With the rapid development of advanced composite material technology and process technology, the application proportion of composite materials in aerospace equipment has steadily increased, and the application parts have expanded from non-load-bearing and sub-load-bearing structures to main load-bearing and core components.

The development of composite materials requires comprehensive consideration of weight reduction, performance, and cost. It has fatigue resistance, corrosion resistance, high strength, and high rigidity. It is also an ideal material for current market needs.

Products made of resin, carbon fiber and additives obviously have the above comprehensive performance, but the current market is more traditional hand-made, hand-laid, hand-made and other crafts are more resistant to labor and are not easy to pass on.

At present and for a period of time in the future, on the basis of appropriately retaining traditional manual manufacturing, high-efficiency, automation, and low-cost manufacturing technologies for high-performance composite materials such as high temperature resistance, corrosion resistance, and high strength are the main directions of composite material development.

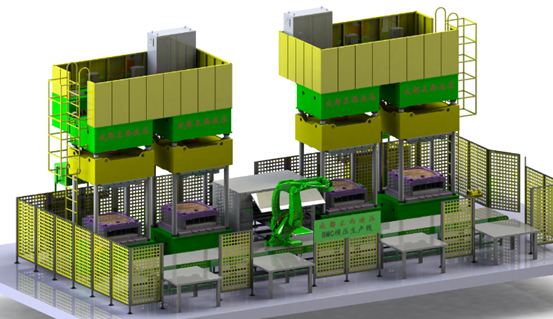

In the composite material industry, Chengdu Zhengxi Hydraulic Equipment Manufacturing Co., Ltd. has developed the latest SMC composite material full-automatic compression molding production line, BMC composite material full-automatic compression molding production line, and GMT composite material full-automatic compression molding production line. This production line has achieved a reduction Artificially stable production demand has been widely promoted.

Post time: May-04-2021