Blacksmithing is an ancient and important metalworking method that dates back to 2000 BC. It works by heating a metal blank to a certain temperature and then using pressure to shape it into the desired shape. It is a common method for manufacturing high-strength, high-durability parts. In the forging process, there are two common methods, namely free forging and die forging. This article will explore the differences, advantages and disadvantages, and applications of these two methods.

Free Forging

Free forging, also known as free hammer forging or the free forging process, is a method of metal forging without a mold. In the free forging process, a forging blank (usually a metal block or rod) is heated to a temperature where it becomes plastic enough and then shaped into the desired shape using equipment such as a forging hammer or forging press. This process relies on the skills of operating workers, who need to control shape and size by observing and mastering the forging process.

Advantages of free forging:

1. Flexibility: Free forging is suitable for workpieces of various shapes and sizes because there is no need to make complex molds.

2. Material saving: Since there is no mold, no additional materials are needed to make the mold, which can reduce waste.

3. Suitable for small batch production: Free forging is suitable for small batch production because mass production of molds is not required.

Disadvantages of free forging:

1. Reliance on workers’ skills: The quality of free forging depends on workers’ skills and experience, so the requirements for workers are higher.

2. Slow production speed: Compared with die forging, the production speed of free forging is slow.

3. Shape and size control is difficult: Without the assistance of molds, shape and size control in free forging is difficult and requires more subsequent processing.

Free forging applications:

Free forging is common in the following areas:

1. Manufacturing various types of metal parts such as forgings, hammer parts, and castings.

2. Produce high-strength and high-durability mechanical parts such as crankshafts, connecting rods, and bearings.

3. Casting key components of heavy machinery and engineering equipment.

Die Forging

Die forging is a process that uses dies to forge metal. In this process, a metal blank is placed in a specially designed mold and then shaped into the desired shape through pressure. Molds can be single or multi-part, depending on the complexity of the part.

Advantages of die forging:

1. High precision: Die forging can provide highly precise shape and size control, reducing the need for subsequent processing.

2. High output: Since the mold can be used multiple times, mold forging is suitable for mass production and improves production efficiency.

3. Good consistency: Die forging can ensure the consistency of each part and reduce variability.

Disadvantages of die forging:

1. High production cost: The cost of making complex molds is relatively high, especially for small batch production, which is not cost-effective.

2. Not suitable for special shapes: For very complex or non-standard-shaped parts, expensive custom molds may need to be made.

3. Not suitable for low-temperature forging: Die forging usually requires higher temperatures and is not suitable for parts requiring low-temperature forging.

Applications of die forging:

Die forging is widely used in the following fields:

1. Production of automotive parts such as engine crankshafts, brake discs, and wheel hubs.

2. Manufacturing key parts for the aerospace sector, such as aircraft fuselages, engine parts, and flight control components.

3. Produce high-precision engineering parts such as bearings, gears and racks.

In general, free forging and die forging each have their own advantages and limitations and are suitable for different production needs. Choosing the appropriate forging method depends on the complexity of the part, the production volume, and the required accuracy. In practical applications, these factors often need to be weighed to determine the optimal forging process. The continued development and improvement of forging processes will continue to drive the application areas of both methods.

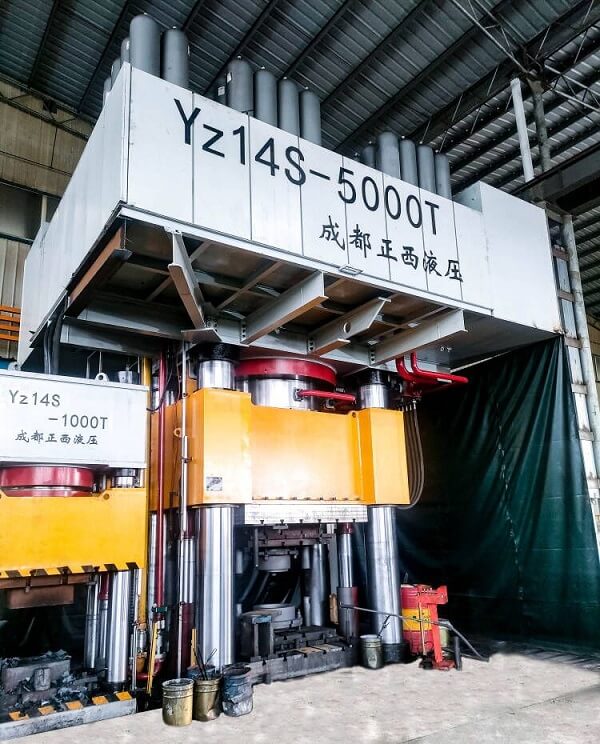

Zhengxi is a professional forging press factory in China, providing high-quality free forging presses and die forging presses. In addition, hydraulic presses can also be customized and produced according to customer needs. If you have any needs, please contact us.

Post time: Sep-09-2023