The dish end is the end cover on the pressure vessel and is the main pressure-bearing component of the pressure vessel. The quality of the head is directly related to the long-term safe and reliable operation of the pressure vessel. It is an indispensable and important component in pressure vessel equipment in petrochemicals, atomic energy, food, pharmaceuticals, and many other industries.

In terms of shape, the heads can be divided into flat heads, dish-shaped heads, oval heads, and spherical heads. The heads of high-pressure vessels and boilers are mostly spherical, and oval heads are mostly used for medium pressure and above. Only a small number of low-pressure vessels use disc-shaped heads.

1. Dish-end Processing Method

(1) Stamping. To adapt to mass production, pressing thick-walled and small-diameter heads requires multiple sets of head molds.

(2) Spin. It is suitable for ultra-large and ultra-thin heads. Especially in the chemical industry, which mostly involves large-scale and low-volume operations, it is particularly suitable for spinning. Oval heads are very suitable for spinning, while dish heads are rarely used and spherical heads are more difficult to press.

2. Dish Head Processing Equipment and Tools

(1) Heating equipment: gas stove. Reflective heating furnaces are currently used for heating, and oil or gas heating is used as much as possible. Because it is characterized by clean combustion, high efficiency, easy temperature control, and difficulty in overburning and decarburization. The heating furnace should be equipped with a temperature-measuring device and a temperature recorder

.

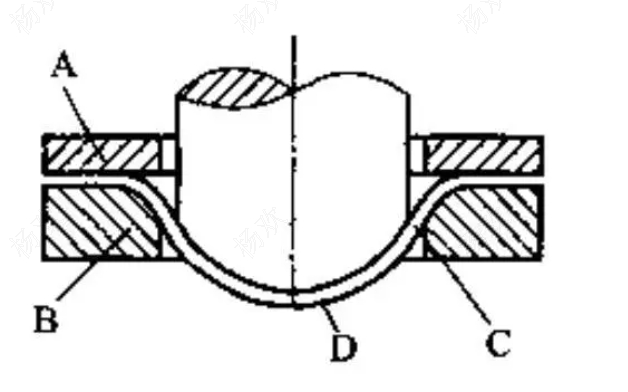

(2) Dish end press. There are two types: single-action and double-action.

Single action means only a stamping cylinder and no blank holder cylinder. Only small and medium-sized factories use it. Large factories all use double action, that is, there is a blank holder cylinder and a stamping cylinder.

The transmission medium of the hydraulic press is water. It is cheap, moves quickly, is not stable, and does not have as high sealing requirements as hydraulic machines. The efficiency is lower than the hydraulic press, and the guidance requirements are not strict. The transmission of the hydraulic press is stable and has high requirements for sealing and guidance.

(3) Use tools, including various types of head-forming upper and lower molds and supports, etc.

3. Factors Affecting the Thick Wall of the Head

Many factors affect the change in head thickness, which can be summarized as follows:

(1) Material properties. For example, the thinning amount of lead seal head is much greater than that of carbon seal head.

(2) Head shape. The disc-shaped head has the smallest amount of thinning, the spherical head has the largest amount of thinning, and the elliptical head has a medium amount.

(3) The larger the lower die fillet radius, the smaller the thinning amount.

(4) The larger the gap between the upper and lower dies, the smaller the thinning amount.

(5) The lubrication condition is good and the amount of thinning is small.

(6) The higher the heating temperature, the greater the amount of thinning.

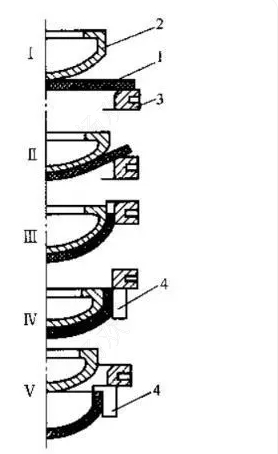

4. Press and Form the Dish End

(1) Before each head is pressed, the oxide scale on the head blank must be removed. Lubricant should be applied to the mold before stamping.

(2) When pressing, the head blank should be placed as concentrically with the mold as possible. The center deviation between the blank and the lower mold should be less than 5mm. When pressing a holed head, attention should be paid to placing the elliptical opening on the blank in the same direction as the long and short axes of the mold. During the pressing process, first, align the hole punch with the opening position of the blank and push out. Push it to a point slightly higher than the plane of the lower mold (about 20mm), then press the upper mold down again. The hole punch also falls at the same time to press the head into shape. During pressing, the punching force needs to be slowly increased from small to large and should not be increased or decreased suddenly.

(3) The hot stamping head can only be dragged away from the mold and lifted when it cools to below 600°C. Do not place it in a vent. Do not stack more than two pieces on top of each other before cooling to room temperature. During continuous stamping, the die temperature rises to about 250°C and stamping should not be continued. Work can only continue after cooling measures are taken to reduce the temperature of the die.

(4) The holed head should be formed in one step as much as possible. When it is impossible to form at one time due to conditional constraints, attention should be paid to the concentricity with the head when punching the hole, and attention should be paid to maintaining uniform wall thickness at the flange of the hole.

5. Hot Press Head Forming Hydraulic Press

It is fast and flexible in application range, has high production reliability, and is economical and applicable.

■ Suitable for hot press head forming.

■ The press structure adopts the four-column structure.

■ The holder slider is equipped with a radially moving adapter.

■ The stroke of the blank holder cylinder is adjustable.

■ The blank holder force and stretching force can be adjusted automatically.

■ Can realize single action and double action respectively.

6. Cold Press Head Forming Hydraulic Press

■ Suitable for cold press head forming.

■ The press structure adopts the four-column structure.

■ The stretching machine is equipped with an upper mold, lower mold, mold connection, and quick-change device.

■ The blank holder force and stretching force can be adjusted automatically.

Post time: May-09-2024