1. Kukhululuka kwaulere

Kudziletsa kwaulere kumatanthauza njira yogwiritsira ntchito zida zothandizira wamba kapena kugwiritsa ntchito mphamvu yakunja kwa ma alvis am'munsi komanso otsika kwambiri.

Kutha kwaulere kumapangitsa kuti atuluke m'matumba ang'onoang'ono. Zida zopepuka monga kufera nyundo ndi nyuzipepala zomwe zimagwiritsidwa ntchito popanga zowonjezera kuti zitheke. Kukhazikitsa kwaulere kumatengera njira yopezera kutentha.

Njira yokhululukirira imaphatikizapo njira yoyambira, njira yothandiza, komanso njira yomalizira.

Njira yopezera yaulere yokhumudwitsa, kujambula, kupukutira, kupindika, kupindika, komanso kuphweka, kujambula, ndi kusefukira.

Njira yothandizira: Njira yosinthira isanakwane, monga kukanikiza nsagwada, kukanikiza m'mphepete mwa chitsulo, kudula phewa, etc.

Njira yomaliza: njira yochepetsera zolakwika zapamwamba, monga kuchotsa zosasinthika ndi kuwumbika.

Mwayi:

(1) Kusinthasintha ndi kwakukulu, kumatulutsa zidutswa zazing'ono zosakwana 100,000g. Ndipo imathanso kutulutsa zidutswa zolemera mpaka 300t.

(2) Zida zomwe zimagwiritsidwa ntchito ndizovuta zambiri zolingana.

. Chifukwa chake, toning ya zida zopepuka zimafunikira kuti zitheke kukhala zazing'ono kwambiri kuposa zomwe wathetsa.

(4) Zofunikira zolondola za zida.

(5) Kuzungulira kwake kumachepa.

Zovuta:

(1) Kuchita bwino kumakhala kochepa kwambiri kuposa kufa.

(2) Kutulutsidwa kumakhala ndi mawonekedwe osavuta, kulondola kotsika, komanso malo owuma.

(3) Ogwira ntchito amagwira ntchito kwambiri ndipo amafunikira maluso apamwamba.

(4) Sizovuta kuzindikira makina ndi muyeso.

2.

Imfa ikutanthauza njira yomwe mwapeza yomwe imasiyidwa imapezeka ndikupanga zikwangwani zokhala ndi zida zapadera zopepuka. Kutalika kumene kumapangidwa ndi njirayi ndi kotsimikizika kukula, zazing'ono pololedwa, zovuta pakupanga, komanso kukwera bwino.

Kusankhidwa malinga ndi zida zomwe zagwiritsidwa ntchito: kufa kungopeza nyundo, kufa ndi mwayi wosindikizira, kufa ndi kungopeza makina olekanitsa, kufa ndi akatswiri osindikizira, etc.

Ubwino:

(1) Kupanga kwapamwamba kwapamwamba. Pa nthawi yongopezera, kuwonongeka kwa chitsulo kumachitika mu dive, kotero mawonekedwe omwe mukufuna akhoza kupezeka mwachangu.

(2) Kuyiwala ndi mawonekedwe ovuta kungapangidwe.

.

.

(5) Sungani zida zachitsulo ndikuchepetsa kudula ntchito.

(6) Pansi pa minda yokwanira, mtengo wa magawo umatha kuchepetsedwa.

Zovuta:

.

(2) Kupanga kwamwalira kwa kufa kwa nthawi yayitali ndipo mtengo wake ndi wokwera.

.

3. Kwezerani

Lowetsani kutanthauza njira yomwe imapangidwira yomwe imapangika yomwe imapangika yomwe imapangika yomwe imapangika yomwe imapangika imagwiritsidwa ntchito kuti ithe kusokoneza billet kuti mupeze zomwe mungafune kapena kukhululuka.

Kuletsa kulakwitsa ndi kusokonekera kovuta katatu. Zambiri mwazinthu zopunduka zimayenda motsatira gawo lalitali kuti muwonjezere kutalika kwa billet, ndipo gawo laling'ono la zinthuzo limayenda pambuyo pake kuti muwonjezere gawo la billet. Panthawi yopeza ndalama, malo oyambira a billet amachepetsa mosalekeza. Njira yopezera ndalamayo imagwiritsa ntchito mfundo yopukutira kuti isamveke pang'onopang'ono.

Kupeza koyenera ndikoyenera njira zolekanitsa monga ma shafts okwera, ogubuduza shot, ndi kugawa zida pamfundo yotalika. Lowetsani kuti igwiritsidwe ntchito kuti mupange ndodo zolumikizira, zopondaponda zobowola zobowola, mitengo yamphesa, misewu, mabowo, ndi masamba a turbine, etc.

Poyerekeza ndi kufa wamba, mbikani ndi maubwino a kapangidwe kabwino, kupanga kokhazikika, kugwedezeka kochepa, komanso luso lophweka kwambiri.

4. Turo amwalira

Tayala Ife Luti Kukhululuka Ndi Njira Yopezera Njira Yomwe Imatengera njira yopezera yaulere kuti ikhale yopanda kanthu, kenako ndikupanga mu thambo. Ndi njira yopezera pakati pakukhululuka ndi kufa. Amagwiritsidwa ntchito kwambiri m'magulu ang'onoang'ono komanso osalutsidwa ndi zochulukirapo kumwalira ndi ambiri a iwo ndi omwe ali ndi anthu omasuka.

Pali mitundu yambiri yamatayala omwe amagwiritsidwa ntchito mu taled Moder Worder, ndipo ogwiritsidwa ntchito popanga dontho, nkhungu nkhungu, hufuion chimawumba, etc.

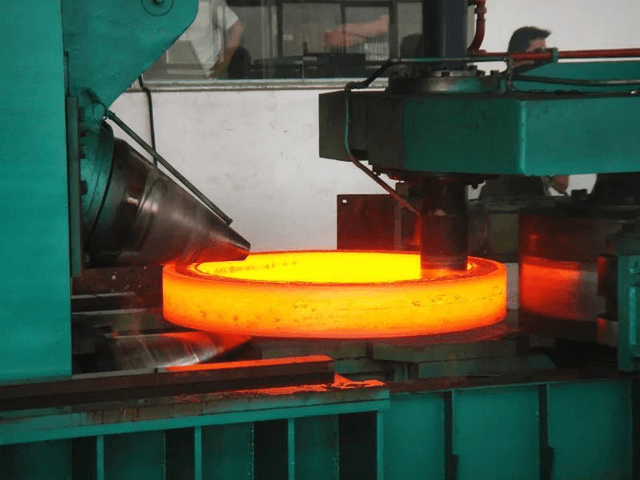

Cylinder yotseka imafa imagwiritsidwa ntchito kwambiri pakupeza kopepuka kwa Rotary. Mwachitsanzo, magiya okhala ndi mabwana onse pamapeto nthawi zina amagwiritsidwa ntchito popewetsa osamveka. Cylinder yotsekedwa imafa kuti itheke ndi kungotha kwaulere.

Chifukwa cha Turning zolemetsa ndi mawonekedwe ovuta, ndikofunikira kuwonjezera theka la mawonekedwe awiri (ndiye kuti, onjezerani gawo) mu cylinder nkhungu kuti mupange sing'anga wophatikizira wophatikizira. Ndipo zopanda pake zimapangidwa m'manja mwa theka lamimba.

Kanemayo nthawi zambiri amapangidwa ndi magawo awiri, owuma komanso otsika. Kuti mufanane ndi kutsika kwapamwamba komanso yotsika kuti zisasungunuke, zowongolera posts ndi zikhomo zowongolera nthawi zambiri zimagwiritsidwa ntchito poiyika. Kumata kumagwiritsidwa ntchito kwambiri kugwiritsidwa ntchito sikunatuluke osakanikirana ndi mawonekedwe ovuta, monga ndodo zolumikizira, malo owoneka bwino, etc.

Poyerekeza ndi kukhululukidwa kwaulere, tayala kufa kukhululukidwa ali ndi zotsatirazi:

(1) Popeza zolembedwazo zimapangidwa mu divel

(2) Kugawidwa kwa minofu minofu ndi koyenera, kotero khalidweli ndilokwezeka.

. Popeza mawonekedwe a mawonekedwe oletsedwa amayang'aniridwa ndi mafamu, opanda kanthu amapangidwa mwachangu. Ndipo zokolola ndi 1 mpaka 5 zopamwamba kuposa zomwe wadzikhululukirira.

(4) Pali malo ochepa otsalira, ndiye kuti chilolezo chamakina ndichaching'ono. Izi sizimangopulumutsa nkhani zachitsulo komanso zimachepetsa ma prinang maola.

Zovuta:

.

(2) Kungowunika kochepa kumatha kupangidwa;

.

.

.

Zhengxi ndi wodziwika bwinoWopanga Makina ku China, kupereka mitundu yosiyanasiyana ya makina osindikizira, kuphatikiza makina okhululukika kwaulere, kufa ndi makina owombola,makina owonera otentha, Makina Ozizira Ozizira, ndipo makina opipitsa, etc. Ngati muli ndi zosowa zilizonse, chonde lemberani.

Post Nthawi: Jun-30-2023