1. Free forging

Free forging refers to the processing method of using simple general-purpose tools or directly applying an external force to the blank between the upper and lower anvils of the forging equipment to deform the blank to obtain forgings with the required geometric shape and internal quality.

Free forging mainly produces forgings in small batches. Forging equipment such as forging hammers and hydraulic presses are used to form blanks to obtain qualified forgings. Free forging adopts the hot forging method.

The free forging process includes a basic process, an auxiliary process, and a finishing process.

The basic process of free forging is upsetting, drawing, punching, bending, cutting, twisting, shifting and forging, etc. But the three most commonly used processes in actual production are upsetting, drawing, and punching.

Auxiliary process: pre-deformation process, such as pressing the jaw, pressing the edge of the steel ingot, cutting the shoulder, etc.

Finishing process: the process of reducing the surface defects of forgings, such as removing the unevenness and shaping of the forging surface.

Advantage:

(1) The forging flexibility is great, it can produce small pieces of less than 100kg. And it can also produce heavy pieces up to 300t.

(2) The tools used are simple general-purpose tools.

(3) The forming of forgings is to gradually deform the blank in different regions. Therefore, the tonnage of forging equipment required to forge the same forging is much smaller than that of die forging.

(4) Low precision requirements for equipment.

(5) The production cycle is short.

Disadvantages:

(1) The production efficiency is much lower than that of die forging.

(2) Forgings have simple shapes, low dimensional accuracy, and rough surfaces.

(3) Workers have high labor intensity and require high technical levels.

(4) It is not easy to realize mechanization and automation.

2. Die forging

Die forging refers to the forging method in which forgings are obtained by forming blanks with dies on special die forging equipment. The forgings produced by this method are precise in size, small in machining allowance, complex in structure, and high in productivity.

Classified according to the equipment used: die forging on the hammer, die forging on the crank press, die forging on the flat forging machine, die forging on the friction press, etc.

Advantages:

(1) Higher production efficiency. During die forging, the deformation of the metal is carried out in the die cavity, so the desired shape can be obtained quickly.

(2) Forgings with complex shapes can be forged.

(3) It can make the metal streamline distribution more reasonable and improve the service life of parts.

(4) The size of the die forging is more accurate, the surface quality is better, and the machining allowance is smaller.

(5) Save metal materials and reduce cutting workload.

(6) Under the condition of sufficient batches, the cost of parts can be reduced.

Disadvantages:

(1) The weight of die forgings is limited by the capacity of general die forging equipment, mostly below 7 kg.

(2) The manufacturing cycle of the forging die is long and the cost is high.

(3) The investment cost of die forging equipment is larger than that of free forging press.

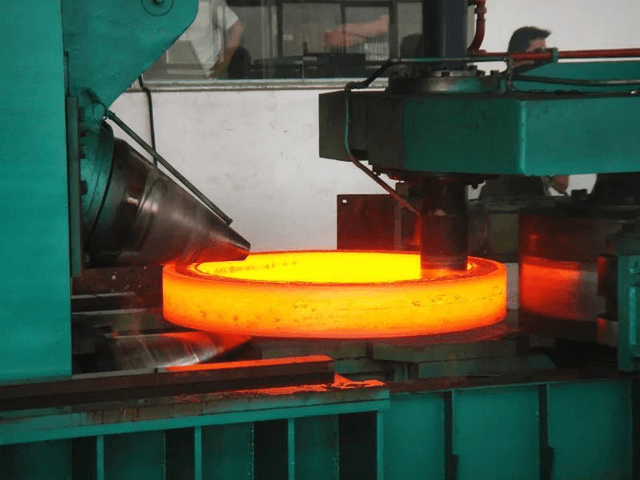

3. Roll forging

Roll forging refers to a forging process in which a pair of counter-rotating fan-shaped dies are used to plastically deform the billet to obtain the desired forging or forging billet.

Roll forging deformation is a complex three-dimensional deformation. Most of the deformed material flows along the length direction to increase the length of the billet, and a small part of the material flows laterally to increase the width of the billet. During the roll forging process, the cross-sectional area of the billet root decreases continuously. The roll forging process uses the principle of roll forming to gradually deform a blank.

Roll forging is suitable for deformation processes such as elongating shafts, rolling slabs, and distributing materials along the length direction. Roll forging can be used to produce connecting rods, twist drill bits, wrenches, road spikes, hoes, picks and turbine blades, etc.

Compared with ordinary die forging, roll forging has the advantages of simple equipment structure, stable production, low vibration and noise, easy automation, and high production efficiency.

4. Tire die forging

Tire die forging is a forging method that adopts the free forging method to make a blank, and then forms it in the tire mold. It is a forging method between free forging and die forging. It is widely used in small and medium-sized enterprises with less die forging equipment and most of them are free forging hammers.

There are many types of tire molds used in tire mold forging, and the commonly used ones in production are type drop, buckle mold, set mold, cushion mold, clamping mold, etc.

The closed cylinder die is mostly used for the forging of rotary forgings. For example, gears with bosses on both ends are sometimes used for forging non-revolving forgings. Closed cylinder die forging is flash-free forging.

For tire mold forgings with complex shapes, it is necessary to add two half molds (that is, add a parting surface) in the cylinder mold to make a combined cylinder mold. And the blank is formed in the cavity composed of two half molds.

The composite film is usually composed of two parts, the upper and lower molds. In order to match the upper and lower dies and prevent the forgings from shifting, guide posts and guide pins are often used for positioning. Die clamping is mostly used to produce non-revolving forgings with complex shapes, such as connecting rods, fork forgings, etc.

Compared with free forging, tire die forging has the following advantages:

(1) Since the blank is formed in the die cavity, the size of the forging is relatively accurate and the surface is relatively smooth.

(2) The distribution of streamline tissue is reasonable, so the quality is high.

(3) Tire die forging can forge forgings with relatively complex shapes. Since the shape of the forging is controlled by the die cavity, the blank is formed quickly. And the productivity is 1 to 5 times higher than that of free forging.

(4) There are few remaining blocks, so the machining allowance is small. This not only saves metal material but also reduces machining man-hours.

Disadvantages:

(1) A forging hammer with a larger tonnage is required;

(2) Only small forgings can be produced;

(3) The service life of the tire mold is low;

(4) It is generally necessary to rely on manpower to move the tire mold during work, so the labor intensity is relatively high;

(5) Tire die forging is used to produce medium and small batches of forgings.

Zhengxi is a well-known forging machine manufacturer in China, providing various types of forging presses, including free forging machines, die forging machines, hot forging machines, cold forging machines, and warm forging machines, etc. If you have any needs, please contact us.

Post time: Jun-30-2023