The development of the key basic material industry has an important impact on the implementation of the “Made in China 2025″ strategy. In terms of high-performance fibers, carbon fiber composite materials with the reputation of “black dollar” have gradually become the “top priority” in the emerging materials industry. In recent years, with the advancement of domestic carbon fiber independent production technology, the gap with the advanced level of developed countries has been narrowing, the application of carbon fiber composite products has also entered a rapid development track, and carbon fiber composite materials have been increasingly used In modern public transportation such as airplanes, automobiles, high-speed rail, light rail, etc.

Hydraulic presses play a great role in carbon fiber molding. Compared with traditional metal structures, the molded carbon fiber products have higher strength, stronger fatigue resistance and better corrosion resistance. At the same time, due to the low density of carbon fiber, it is 50% lighter than low-carbon steel and 30% lighter than magnesium/aluminum alloy structure.

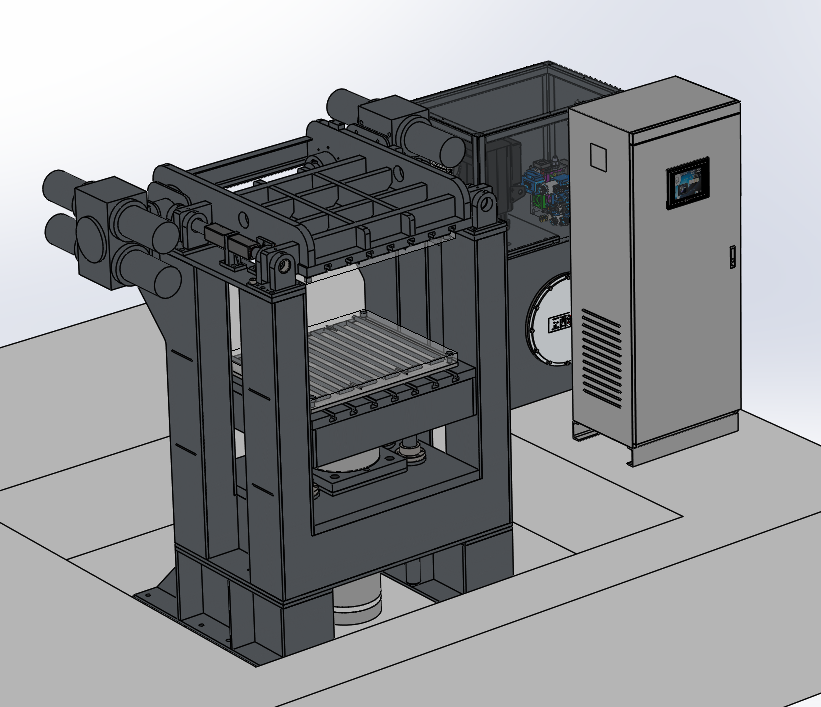

Carbon fiber compression molding hydraulic press refers to a machine that puts the pre-impregnated carbon fiber cloth into the compression mold, and then adjusts the pressure, temperature and time to make the desired carbon fiber product.

Carbon fiber compression molding hydraulic press steps:

1. Mold cleaning: clean the mold to avoid the residue of dust and debris.

2. Apply release agent: After the mold is clean and smooth, apply the release agent to prevent the product from sticking to the mold and not being taken out after molding.

3. Material preparation: prepare the required carbon fiber prepreg according to the shape and size of the product.

4. Stacking: stacking the carbon fiber prepreg layer by layer and pre-pressing it to form a dense solid with a regular shape and a certain quality.

5. Into the mold: Put the stacked raw materials into the carbon fiber compression molding four-column hydraulic press mold, close the mold, set the pressure, time, and temperature, and then press at high temperature.

6. Cooling and demoulding: Cool for a period of time after the hot pressing, and then open the mold to take out the product.

7. Post-processing: The product taken out from the carbon fiber compression molding four-column hydraulic press mold is relatively rough, and it has to go through a series of post-processing procedures such as trimming, polishing, and painting.

Ms.Serafina

Tel/Wts/Wechat: 008615102806197

Post time: Jul-27-2021