Cold forging and hot forging are two important processes common in the field of metal forging. They have significant differences in material plasticity, temperature conditions, microstructure, and application range. In this article, we will discuss in detail the characteristics of these two processes, as well as the application of cold and hot forging machines in actual production.

The difference between cold forging and hot forging

Cold forging refers to the forging process carried out at room temperature, and the temperature of the metal workpiece is lower than the recrystallization temperature. Due to the poor plasticity of materials at low temperatures, cold forging usually requires a large force to carry out plastic deformation. Therefore, cold forging is suitable for alloy materials with higher strength. Hot forging is a forging process carried out under high-temperature conditions, and the temperature of the metal workpiece is higher than the recrystallization temperature. At high temperatures, metal has good plasticity, so hot forging needs to apply less force, which is suitable for various types of metal materials.

The temperature difference between cold forging and hot forging has a significant effect on the microstructure of the material. During cold forging, metal grains are not prone to recrystallization, so the morphology of the original grains is usually retained after cold forging. In the hot forging process, the metal grains are easy to recrystallize at high temperatures, so a more uniform and finer grain structure is usually obtained after hot forging. Therefore, hot forging can improve the toughness and plasticity of materials.

In addition, cold forging and hot forging have different ranges in practical application. Cold forging is mainly used to manufacture alloy workpieces with high strength and low plasticity, such as high-strength steel. Because cold forging requires the application of large forces, it is generally used to manufacture small and relatively simple-shaped workpieces. Hot forging is suitable for most metal materials. It can manufacture workpieces with complex shapes and can improve the toughness and plasticity of materials. It is widely used in the manufacture of large industrial equipment such as auto parts, aerospace parts, and engineering machinery.

Cold forging machine and hot forging machine

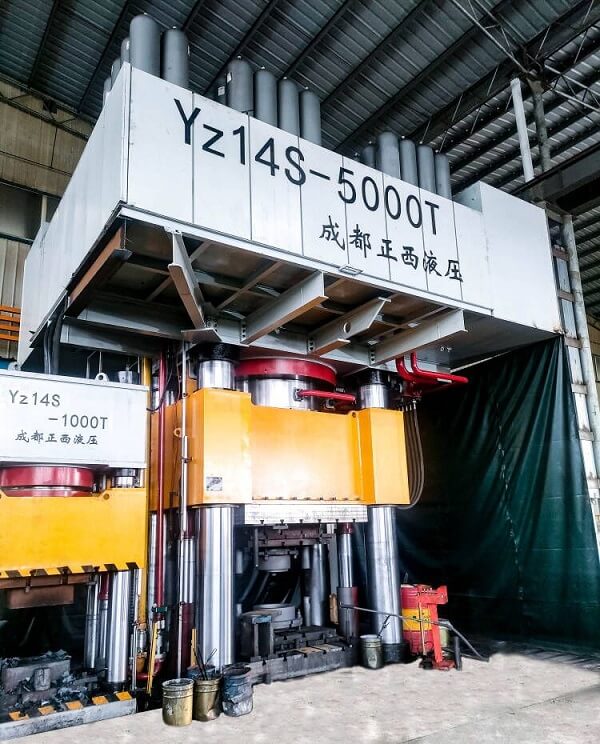

A cold forging machine is a special equipment for cold forging process, its main feature is that it can carry out metal forging at room temperature. Cold forging machines generally include hydraulic cold forging machines and mechanical cold forging machines. The hydraulic cold forging machine drives the forging process through the hydraulic system, which has a large forging force and flexibility and can be used to manufacture workpieces of various sizes. The mechanical cold forging machine realizes the forging process through mechanical transmission. Compared with the hydraulic cold forging machine, its forging force is smaller, but it has advantages in some specific applications.

The hot forging machine is the special equipment for the hot forging process and can carry out metal forging under high-temperature conditions. It usually adopts hydraulic or mechanical transmission. And different types of machines are selected according to the required forging force and process requirements. The hot forging press heats the metal workpiece above the recrystallization temperature to make it reach good plasticity and then applies appropriate force to complete the forging process.

In actual production, both cold forging machines and hot forging machines play an important role. The cold forging machine is suitable for alloy materials with lower plasticity requirements and higher strength requirements. It is usually used to manufacture smaller-sized workpieces, such as bolts, nuts, etc. The hot forging machine is suitable for metal materials that have high requirements on material plasticity and need to improve toughness and plasticity. It can manufacture large-sized and complex-shaped workpieces, such as automobile crankshafts and aero-engine parts.

To sum up, cold forging and hot forging are two common processes in metal forging. And they have significant differences in temperature, material plasticity, microstructure, and application range. Cold forging is suitable for alloy materials with high strength and low plasticity, while hot forging is suitable for various types of metals, especially those that need to improve toughness and plasticity. Cold forging machines and hot forging machines are special equipment used to realize these two processes. They play an important role in the field of metal processing, providing high-quality metal parts for various industries.

Zhengxi is a well-known manufacturer of forging presses in China, providing high-quality cold forging machines and hot forging machines. If you have any needs, please contact us immediately. Our technicians will provide you with perfect hydraulic press solutions.

Post time: Aug-04-2023