Metal deep drawing is the process of stamping metal sheets into hollow cylinders. Deep drawing is used in a wide range of production processes, such as in the production of car parts, as well as household products, such as stainless steel kitchen sinks.

Process cost: mold cost (extremely high), unit cost (medium)

Typical products: food and beverage packaging, tableware and kitchen utensils, furniture, lamps, vehicles, aerospace, etc.

Yield suitable: suitable for mass production

Quality: The precision of the molding surface is extremely high, but the specific surface quality of the mold should be referred to

Speed: Fast cycle time per piece, depending on the ductility and compression resistance of the metal

Applicable material

1. The deep drawing process depends on the balance of metal ductility and compression resistance. Suitable metals are: steel, copper, zinc, aluminum alloy, and other metals that are easy to tear and wrinkle during deep drawing

2. Because the ductility of metal directly affects the production efficiency and quality of deep drawing, metal flakes are generally used as raw materials for processing.

Design considerations

1. The internal diameter of the part section formed by deep drawing should be controlled between 5mm-500mm (0.2-16.69in).

2. The longitudinal length of deep drawing is at most 5 times the inner diameter of the part section.

3. The longer the longitudinal length of the part, the thicker the metal sheet. Otherwise, there will be surface tearing during processing because the thickness of the metal sheet will gradually decrease during the stretching process.

Steps of deep drawing

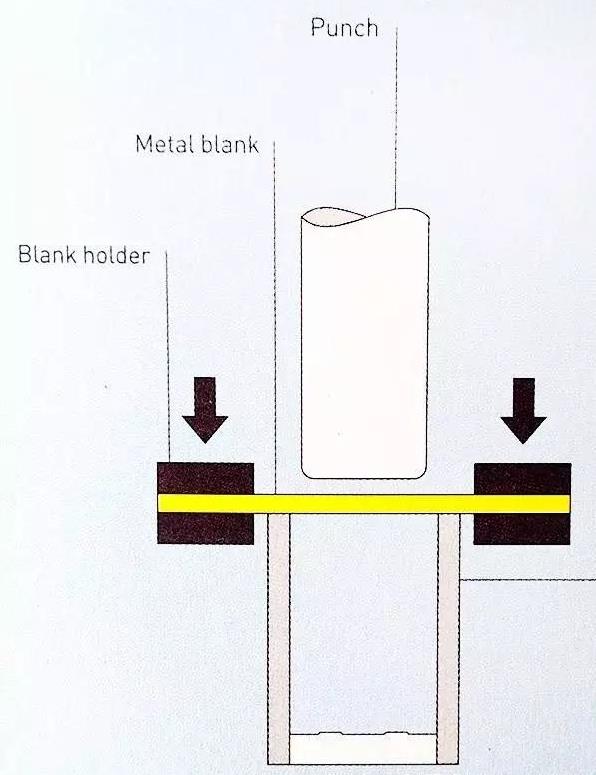

Step 1: Fix the cut metal sheet on the hydraulic press

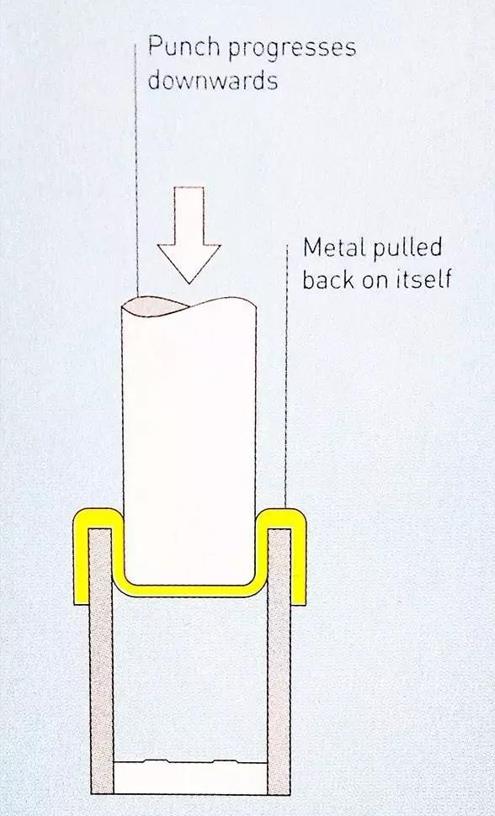

Step 2: The stamping head descends and squeezes the metal sheet into the mold until the metal sheet is completely attached to the inner wall of the mold.

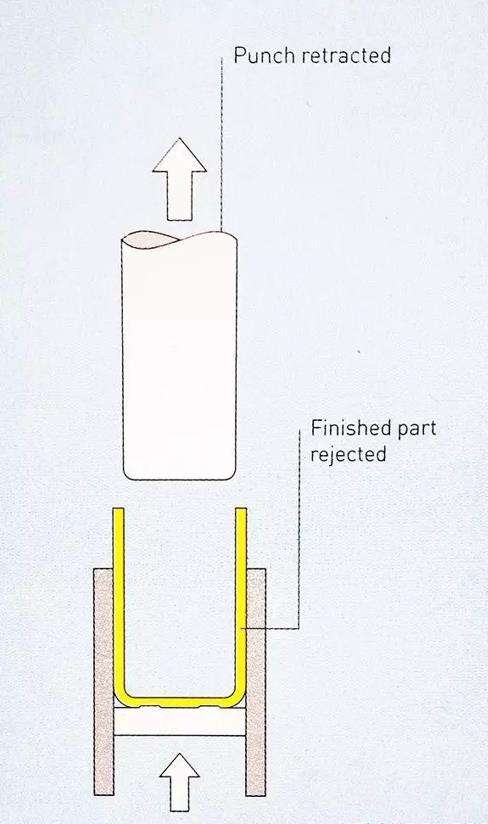

Step 3: The stamping head goes up and the finished part is ejected by the bottom table.

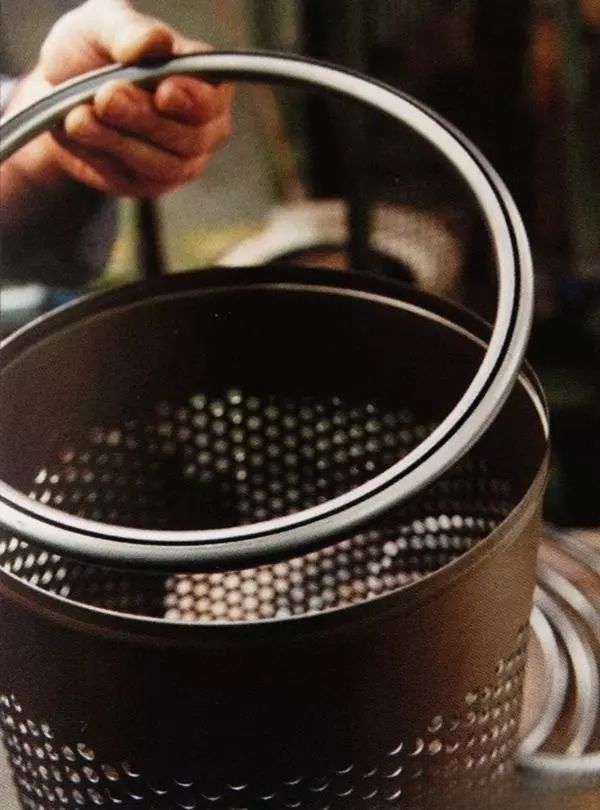

Actual case

The manufacturing process of metal umbrella bucket

Step 1: Cut the 0.8mm (0.031in) thick carbon steel plate into a round cake shape.

Step 2: Fix the cut carbon steel sheet on the hydraulic press (fixed by clamps around the hydraulic press platform).

Step 3: The stamping head descends slowly, extruding the carbon steel sheet into the mold.

Step 4: The stamping head rises, and the formed metal cylinder is ejected.

Step 5: Trimming

Step 6: Polish

Other deep drawn metal products

Post time: Apr-13-2023