Kuunikira ndi dzina loti lizipirira ndi kusanja. Ndi njira yosinthira yomwe imagwiritsa ntchito nyundo, kuwongolera makina olekanitsa kapena nkhungu kuti ikhale yovuta kwambiri kuti muchepetse magawo a pulasitiki kuti apeze mawonekedwe ofunikira ndi kukula kwake.

Zomwe zakhululukidwa

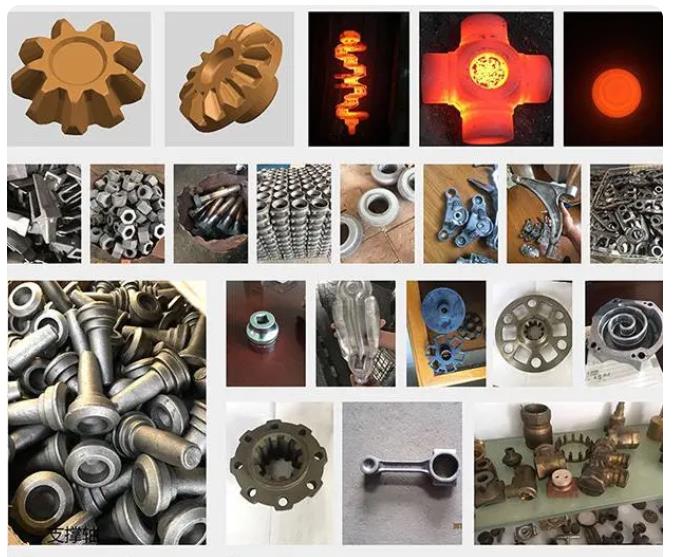

Panthawi yopepuka, chilichonse chopanda kanthu chimakhala choyipa kwambiri pulasitiki komanso kuchuluka kwapulasitiki. M'machitidwe okhazikika, opanda kanthu amapangidwa ndi kusintha kwa malo amtundu uliwonse, ndipo palibe oyenda papulasitiki pamwamba kwambiri mkati mwake. Kukhululukidwa kumagwiritsidwa ntchito makamaka kukonza zitsulo. Itha kugwiritsidwanso ntchito kuwongolera zitsulo zina, monga ma pulasitiki, monga ma pulasitiki, mphira, zingwe zamiyendo, njerwa, ndi kapangidwe kazinthu zophatikizika.

Kugubuduza, kujambula, etc. Poletsedwa ndi zitsulo ndi mafilimu onse apulasitiki kapena apikisano. Komabe, kulephera kumagwiritsidwa ntchito kupanga zigawo zachitsulo, pomwe kugudubuka ndi zojambula zimagwiritsidwa ntchito kupangira zitsulo zambiri monga ma mbale, zingwe, mapaipi, ndi mawaya, ndi mawaya.

Kukakamizidwa Kukhululukidwa

Kukhululukidwa kumayankhidwa makamaka malinga ndi njira yopanga ndi kutentha kwamitundu. Malinga ndi njira yopanga, kuwunika kungathe kugawidwa m'magulu awiri: Kupeweka ndi Kusuntha. Malinga ndi kupuma kopumira, kulekanitsa kungathe kugawidwa kuti muthetse kutentha, kungotha kufooka, kungopeza bwino, komanso kungotha, etc.

1. Kungotha

Kungopeza bwino ndikupeweka kuchitika pamwamba pa kutentha kwa chitsulo. Kuchulukitsa kutentha kumatha kukonza ma pulasitiki, omwe ndi opindulitsa kusintha mtundu wazomwe amagwira ntchito ndikupangitsa kuti zisathe kusweka. Kutentha kwambiri kumathanso kuchepetsa kukana kwachitsulo ndikuchepetsaMakina Opepuka. Komabe, pali njira zambiri zopewera kutentha, kusamala kwa malo ndi osauka, ndipo pamwamba siosalala. Ndipo zotulukazi zimakonda kupezeka kwa oxidation, dekarburization, ndi kuwonongeka koyaka. Wogwira ntchito ndi wamkulu komanso wandiweyani, zinthuzo zimakhala ndi mphamvu kwambiri komanso pulasitiki zotsika kwambiri (monga zokutira zamiyala yayitali, ndi zina), ndipo kungopeza kotentha kumagwiritsidwa ntchito.

Nthawi zambiri amagwiritsa ntchito kutentha kwa kutentha ndi: kaboni 800 ~ 1250 ℃; Alloy amajambula zithunzi 850 ~ 1150 ℃; liwiro lalitali kwambiri 900 ~ 1100 ℃; kawirikawiri aluminium aloy 380 ~ 500 ℃; Aloy 850 ~ 1000 ℃; Brass 700 ~ 900 ℃.

2. Kupirira kuzizira

Kupeza kuzizira kumangoyesedwa pansi pa kutentha kwa zitsulo. Nthawi zambiri, kukhululuka kuzizira kumatanthauza kuti ndi kutentha kwa firiji.

Zojambula zopangidwa ndi kuzizira pokhazikitsa kutentha kwa chipinda zimakhala zolondola komanso ziwonetsero zowoneka bwino, mawonekedwe osalala, njira zochepa zopangira zokha. Magawo ambiri ozizira komanso ozizira amatha kugwiritsidwa ntchito mwachindunji ngati magawo kapena zinthu popanda kufunika pamakina. Komabe, nthawi yozizira kulolera, chifukwa cha pulasitiki yotsika, kusokonekera ndikosavuta kuchitika pakusintha ndi kuwonongeka kwake ndikosavuta, ndikufunikira makina otayira totage-tonnige.

3. Kukhululuka kwabwino

Kungoletsa kutentha kwambiri kuposa kutentha kwabwinoko koma osapititsa kutentha kutentha kumatchedwa kutentha. Chitsulo chimasakidwa, ndipo kutentha kwa kutentha kumakhala kochepa kwambiri kuposa kungopeza bwino. Kungolitsa kwabwino kumakhala kolondola kwambiri, malo osalala, komanso kuwonongeka kochepa.

4..

Kukhazikitsa ma isothermal kumasunga kutentha kosatha nthawi yonse yopanga. Kungokhazikitsa ndi kugwiritsa ntchito chitsulo chapamwamba kwambiri kutentha komweko kapena kupangira zojambulajambula ndi katundu. Njira yopezereka imafunikira kuti nkhungu ndi zonyansa pamatenthedwe nthawi zonse, zomwe zimafuna ndalama zambiri ndipo zimangogwiritsidwa ntchito pokhapokha ngati kungokwezedwa kwapadera.

Makhalidwe Ofuna Kupeza

Kungopeza kungasinthe kapangidwe kazitsulo ndikusintha zinthu zitsulo. Itate atangopangidwa, omasuka, ma pores, ming'alu ya micro, etc. Mu boma loponyedwa ndi ophatikizika kapena owala. Makina oyambirirawo amaletsedwa, ndikupanga mbewu zabwino. Nthawi yomweyo, tsankho loyambirira la mankhwala ndi magawidwe osinthika asinthidwa. Pangani yunifolomu, kuti mupeze zowawa, yunifolomu, muli bwino, khalani odalirika. Pambuyo polemedwa ndi wokhululuka, chitsulo chimakhala ndi mawonekedwe opindika. Pambuyo pochepetsa kuzizira, Christstal imakhala mwadongosolo.

Kukhululukidwa ndikupangitsa kuti zitsulo zisunthe kwambiri kuti zipangitse mawonekedwe omwe mukufuna. Kuchuluka kwa chitsulo sikusintha pambuyo pa pulasitiki kumachitika chifukwa cha mphamvu yakunja, ndipo chitsulo nthawi zonse chimayenda mbali ndi kukana pang'ono. Popanga, mawonekedwe a ntchitoyi nthawi zambiri amalamuliridwa malinga ndi malamulowa kuti akwaniritse zowonongeka monga kukula, mlengalenga, kukulira, kuwerama, ndikujambula, ndikujambula.

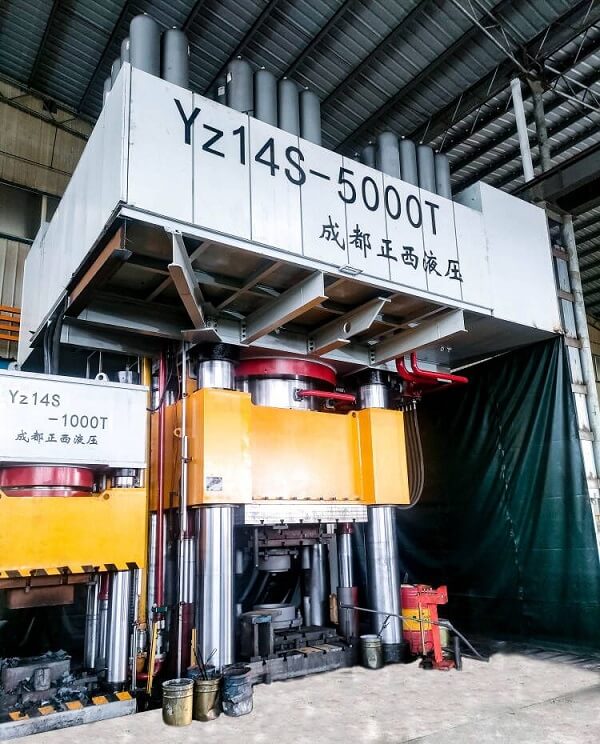

Kukula kwa ntchito yopangidwa ndi yomwe idapangidwa ndi kolondola ndipo imakhala yolimba kukonza misa. Kukula kwa mawonekedwe a nkhungu pantchito monga kulekanikirana, potuluka, ndipo chitseko ndi cholondola komanso chokhazikika. Makina Okhazikika Kwambiri ndi Mizere Yopanga yokhayokha imatha kugwiritsidwa ntchito kukonza misa kapena mafuta ambiri.

Makina opindika kwambiri amaphatikizira kuti athetse nyundo,makina a hydraulic, ndi makina makina. Hamu yoletsedwa imakhala ndi liwiro lalikulu, lomwe limakhala lopindulitsa pa pulasitiki yazitsulo, koma imapanga kugwedezeka. Press Press Hydraulic imagwiritsa ntchito chokhazikika, chomwe chingapindule ndikuthana ndi zitsulo ndikusintha kapangidwe kake. Ntchitoyi ndi yokhazikika, koma zokolola ndizochepa. Makina osindikizira ali ndi stroke yokhazikika ndipo ndi yosavuta kukhazikitsa magwiridwe antchito ndi muyeso.

Chitukuko cha chitukuko chokhululuka

1) Kusintha kwa mawonekedwe a chidwi cha zomwe mwapanga, makamaka kuti zithandizire mphamvu zawo (mphamvu, pulasitiki, mphamvu, kutopa, kudalirika.

Izi zimafuna kugwiritsa ntchito bwino lingaliro la kufooka kwa pulasitiki. Gwiritsani ntchito zida zokhala ndi zabwino zomwe zili bwino, monga chitsulo chachitsulo chosinthika komanso chosungunuka. Chitani zoterera kale ndi kungochotsa kutentha kutentha. Kuyesa kwambiri ndi kofalikira kochepa kosawonongeka.

2) Kuyambiranso kukhazikika koyenera komanso mwaluso. Kusintha kosadulira ndikofunikira kwambiri ndi njira yofunikira kwambiri pamakina ogulitsa makina kuti apititse patsogolo kugwiritsa ntchito zinthu zolimbitsa thupi, kusintha ntchito zokolola, ndikuchepetsa kugwiritsa ntchito mphamvu. Kukula kwa oxidatikiti yopenyeratu, komanso kuvuta kwambiri, kuvala zida zolimba, zazitali komanso njira zochizira pamtunda, zimapangitsa kuti pakhale njira yolerera komanso yolondola.

3) Khalani ndi zida zopepuka ndikutha kungopanga mizere yopindulitsa kwambiri ndi makina ogwiritsa ntchito okha. Pansi pa ntchito zapadera, ntchito zokolola zantchito zili bwino komanso zopepuka zimachepetsedwa.

4) Kupanga makina osinthika osinthika (kugwiritsa ntchito ukadaulo wamagulu, kusintha kwamwalira mwachangu, etc.). Izi zimathandizira kupanga mitundu yambiri, yaying'ono yokhazikitsa kugwiritsa ntchito bwino - kugwiritsa ntchito bwino ndi zida zongokhazikitsa kapena mizere yopanga. Pangani zokolola zake pafupi kwambiri ndi kuchuluka kwa zochulukirapo.

5) Pezani zida zatsopano, monga kungolitsa njira zopangira ma metaldelgy (makamaka azitsulo zamitundu iwiri), zitsulo zamadzimadzi, zitsulo zolimbitsa thupi, ndi zida zina zolimbitsa thupi. Chotsani ukadaulo monga mawonekedwe apamwamba, mawonekedwe apamwamba kwambiri, komanso mawonekedwe apamwamba kwambiri.

Post Nthawi: Feb-04-2024