Ígwọ iyi dị omimi bụ usoro nke mpempe akwụkwọ ọla n'ime oghere.MmaEjiri ya n'ọtụtụ usoro mmepụta, dị ka ngwaahịa nke akụkụ ụgbọ ala, yana ngwaahịa ụlọ, dị ka kichin na-enweghị nsị.

Usoro a na-eri:Etu ego (dị oke elu), ọnụ ahịa (ọkara)

Ngwaahịa:Nri na nkwakọ ngwaahịa, nke tebụl na arịa, arịa, ụgbọ ala, ugbo ala, aerospicace, wdg.

Na-eme ka ọ dị mma:Kwesịrị ekwesị maka Mmepụta Mass

Àgwà:Nkenke nke ịkpụpụta elu dị oke mma, mana a ga-ezo aka nke a ga-ezo

Ọsọ:Oge ngwa ngwa n'otu n'otu, dabere na nkwanye ugwu na mkparita uka nke igwe

Ihe eji eme ihe

1 Ọla dị mma bụ: ọla kọpa, ọla kọpa, almunom alloy, na ọla ndị ọzọ dị mfe ịnya na draịlị

2. N'ihi na usoro ihe nke ọla na-emetụta arụmọrụ na arụmọrụ dị mma, a na-ejikarị akụrụngwa metre maka nhazi.

Ntụle echiche

1. A ga-achịkwa ahịrị nke akụkụ nke akụkụ nke akụkụ nke ihe osise dị n'etiti 5mm-500mm (0.2-16.69in).

2. Ogologo oge dị omimi dị omimi bụ ihe dị ka 5 ugboro n'ime dayameta nke akụkụ nke akụkụ.

3. Ogologo oge nke akụkụ nke akụkụ ahụ, nke na-eteta mpempe akwụkwọ. Ma ọ bụghị ya, a ga-agbasa n'elu oge nhazi n'ihi na ọkpụrụkpụ nke mpempe akwụkwọ ga-eji nwayọọ nwayọọ belata n'oge usoro ịgbatị.

Nzọụkwụ nke ịbịaru

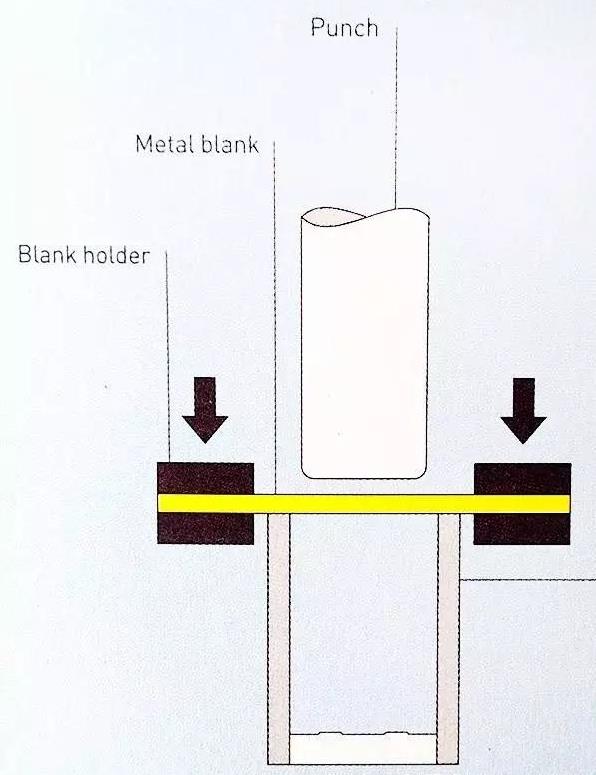

Kwụpụ 1: Mezie mpempe mpempe ọla na hydraulic Press

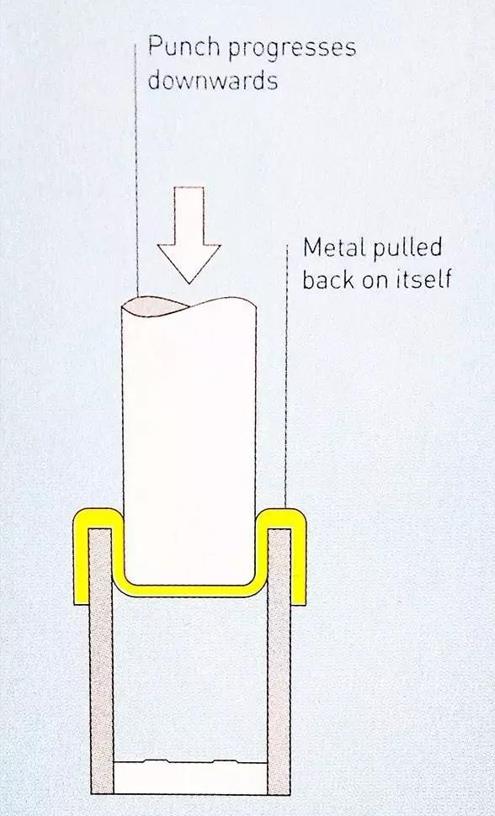

Kwụpụ 2: Nkume stampụ na-agbadata ma na-amịpụta mpempe ọla n'ime mgbe a ga-etinye mpempe akwụkwọ na mgbidi nke ebu.

Kwụpụ 3: Isi stampụ ahụ na-aga n'ihu na akụkụ ahụ emechara site na tebụl ala.

Ikpe ikpe

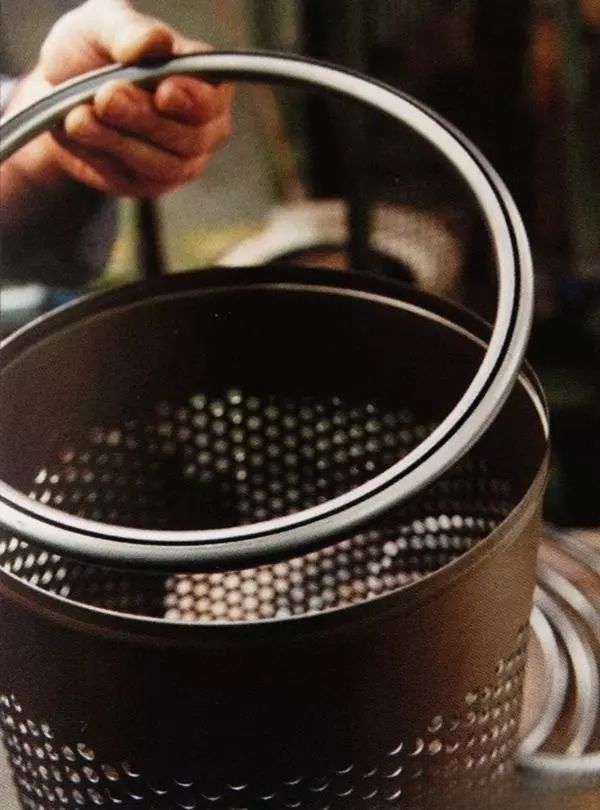

Usoro na-emepụta nke igwe nche

Kwụpụ 1: Bee ihe 0.8mm (0.031in) dị larịị carọn carbon n'ime ụdị achicha dị gburugburu.

Kwụpụ 2: Mezie ahihia carbon mpempe akwụkwọ na hydraulic Press (nke a na-edozi ya n'akụkụ clamps gburugburu ikpo okwu press hydraulic).

Kwụpụ 3: Ọkpụkpụ ahụ na-agbadata nwayọ, wepụta mpempe carbon n'ime ebu.

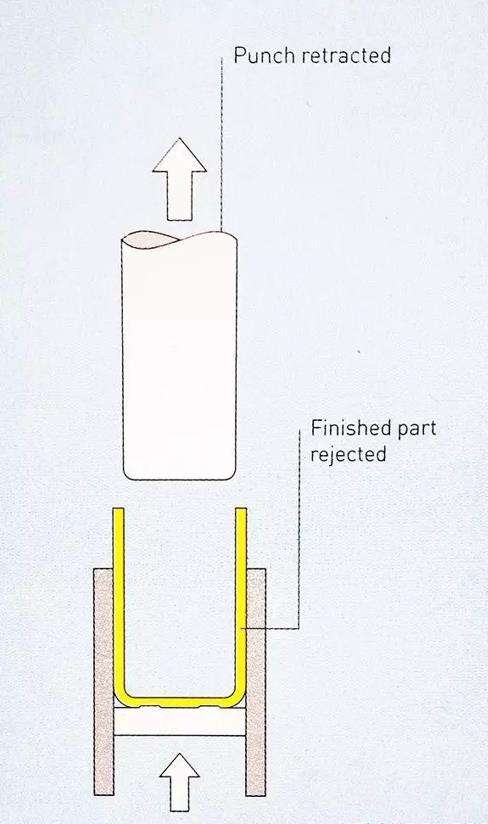

Kwụpụ 4: Isi stampụ ahụ na-ebili, na ndị na-akpụ akpụ akpụ akpụ akpụ akpụ.

Kwụpụ 5: Wepu

Kwụpụ 6: Polish

Ngwaahịa ndị ọzọ na-adọta

Oge Post: APR-13-2023