Mapeto achakudya ndi chivundikiro cha sitimayo ndipo ndi gawo lalikulu lopanikizika. Mtundu wa mutu umagwirizana mwachindunji ndi nthawi yayitali komanso yodalirika yodalirika ya sitimayo. Ndi chinthu chofunikira kwambiri komanso chofunikira kwambiri pakugawika mu petrochemicals, mphamvu ya atomiki, chakudya, mankhwala ena ambiri, ndi mafakitale ambiri.

Pankhani ya mawonekedwe, mitu imatha kugawidwa m'mitu yosanja, mitu yowoneka bwino, mitu yowuma, ndi mitu yozungulira. Mitu ya mitsempha yozungulira kwambiri komanso boilers imakhala yozungulira, ndipo mitu yowuma imagwiritsidwa ntchito kwambiri kwa kupanikizika kwapakatikati. Ochepa opindika ocheperako amagwiritsa ntchito mitu yowoneka bwino.

1. Njira yoyesera yomaliza

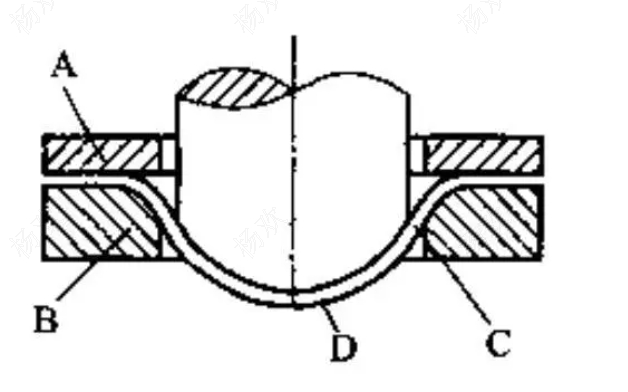

(1) Kusuntha. Kuzolowera kuchuluka, kukanikiza mitu yolimba ndi yaying'ono yomwe imafunikira mitu yambiri.

(2) spin. Ndioyenera mitu yayikulu ya ultra ndi yoonda. Makamaka pamakampani amakampani, omwe makamaka amaphatikizapo ntchito zazikulu komanso zotsika mtengo, zimakhala zoyenera kuzipindika. Mitu ya oval ndi yabwino kwambiri yopindika, pomwe mitu yodwala simagwiritsidwa ntchito ndipo mitu yozungulira imakhala yovuta kwambiri kukanikiza.

2. Madandaulo aintaneti ndi zida

(1) Kuphika zida: chitofu. Malo owonetsera amagwiritsidwa ntchito potenthetsa, ndipo kutentha mafuta kapena mpweya kumagwiritsidwa ntchito monga momwe tingathere. Chifukwa imadziwika ndi kuyankha koyera, mphamvu yayikulu, kutentha kosaka kutentha, komanso kuvuta kwambiri ndikuyamba kuwonongeka. Ng'ombe yotentha iyenera kukhala ndi chida choyezera kutentha komanso kujambula kutentha

.

(2)Phatikizani. Pali mitundu iwiri: Kuchita kamodzi ndi zochitika kawiri.

Chochita chimodzi chimatanthawuza sindamping yokhazikika ndipo palibe sinlinder wopanda kanthu. Mafakitale ochepa komanso apakatikati amagwiritsa ntchito. Mafakitale akuluakulu onse amagwiritsa ntchito zochita kawiri, ndiye kuti, pali silinda wamba komanso silinda.

Kutumiza kwamitundu ya hydraulic ndi madzi. Ndi yotsika mtengo, imasunthika mwachangu, siyikhala yokhazikika, ndipo ilibe ngati mfundo zapamwamba monga makina a hydraulic. Mphamvu yake ndiyotsika kuposaHydraulic Press, ndipo zofunikira za chiwongolero sizokhwima. Kusindikizidwa kwa makina a hydraulic kumakhala kokhazikika ndipo kumakhala ndi zofunikira kwambiri kusindikizidwa ndi chitsogozo.

.

3. Zinthu zomwe zikukhudza khoma lakuda lamutu

Pali zinthu zambiri zomwe zimakhudza kusintha m'matumbo, zomwe zitha kufotokozedwa mwachidule motere:

(1) katundu wakuthupi. Mwachitsanzo, kuchepa kwa chidindo chofikitsa kwa mutu kuli kwakukulu kuposa komwe kwa kaboni.

(2) mutu. Mutu wooneka bwino wa disc uli ndi kuwonda kocheperako, mutu wozungulira uli ndi kuwonda kwakukulu, ndipo mutu wa elliptic uli ndi sing'anga.

(3) Chokulirapo kumwalira radius, yaying'ono yaying'ono.

.

(5) Matenda opatsirana ndi abwino komanso kuchuluka kwa kupatulira ndikochepa.

(6) Kutentha kwambiri kutentha, kuchuluka kwakukulu.

4. Kanikizani ndikupanga thELADE DATO

. Mafuta ayenera kugwiritsidwa ntchito ku nkhungu musanalowe.

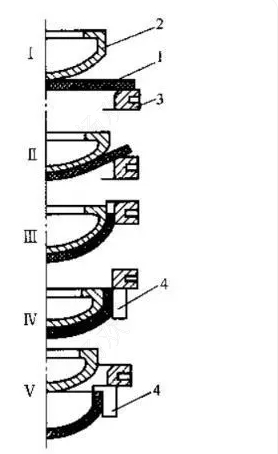

. Kupatuka pakatikati pazachilendo komanso nkhungu yotsika iyenera kukhala yochepera 5mm. Mukamakakamiza mutu wokhomedwa, chidwi chiyenera kulipidwa ndikuyika kutseguka kwa elliptical pamalo omwewo ngati ma axes zazifupi komanso zazifupi za nkhungu. Panthawi yokakamiza, choyamba, sinthanitsani kubowola ndi malo otseguka ndikutuluka. Kanikizani mpaka pamlingo wokwera pang'ono kuposa ndege ya nkhungu (pafupifupi 20mm), kenako akanikizire umunsi pansi kachiwiri. Bowo la dzenje limagwera nthawi yomweyo kuti mukakanikize mutu. Pakukanikiza, mphamvu yopukutira imafunika kuwonjezeka pang'onopang'ono kuchokera yaying'ono mpaka lalikulu ndipo sikuyenera kuwonjezeka mwadzidzidzi.

. Osayiyika polowa. Osamata zidutswa ziwiri pamwamba pa wina ndi mnzake musanazizire kutentha. Panthawi yokhazikika, kutentha kwa mafa kumatsika pafupifupi 250 ° C ndi malo osanja sikuyenera kupitilizidwa. Ntchito imatha kupitiliza pambuyo pozizira njira zozizira zimatengedwa kuti muchepetse kutentha kwa amwalira.

(4) Mutu wokhomeredwa uyenera kupangidwa mu gawo limodzi momwe mungathere. Ngati sizingatheke kupanga nthawi imodzi chifukwa cha zovuta zomwe zimachitika, chidwi chiyenera kulipidwa kwa cholowa ndi mutu mukamamenya dzenjelo, ndipo chisamaliro chikuyenera kulipidwa kukhoma la makulidwe a bowo.

5..Ming Hydraulic Press

Zimathamanga komanso zosinthika mu mtundu wa ntchito, zimakhala ndi kudalirika kwakukulu, ndipo ndizothandiza.

Kuyenererana kwa mutu wowonda.

Makina osindikizira amatenga mawonekedwe anayi.

■ Slider Slider ali ndi adapter yoyenda bwino.

■ Stroke of the Scarmer yopanda kanthu ndikusintha.

■ Mphamvu zopanda kanthu komanso mphamvu zotambalala zimatha kusintha zokha.

Itha kuzindikira chilichonse komanso kuchitapo kanthu kawiri.

6..

Kuyenererana kwa ozizira.

Makina osindikizira amatenga mawonekedwe anayi.

Makina otambalala ali ndi nkhungu yapamwamba, nkhungu yotsika, kulumikizana kwa nkhungu, komanso chipangizo chosintha mwachangu.

■ Mphamvu zopanda kanthu komanso mphamvu zotambalala zimatha kusintha zokha.

Post Nthawi: Meyi-09-2024