holdper, nwee ezigbo akara.

3.Automatic nke akụrụngwa, ọ bụla 5-10 strok.

Enwere ike ịtọ ọnụọgụ arụmọrụ 4.Happer na HMI, 1,2,3 ... 10, na-arụkọ ọrụ ọnụ.

5.6 Nnukwu Sporthers ga-arụnyere n'elu igwe, ọ bụla Hopper ọ bụla nwere ike ibu dị 15 n'arọ nke ntụ ntụ.

Aba

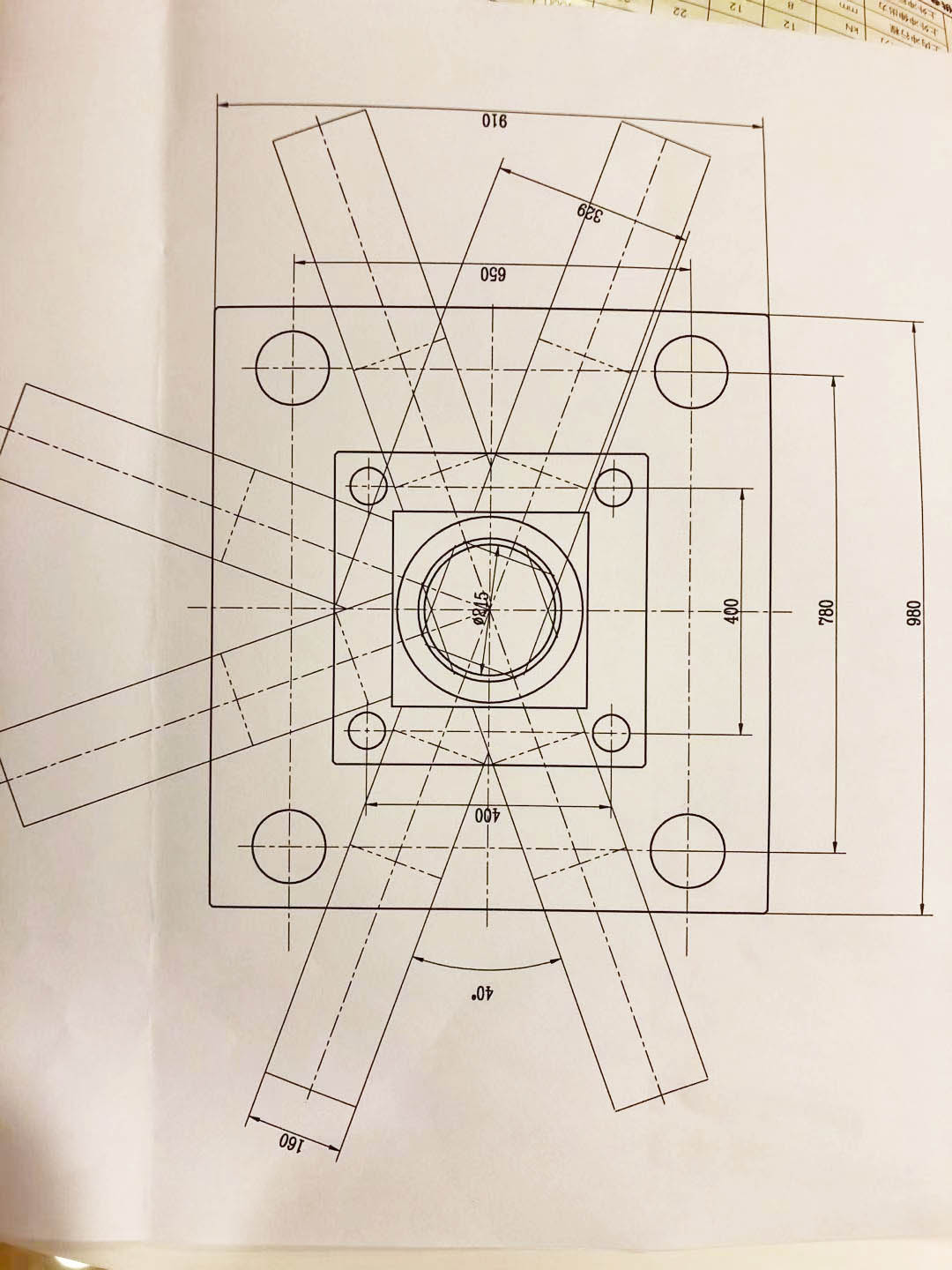

A ga-eme ya kọlụm (ogidi)C45 na-agbaghara ncharama nwee nnukwu Chrome mkpuchi ọkpụrụkpụ 0.08mm. Na-eme ọgwụgwọ na nke na-arụsi ọrụ ike.

Ichepụta ụkpụrụ

JB / T3818-99"Nka na ụzụ nke hydraulic Press"

Gb5226.1-2002"Nchekwa nke igwe-mechaical na ngwa eletriki 1: chọrọ teknuzu òkè"

GB / T 3766-2001"A choro oru ndi ozo maka usoro hydraulic"

GB17120-97"Pịa Ọrụ Nrụ Ọrụ Ọrụ"

Jb9967-99"Hydraulic igwe na-adịghị mma"

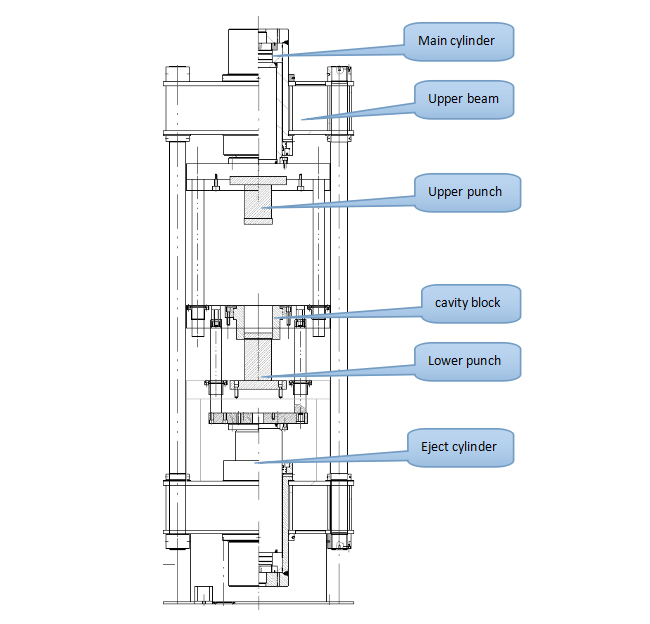

Isi ahụ

Ihe eji eji eji igwe eji eme ihe eji eme ihe eji eme ya na inyocha ihe ndi ozo. Ike na ime ihe ike nke akụrụngwa dị mma, ọdịdị dịkwa mma. Akụkụ ahụ niile nke igwe na-agbaze site na igwe eji eme ihe, nke ejiri carbon dioxide mee ihe iji hụ na ị na-akwalite ya.

Silinda

| Akụkụ | Fnri |

| Cylinder Barrel |

|

| Piston Rod |

|

| Akàrà | Na-eme ka ihe ngosi na-egosi akara |

| Pistin | Egosiputa ihe ejiji ọlaji, na-eyi ezigbo iyi, na-ejide oge ọ bụla nke cylinder |

Servo Sistem

1.Servo sistemụ

Desfonsages nke Service System

Ichekwa Ichekwa

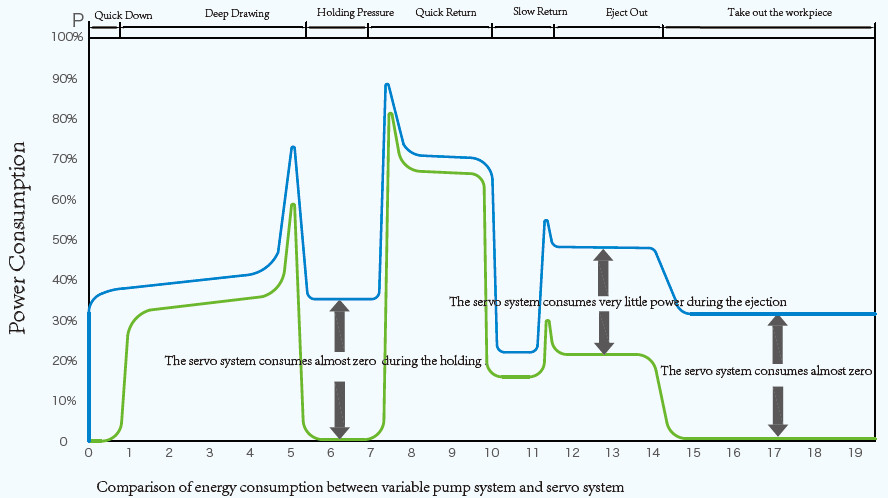

Jiri ya tụnyere usoro nrụpụta ọdịnala, sistemụ mmanụ na-ejikọta usoro iwu nke Services na-ejikọ onwe onye na-ejikọ mmanụ ọkụ, nke na-ewetara nnukwu nchekwa, na ikeIchekwa ọnụego nwere ike iru 30% -80%.

Oru oma

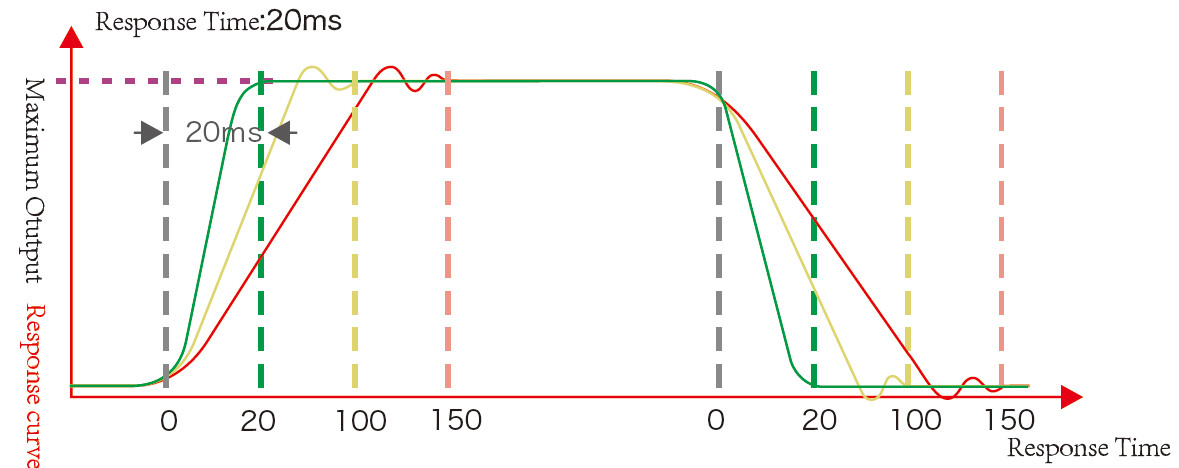

Ọsọ nzaghachi dị ngwa na oge nzaghachi dị obere 20ms, nke na-eme ka nzaghachi ọsọ nke hydraulic sistemụ.

Nkenke

Oke nkwughachi ngwa ngwa na-ekwe nkwa mmeghe na mmechi mmechi, ọnọdụ ziri ezi nwere ike iru 0.1mm, na ọnọdụ ọrụ pụrụ iche ga-aba uru± 0.01mm.

Usoro dị elu, m modulmm module na-eme ka nrụgide sistemụ kwụsiri ike na nsogbu na-erughị± 0,5, melite ogo ngwaahịa.

Nchedo gburugburu

NKE: Oke mkpọtụ nke hydraulic sistemụ bụ 15-20 db dị ala karịa nke mbụ na-agbanwe agbanwe.

Okpomoku: Mgbe eji usoro ihe eji eme ihe, mmanu mmanu a na - ewedata mmanu mmanu ahihia, nke na - eme ka ndu nke hydraulic akara ma ọ bụ na - ebelata ike nke ngwa nju oyi.

Ngwaọrụ

Nchekwa foto-eletrik na-eche nche n'ihu & n'azụ

Slide mkpọchi na TDC

Aka aka abụọ kwụrụ ọtọ

Cydraulic na-akwado mkpuchi mkpuchi

Nchedo karịrị akarị: valvụ nchekwa

Okwu mmiri dị larịị

Mụọ mmanụ

Akụkụ ọ bụla nwere ike na-eche nche

Nchekwa nchekwa

A na-enye mkpụrụ mkpọchi maka akụkụ

Ọrụ niile nke pịa nwere ọrụ nchekwa nchekwa, dịka onye na-enye ọpụpụ agaghị arụ ọrụ ọ gwụla ma nsogbu na-alaghachi na mbụ. Slide enweghị ike pịa mgbe onye na-enye iwu na-eweghachị na-apụta. Mgbe ịghasa esemokwu na-eme, mkpu na-egosi na ihuenyo mmetụ ahụ wee gosi ihe ọ bụ ọgụ ahụ.

Usoro hydraulic

A na-etinye tank nke ọma na-amanye usoro ịchafụ (igwe oyi

2. Kedu usoro hydraulic system na-achịkwa usoro nchịkwa na-agba ọsọ ọsọ na arụ ọrụ dị elu.

3. A na-emegharị tank mmanụ mmanụ nwere nzacha ikuku iji soro na mpụga na-eme ka a ghara ịhụ na mmanụ hydraucuc.

4. Njikọ dị n'etiti valve na mmanụ mmanụ na-ejikọ ọka na-agbanwe agbanwe iji gbochie ịbawanye agbaghasị mmanụ ọkụ ma dozie nsogbu nke obere mmanụ.