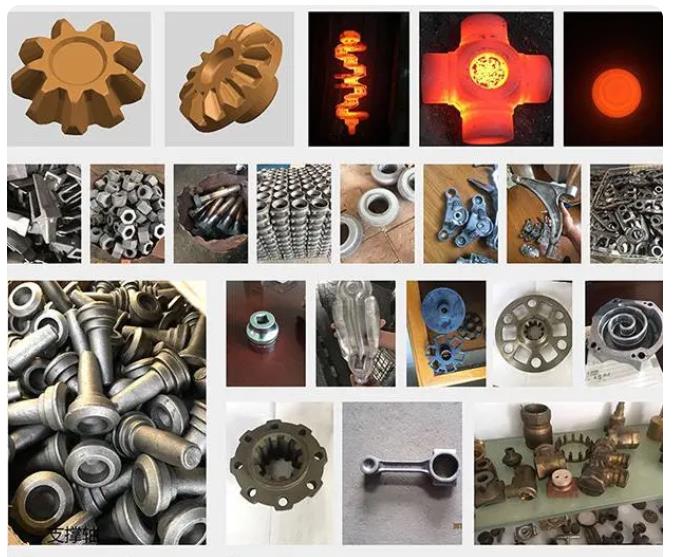

Forging is the collective name for forging and stamping. It is a forming processing method that uses the hammer, anvil, and punch of a forging machine or a mold to exert pressure on the blank to cause plastic deformation to obtain parts of the required shape and size.

What is forging

During the forging process, the entire blank undergoes significant plastic deformation and a relatively large amount of plastic flow. In the stamping process, the blank is mainly formed by changing the spatial position of each part area, and there is no plastic flow over a large distance inside it. Forging is mainly used to process metal parts. It can also be used to process certain non-metals, such as engineering plastics, rubber, ceramic blanks, bricks, and the forming of composite materials.

Rolling, drawing, etc. in forging and metallurgical industries are all plastic or pressure processing. However, forging is mainly used to produce metal parts, while rolling and drawing are mainly used to produce general-purpose metal materials such as plates, strips, pipes, profiles, and wires.

Classification of Forging

Forging is mainly classified according to forming method and deformation temperature. According to the forming method, forging can be divided into two categories: forging and stamping. According to the deformation temperature, forging can be divided into hot forging, cold forging, warm forging, and isothermal forging, etc.

1. Hot forging

Hot forging is forging performed above the recrystallization temperature of the metal. Increasing the temperature can improve the plasticity of the metal, which is beneficial to improving the intrinsic quality of the workpiece and making it less likely to crack. High temperatures can also reduce the deformation resistance of metal and reduce the tonnage of required forging machinery. However, there are many hot forging processes, the workpiece precision is poor, and the surface is not smooth. And the forgings are prone to oxidation, decarburization, and burning damage. When the workpiece is large and thick, the material has high strength and low plasticity (such as roll bending of extra thick plates, drawing of high carbon steel rods, etc.), and hot forging is used.

Generally used hot forging temperatures are: carbon steel 800~1250℃; alloy structural steel 850~1150℃; high speed steel 900~1100℃; commonly used aluminum alloy 380~500℃; alloy 850~1000℃; brass 700~ 900℃.

2. Cold forging

Cold forging is forging performed below the metal’s recrystallization temperature. Generally speaking, cold forging refers to forging at room temperature.

Workpieces formed by cold forging at room temperature have high shape and dimensional accuracy, smooth surfaces, few processing steps, and are convenient for automated production. Many cold forged and cold stamped parts can be directly used as parts or products without the need for machining. However, during cold forging, due to the low plasticity of the metal, cracking is easy to occur during deformation and the deformation resistance is large, requiring large-tonnage forging machinery.

3. Warm forging

Forging at a temperature higher than normal temperature but not exceeding the recrystallization temperature is called warm forging. The metal is preheated, and the heating temperature is much lower than that of hot forging. Warm forging has higher precision, a smoother surface, and low deformation resistance.

4. Isothermal forging

Isothermal forging keeps the blank temperature constant during the entire forming process. Isothermal forging is to make full use of the high plasticity of certain metals at the same temperature or to obtain specific structures and properties. Isothermal forging requires keeping the mold and the bad material at a constant temperature, which requires high costs and is only used for special forging processes, such as superplastic forming.

Characteristics of Forging

Forging can change the metal structure and improve metal properties. After the ingot is hot forged, the original looseness, pores, micro-cracks, etc. in the cast state are compacted or welded. The original dendrites are broken up, making the grains finer. At the same time, the original carbide segregation and uneven distribution are changed. Make the structure uniform, to obtain forgings that are dense, uniform, fine, have good overall performance, and are reliable in use. After the forging is deformed by hot forging, the metal has a fibrous structure. After cold forging deformation, the metal crystal becomes orderly.

Forging is to make the metal flow plastically to form a workpiece of the desired shape. The volume of metal does not change after plastic flow occurs due to external force, and metal always flows to the part with the least resistance. In production, the shape of the workpiece is often controlled according to these laws to achieve deformations such as thickening, elongation, expansion, bending, and deep drawing.

The size of the forged workpiece is accurate and is conducive to organizing mass production. The dimensions of mold forming in applications such as forging, extrusion, and stamping are accurate and stable. High-efficiency forging machinery and automatic forging production lines can be used to organize specialized mass or mass production.

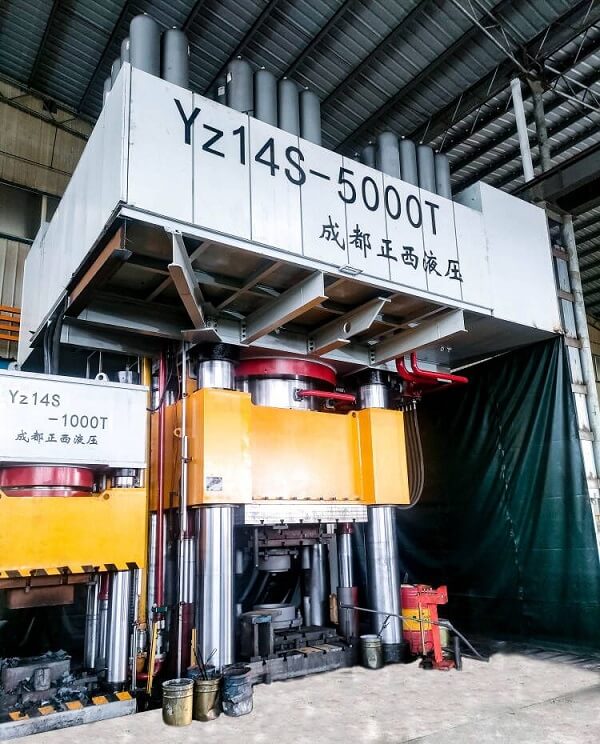

Commonly used forging machinery include forging hammers, hydraulic presses, and mechanical presses. The forging hammer has a large impact speed, which is beneficial to the plastic flow of metal, but it will produce vibration. The hydraulic press uses static forging, which is beneficial to forging through the metal and improving the structure. The work is stable, but the productivity is low. The mechanical press has a fixed stroke and is easy to implement mechanization and automation.

Development Trend of Forging Technology

1) To improve the intrinsic quality of forged parts, mainly to improve their mechanical properties (strength, plasticity, toughness, fatigue strength) and reliability.

This requires a better application of the theory of plastic deformation of metals. Apply materials with inherently better quality, such as vacuum-treated steel and vacuum-melted steel. Carry out pre-forging heating and forging heat treatment correctly. More rigorous and extensive non-destructive testing of forged parts.

2) Further develop precision forging and precision stamping technology. Non-cutting processing is the most important measure and direction for the machinery industry to improve material utilization, improve labor productivity, and reduce energy consumption. The development of non-oxidative heating of forging blanks, as well as high-hardness, wear-resistant, long-life mold materials and surface treatment methods, will be conducive to the expanded application of precision forging and precision stamping.

3) Develop forging equipment and forging production lines with higher productivity and automation. Under specialized production, labor productivity is greatly improved and forging costs are reduced.

4) Develop flexible forging forming systems (applying group technology, rapid die change, etc.). This enables multi-variety, small-batch forging production to utilize high-efficiency and highly automated forging equipment or production lines. Make its productivity and economy close to the level of mass production.

5) Develop new materials, such as forging processing methods of powder metallurgy materials (especially double-layer metal powder), liquid metal, fiber-reinforced plastics, and other composite materials. Develop technologies such as superplastic forming, high-energy forming, and internal high-pressure forming.

Post time: Feb-04-2024