With the continuous development and progress of the automobile industry, automobile manufacturers are constantly striving to find innovative production methods and technologies in order to improve production efficiency and product quality. The automated car roof production line is one of the major technological innovations that has brought huge benefits to car manufacturers. This article will introduce the working principle, advantages, and impact on the automobile manufacturing industry of the car roof automatic production line produced by Chengdu Zhengxi Hydraulic.

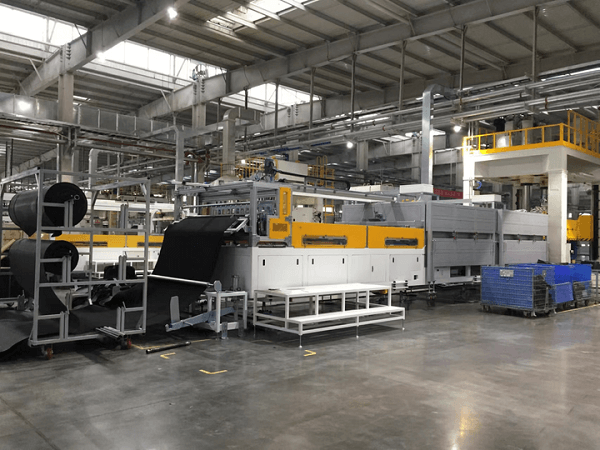

The automobile roof automated production line is a highly automated production system that can complete the production process of automobile roofs in a short time. The production line consists of car interior hydraulic presses, multiple automatic machines, and robots that automatically perform the cutting, forming, welding, and painting processes of the ceiling. Computer technology controls the entire production line operation process to ensure the accuracy and efficiency of the production process.

Composition of Car Roof Automatic Production Line

Automobile roof automated production lines usually consist of multiple parts and equipment. The following is the general production process and required equipment:

1. Material handling:

1) Material cutting machine: used to cut raw materials (such as steel plates, and aluminum plates) into required shapes and sizes.

2) Material conveyor belt: transports the cut material to the next work stage.

2. Forming and welding:

1) Forming machine: An automotive interior hydraulic press is used to press material into the basic shape of the headliner. Multi-axis robots can be used for precise operations.

2) Welding robot: performs the welding process to ensure that the roof components are structurally sound.

3. Painting:

1) Paint sprayer: Automated painting equipment used to apply the desired color and protective layer.

2) Paint baking room: used to dry sprayed paint to ensure the quality of the coating.

4. Assembly:

1) Assembly line: Assembling individual components together, including skylights, glass, support structures, etc.

2) Robotic assembly cells: used to perform precise assembly operations, ensuring correct positioning and connection of components.

5. Quality control:

1) Vision inspection systems: used to detect defects, color consistency, and assembly correctness.

2) Sensors: Monitor the size, shape, and mass characteristics of ceiling components.

3) Automation control system: Responsible for coordinating the work of various equipment, correcting problems, and recording production data.

6. Packaging and shipping:

1) Packaging equipment: Pack the produced canopy components into appropriate packaging to ensure safety during transportation and storage.

2) Conveyor system: delivers packaged roof components to the shipping area, ready for shipment to automobile manufacturers or other customers.

Advantages of Automobile Roof Automated Production Line

The car roof automatic production line produced by Chengdu Zhengxi Hydraulic has significant advantages. Its main advantage is that it significantly increases productivity. Compared with traditional manual production methods, the use of automated production lines can manufacture ceilings more efficiently and shorten the production cycle.

Secondly, automated production lines can increase the stability and consistency of product quality. Since the entire process is performed by machines and robots, the impact of human factors on product quality can be avoided, thereby improving product stability and consistency. In addition, automated production lines can also reduce labor costs and labor requirements, thereby reducing costs.

Impact of Car Roof Automatic Production Line

Automobile roof automated production lines play a huge role in the automobile manufacturing industry. It promotes the improvement and transformation of automobile manufacturing products. The traditional manual production model can no longer meet the requirements of automobile manufacturers for production efficiency and product quality, so they have to introduce automated production lines to improve production efficiency and product quality.

Secondly, the introduction of automated production lines has promoted the digital and intelligent development of the automobile manufacturing industry. The operation process of automated production lines is controlled by computer systems and requires a large amount of data and algorithm support, which allows automakers to strengthen the research and development of digital technology and smart equipment.

To sum up, the car roof automatic production line is an important innovation in the automobile manufacturing industry. It can improve production efficiency and product quality, and promote product upgrading and transformation in the automotive manufacturing industry. Despite some challenges, the introduction of automated car roof production lines has had a positive impact on the automotive manufacturing industry.

As a professional hydraulic press factory in China, Zhengxi provides car interior hydraulic presses for pressing car roofs. At the same time, we can also provide our customers with completed automobile roof automated production line solutions. If you have any needs, please contact us.

Post time: Oct-27-2023