Ufa wachitsulo wopanga ma press hydraulic atolankhani

Chimango

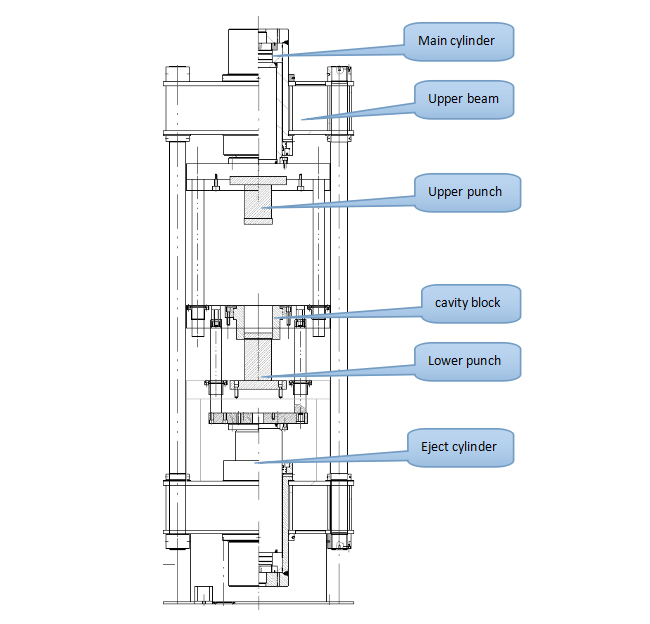

1) Kuzikuza kwa nkhungu kumapangidwa ndi 40cr ndi chitsulo 45 # popezera, kutembenuka ndikupera bwino kuti muwonetsetse zitsulo zokwanira komanso zofananira. Chitsogozo chimatengera kusanza zakuthupi kuti muteteze mawonekedwe ku Abrasion, monga chitsogozo cha mkuwa wa mkuwa. Ndi cr.

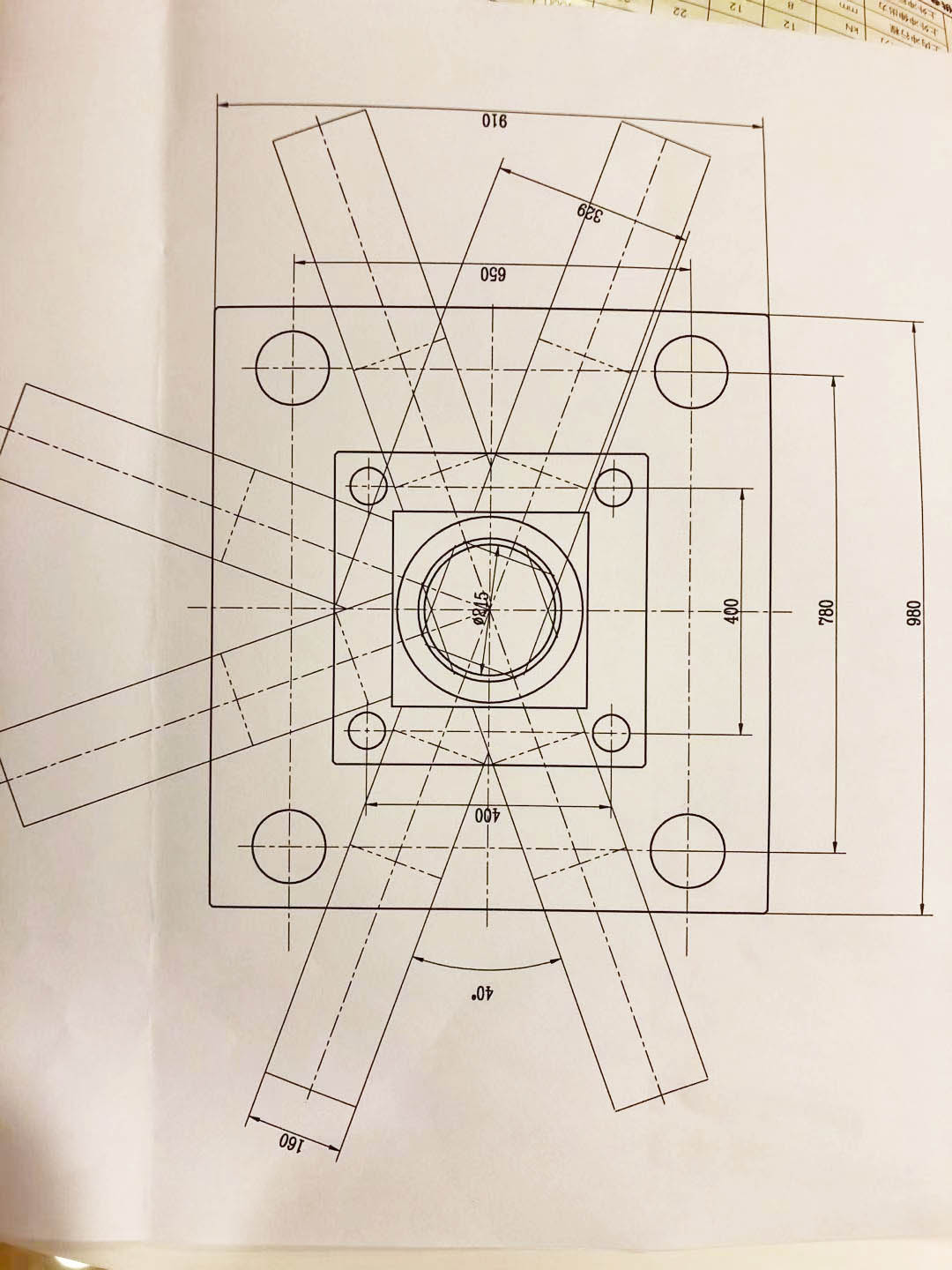

2) Gawo laukulu la nkhungu limakhala lokhotakhota kumtunda, ndipo punch kumtunda kwa nkhonya; Kuumba kwachikazi kumakhazikika pamaka tepolate, ndipo onse awiri ofuula ndikukakamiza kuponderezedwa kumachitika pakukakamiza. Posankhidwa mosamala, "ufa", woyandama, kukakamizidwa kuzengereza, kuchedwa kuchedwa, etc. kumatha kukwaniritsidwa mukakanikizidwa. Mukamasuntha ufa, kumtunda ndi wotsika mtengo wamasamba osokoneza bongo adayandama mwachidule ndi punch yapamwamba.

3) Njira yoyeserera ya Dealeadiation imayamba kuteteza chitetezo cha kusankha; Kuumba kwachikazi ndi magetsi kumakhazikika munthawi yomweyo komanso nkhungu yaikazi imakodwa kuti itulutsidwa mwachindunji nkhungu, ndipo kutulutsidwa kwamphamvu kwa akazi ndikothandiza kuteteza chinthucho kuti chisawonongeke mosavuta.

4) Kutalika kwa kutalika kwake, kulimbikira kwa zinthu kutalika ndi malo ogwiritsira ntchito zomwe zimapangitsa kuti athetse sensor ndi kuwongolera kwa plc Provice Kulondola kwa Makina, komanso malire.

5) Mtundu wosagwirizana umayikidwa pamalo olumikizirana pakati pa mbale yoyandama ndi kupindika kwa zitsulo zokhala ndi nsapato, ndipo ziwalo zonse za zitsulo sizimalumikizana ndi ufa waiwisi.

Dongosolo Lodyetsa

1. Njira yodyetsa idzakhala ndi chiyembekezo 6, ndipo chiopsezo chilichonse chidzalemetsa zinthu zosiyanasiyana.

2.Mundwe akhoza kuzungulira, ndipo wasindikizidwa bwino.

3. Kutumiza katundu wa zopangira, zingwe zilizonse 5-10.

4.Hopper Kugwira ntchito kungatheke ku HMI, 1,2,3, 10, kugwira ntchito limodzi.

5.6 Highper yayikulu idzakhazikitsidwa pamwamba pa makina, hop aliyense imatha kukweza makilogalamu 15 a ufa.

Mzati

Mizati yowongolera (zipilala) zidzapangidwaC45 Hot Hotning chitsuloNdipo khalani ndi ma chrome ozizira kwambiri 0.08mm. Ndipo chita chithandizo ndi kupsinjika.

MALANGIZO OTHANDIZA

JB / T3818-99"Mikhalidwe yaukadaulo ya Hydraulic Press"

GB52226.1-2002"Chitetezo cha Makina Ogwiritsa Ntchito Makina Ogwiritsa Ntchito Makina Ogwiritsa Ntchito 1: Zofunikira Kwambiri"

GB / T 3766-2001"Zofunikira zaluso za Hydraulic Systems"

GB17120-97"Press Presskery Chitetezo Chofunikira"

JB9967-99"Malire a Hydraulic Phokoso"

Thupi lalikulu

Mapangidwe a makina onse amatengera makina okweza makompyuta ndikusanthula chinthu cha Flite. Mphamvu ndi kukhwima kwa zida ndi zabwino, ndipo mawonekedwe ake ndi abwino. Magawo onse owala thupi amawombedwa ndi mphero yapamwamba kwambiri ya Q345B yamiyala yoyera, yomwe imawombedwa ndi kaboni dayokiti kuti iwonetsetse bwino.

Chozungulira

| Magawo | Fkulowelera |

| Mbiya ya cylinder |

|

| Rod rod |

|

| Zisindikizo | Khalani ndi mphete ya Japan Nok |

| Pisitoni | Kutsogozedwa ndi mitengo yamkuwa, kuvala bwino kukana, kuwonetsetsa kwa nthawi yayitali ya silinda |

Servo

1.Gervo dongosolo

Madongosolo a servo

Kusunga Magetsi

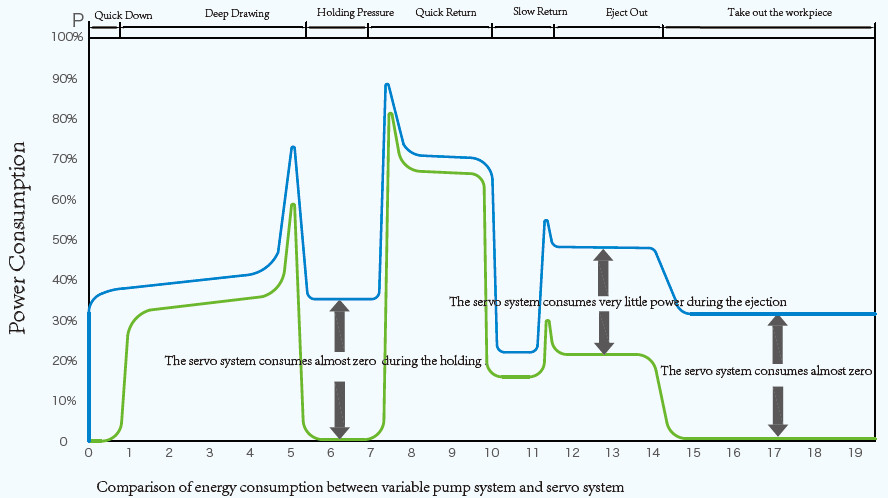

Poyerekeza ndi kampu yampufu yosinthika yosinthika, kayendedwe ka mafuta a servo amaphatikiza mawonekedwe othamanga a Servo ndi Mafuta Olimbitsa Mafuta Olimbitsa MagetsiKusunga ndalama kumatha kufikira 30% -80%.

Wamphamvu

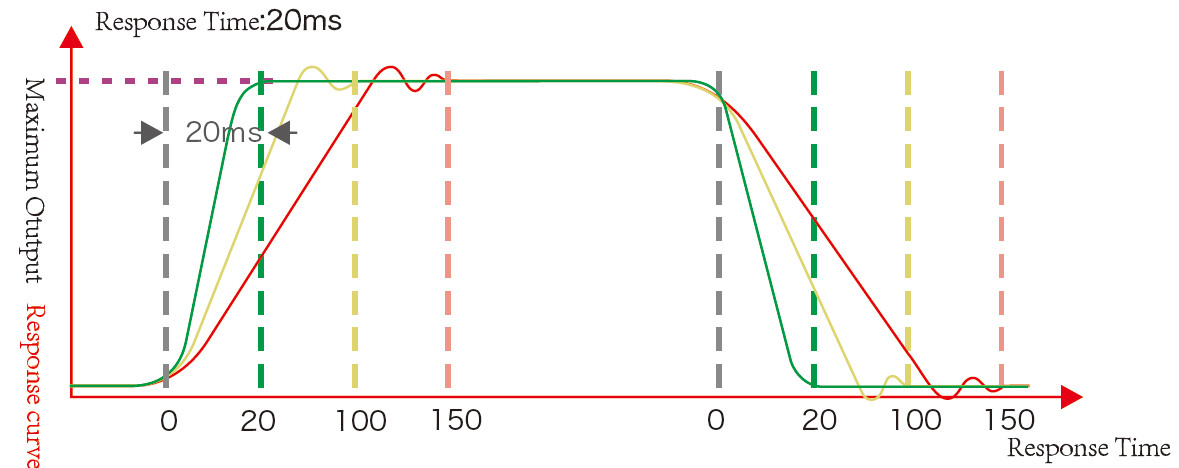

Kuthamanga kwa kuyankha ndi mwachangu komanso nthawi yoyankha ndi yochepa kwambiri ngati 20ms, yomwe imathandizanso kuyankha kwa hydraulic dongosolo.

Chidule

Kuthamanga kwachangu kumatsimikizira kulondola ndi kutseka kotseguka, mawonekedwe ake olondola amatha kufika 0.1mm, ndi ntchito yapaderayi ikuwonetsa kuti kulondola kungathetse± 01mm.

Kugwiritsa ntchito bwino kwambiri, njira yosangalatsa kwambiri ya algorithm imathandizira kuthamanga kosakhazikika ndi kusinthasintha kwa ochepera± 0,5 bar, kusintha kwa malonda.

Chitetezo Chachilengedwe

Phokoso: Phokoso lalikulu la hydraulic system ndi 15-20 DB yotsika kuposa ya pampu yoyambirira yosiyanasiyana.

Kutentha kwa servo kugwiritsidwa ntchito, kutentha kwa mafuta kwa magazi kumachepetsedwa mokwanira, zomwe zimawonjezera moyo wa chisindikizo cha Hydraulic kapena chimachepetsa mphamvu ya ozizira.

Chida Chachitetezo

Chitetezo chamagetsi chamagetsi chakumaso & kumbuyo

Kutseka ku TDC

Manja Awiri Ogwira Ntchito

Chithandizo cha inshuwaransi ya Hydraul

Chitetezo chowonjezera: valavu ya chitetezo

Madzimadzi amadzimadzi: Mulingo wamafuta

Chenjezo la kutentha kwa mafuta

Gawo lililonse lamagetsi liziwonjezera

Midadada ya chitetezo

Mafuta atseke amaperekedwa kwa magawo osuntha

Zojambula zonse za Press Incrolock Act, eg olimbikitsa sangagwire ntchito pokhapokha pabalaina kubwerera kumalo oyamba. Slide sangathe kusindikizidwa pomwe zolimbikitsa zikuyenda. Ngati kusamvana kuchitika, ma alarm amawonetsa pazenera ndikuwonetsa zomwe mkanganowu ndi.

Dongosolo la hydraulic

1.Oil tank idakhazikitsidwa ndi dongosolo lozizira lozizira (madzi obiriwira a mafakitale ozizira, ozizira pozungulira madzi, mafuta kutentha kumatha kukanikiza maola 24.)

2.Kusintha kwa hydraulic kumatengera dongosolo la cartridge la cartridd

3. Tanki yamafuta imakhala ndi fyuluta ya mpweya kuti mulumikizane ndi kunja kuti muwonetsetse kuti mafuta a hydraulic saipitsidwa.

4. Kulumikizana pakati pa valavu yodzaza ndi thankiyo imagwiritsa ntchito cholumikizira kuti muchepetse kugwedeza kwa thanki yamafuta ndikuthetsa vuto la kutayika kwa mafuta.