The application of composite materials in the aerospace field has become an important engine for technological innovation and performance improvement. The application of composite materials in different aspects will be introduced in detail below and explained with specific examples.

1. Aircraft Structural Parts

In the aviation industry, composite materials are widely used in aircraft structural parts, such as fuselage, wings, and tail components. Composite materials enable lighter designs, reduce the weight of the aircraft itself, and improve fuel efficiency and range. For example, the Boeing 787 Dreamliner uses a large amount of carbon fiber reinforced composite materials (CFRP) to form key components such as the fuselage and wings. This makes the aircraft lighter than traditional aluminum alloy structure aircraft, with a longer range and lower fuel consumption.

2. Propulsion System

Composite materials are also widely used in propulsion systems such as rocket engines and jet engines. For example, the space shuttle’s exterior heat-shielding tiles are made from carbon composites to protect the aircraft’s structure from damage at extreme temperatures. In addition, jet engine turbine blades often use composite materials because they can withstand high temperatures and pressures while maintaining low weight.

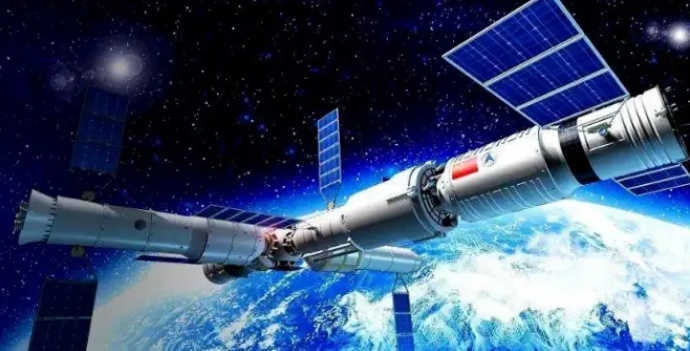

3. Satellites and Spacecraft

In the aerospace sector, composite materials play a key role in manufacturing structural parts for satellites and other spacecraft. Components such as spacecraft shells, brackets, antennas, and solar panels can all be made of composite materials. For example, the structure of communication satellites often uses composite materials to ensure sufficient stiffness and lightweight design, thereby reducing launch costs and increasing payload capacity.

4. Thermal Protection System

The spacecraft needs to deal with extremely high temperatures when re-entering the atmosphere, which requires a thermal protection system to protect the spacecraft from damage. Composite materials are ideal for building these systems because of their excellent resistance to heat and corrosion. For example, the space shuttle’s heat shielding tiles and insulation coatings are often made from carbon composites to protect the aircraft structure from high-temperature heat.

5. Materials Research and Development

In addition to applications, the aerospace field is also constantly researching and developing new composite materials to meet the needs of higher performance and more complex environments in the future. These studies include the development of new fiber-reinforced materials, resin matrices, and improved manufacturing processes. For example, in recent years, the focus of research on carbon fiber composite materials in the aerospace field has gradually shifted from improving strength and stiffness to improving heat resistance, fatigue resistance, and oxidation resistance.

To sum up, the application of composite materials in the aerospace field is not only reflected in specific products but also in the continuous pursuit, research, and development of new materials and technologies. These applications and research jointly promote the development of aerospace technology and provide strong support for human exploration of space and the improvement of air transportation.

Zhengxi is a professional hydraulic press manufacturing company and can provide high-quality composite material molding machines to press those composite materials.

Post time: Apr-09-2024