Nri na-akwụsị bụ mkpuchi mkpuchi na arịa nrụgide ahụ ma bụrụkwa ihe dị mkpa na-akpata nrụgide arịa. Ogo nke isi na-emetụta ogologo oge dị ogologo ma nwee ntụkwasị obi nke arịa ọrịa nrụgide. Ọ bụ akụrụngwa dị mkpa na akụrụngwa akụrụngwa na Petrochemicals, ike nke atọ, nri, ọgwụ na ọtụtụ ụlọ ọrụ ndị ọzọ.

N'ihe banyere udi, enwere ike ekewa isi n'ime isi nkpuchi, ndi isi na-eji efere, isi oval, na isi spret. Ndị isi arịa ndị na-ebili mmiri na-esitekarị na-eme ihe nkiri, a na-ejikarị ndị isi na-eme ihe na-eme ka ọ bụrụ nrụgide na n'elu. Naanị obere arịa ndị nwere obere nrụgide na-eji ndị isi diski dị ala.

1. Usoro nhazi nri

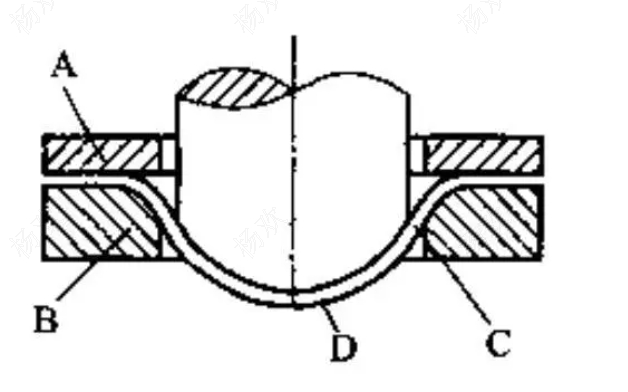

(1) staming. Iji gbanwee na mmepụta ọrụ, ịpị ndị isi dị egwu na obere dayameta chọrọ ọtụtụ akụkụ nke isi.

(2). Ọ dị mma maka isi ultra-buru ibu na nke Ultra. Karịsịa na ụlọ ọrụ kemịkalụ, nke na-emetụta oke arụmọrụ dị elu na nke dị ala, ọ dị mma karịchaa. Ndị isi oval dị ezigbo mma maka ịgbagharị, ebe a na-ejikarị isi nri na isi spred siri ike karị pịa.

2. A na-eji ngwa nri na ngwaọrụ

(1) akụrụngwa kpo oku: Achịcha gas. A na-eji ihe eji ekpo ọkụ dị ugbu a maka kpo oku, na mmanụ ọkụ na-eji ihe dị ka o kwere mee. N'ihi na a na-eji ya mara ọcha, arụmọrụ dị elu, njikwa okpomọkụ dị mfe, na ihe isi ike na-efe efe na decarburation. Ọkụ na-ekpo ọkụ ga-enwe ike iji ya na-eji ihe na-eji ihe na-eji ihe na-eji

.

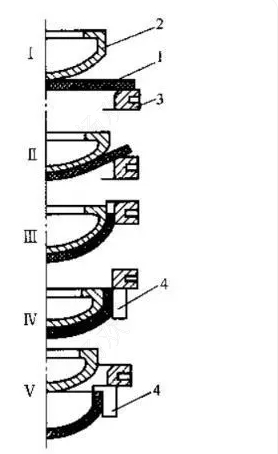

(2)Na-akwụsị. Enwere ụdị abụọ: otu ọrụ na okpukpu abụọ.

Otu ihe pụtara naanị cylinder na-enweghị ntụpọ na enweghị cylinder na-egbu egbu. Naanị obere na nke na-ejikọ ihe na-eji ya. Nnukwu ihe niile na-eji eme ihe okpukpu abụọ, ya bụ, enwere cylinder njide efu na cylinder na-akwụghị ọtọ.

Onye mbufe nke hydraulic pịa bụ mmiri. Ọ dị ọnụ ala, na-akpali ngwa ngwa, enweghị ike, ọ nweghịkwa ihe dị elu akara dị ka igwe hydraulic. Arụmọrụ dị ala karịahydraulic pịa, na nduzi a anaghị agbasi mbọ ike. Mgbasa nke hydraulic Press kwụ chịm ma nwee ezigbo ihe achọrọ maka akara na nduzi.

(3) Jiri Ngwaọrụ, gụnyere ụdị dị iche iche nke isi na nke ala ma na-akwado, wdg.

3. Ihe ndị na-emetụta nnukwu mgbidi nke isi

Ọtụtụ ihe na-emetụta mgbanwe dị n'isi ọkpụrụkpụ, nke enwere ike ịchịkọta dị ka ndị a:

(1) Njirimara. Dịka ọmụmaatụ, oke nke onye isi akara aka dị ukwuu karịa nke isi akara carbon.

(2) ọdịdị isi. Isi nke nwere oghere nwere obere thinning, isi spret nwere oke nke thinning, na isi elliptical nwere ọkara.

(3) Oke ka ala na-anwụ na radius fillet, nke pere mpe.

(4) Oke oghere dị n'etiti di elu na nke dị ala, obere obere ntakịrị.

(5) Ọnọdụ lubric dị mma ma ọnụọgụ nke thinning dị obere.

(6) Okpomoku di elu na-ekpo ọkụ, ọnụ ọgụgụ nke thinning.

4. Pịa na ụdị the kegide

(1) Tupu a na-agbanye isi nke ọ bụla, a ga-ewepụ usoro oxide na oghere isi. Ekwesịrị itinye uri na ebu tupu stampụ.

(2) Mgbe ịpị, a ga-etinye isi ya dị ka akpa ahụ ka ọ bụrụ na enwere ike. Etiti etiti n'etiti oghere dị na obere ebu kwesịrị ịbụ ihe na-erughị 5mm. Mgbe ịpị akwa mkpuchi, kwesịrị ịkwụ ụgwọ ka ọ na-etinye oghere elliptical na oghere ahụ n'otu ụzọ ahụ ogologo oge nke ebu. N'oge usoro ịpị, buru ụzọ, mezie oghere ahụ na ọnọdụ mmeghe nke oghere ma na-apụta. Kpoo ya ruo n'isi obere elu karịa ụgbọ elu nke obere ebu (ihe dị ka 20mm), wee pịazie elu ya ọzọ. Olzọ ntụpọ na-adakwa n'otu oge iji pịa isi. N'oge ịpị, ike na-adọrọ adọrọ kwesịrị iji nwayọ na-abawanye site na obere iji buru ibu ma ghara ịbawanye ma ọ bụ belata na mberede.

(3) Isi na-ekpo ọkụ nwere ike ịdọpụ ya na ebu ma bulie ya mgbe ọ dabara n'okpuru 600 Celsius. Etinyekwala ya na vent. Emebila ihe karịrị iberibe abụọ n'elu ibe ha tupu ị jụ ime ụlọ. N'oge stampụ na-aga n'ihu, anwụ na-anwụ anwụ ruo ihe dịka 250 Celsius C na stating. Arụ ọrụ nwere ike ịga n'ihu mgbe a na-eme ka ajụdị belata iji belata okpomọkụ nke ịnwụ.

(4) Igwe okpu a ga-akpụzi n'otu nzọ ụkwụ ka o kwere mee. Mgbe ọ gaghị ekwe omume ịpụta n'otu oge n'ihi ihe mgbochi ọnọdụ, ekwesịrị ịkwụ ụgwọ na isi mgbe ị na-akụ ihe oghere ahụ ọkpụrụkpụ nke oghere.

5. Ọ na-ekpo ọkụ Press makaMing hydraulic Press

Ọ bụ ọsọ ọsọ ma na-agbanwe agbanwe na mpaghara ngwa, nwere ntụkwasị obi dị elu, na akụ na ụba na-aba uru.

■ Kwesịrị ekwesị maka isi okwu na-ekpo ọkụ.

Ihe owuwu akuko a na-agbadakwa ihe owuwu ulo.

■ Ihe mmịfe ahụ nwere ihe dị na-agagharị na-agagharị.

■ Ọrịa nke njide njide ihe na-enweghị mgbagha.

E nwere ike idozigharị ike na-agbatị na-enweghị ike.

■ nwere ike ịghọta otu ihe na ime ihe abuo n'otu n'otu.

6

■ Ọ dị mma maka isi okwu na-acha.

Ihe owuwu akuko a na-agbadakwa ihe owuwu ulo.

■ Ihe eji agbatị igwe nwere ebu, ebu nke dị mkpirikpi, ebe a na-anya, yana ngwa-ngwa ngwa.

E nwere ike idozigharị ike na-agbatị na-enweghị ike.

Oge Post: May-09-2024