Ovomerezeka Ferrit Magnetic hydraulic Press

Zolinga za makinawo: Kanikizani (kuphatikiza magetsi a wildulic), pusiki yamagetsi yamagetsi, nduna zamagetsi, jini yosakaniza, thanki ya vacuum; Chingwe chowumbika, chopanda pake chotsika pamakina.

Whatsapp: +86 176 0282 8986

Zoyambira Zaukadaulo

1) Pulogalamu ya geear hydraulic system imagwiritsidwa ntchito kuziziritsa mafuta kuti apange kukakamizidwa, kukhazikika komanso kudalirika mukamagwiritsidwa ntchito mosalekeza kwa nthawi yayitali;

2) Kugwiritsa ntchito mphamvu zochepa komanso kupulumutsa mphamvu. Kugwiritsa ntchito mphamvu kwa makina onse ndi ofanana ndi a 150-akanikizirani ma ton, ndipo kutulutsa kwa kusuntha kuli 53% kuposa momwe matani a 150-ton;

3) Kukhazikika kwa nkhungu umakhazikika pa wolandila, ndipo magawo owumbirawo amatha kusakazidwa mwachangu ndikusinthidwa pomwe nkhungu itasinthidwa, ndipo nkhungu ndi nkhungu ndi yodziyimira pawokha;

4) Thupi lalikulu limatulutsa thupi (kapena) matupi a chitsulo, ndipo magwiridwe apamwamba ndi otsika, opanga nkhuni, waya wamadzimadzi, ndi zonse zomangirira zitsulo. Mphamvu yayikulu, kapangidwe kake, malo ang'onoang'ono okhazikitsa dongosolo kapena osavomerezeka kutenga;

5) Chigawo chachikulu ndi cholumikizira cha-gawo limodzi, zomwe zimatengera waya wokhazikika.

6) Kulumikizana ndi Screen ndi sensor kuzindikira makina amakina azamanja, kupewa kupewa ndi kosavuta komanso mwachangu;

7) Zigawo za hydraulic za malo okwerera pampompo zimagwiritsa ntchito ma valves aukadaulo,

8) kukwaniritsa zotsika-madzi otsika (34% Madzi)) jakisoni wokha, wokhazikika komanso wodalirika

Mlandu wamakampani

Magawo a Makina

| Dzina | Lachigawo | Peza mtengo | |

| Mtundu | / | Yf-230t | |

| Mphamvu yapamwamba ya cylinder | KN | 2300 | |

| Werlinder Cylinder Diameter | mm | 360 | |

| Chapamwamba cylinder stroke | mm | 495 | |

| Mphamvu Yotsika ya Cylinder | KN | 1000 | |

| Maondo a Cylinder | mm | 250 | |

| Kuchepetsa cylinder stroke | mm | 145 | |

| Kuthamanga kwa Ram | Kutseka | mm / s | >180 |

| Kuyandikira | mm / s | 2-10 | |

| Pang'onopang'ono | mm / s | 0.02-1.5 (kusintha) | |

| Kukanikiza mwachangu | mm / s | 0.1-2.5 (kusintha) | |

| Bwelera | mm / s | >90 | |

| Kuthamanga Kwambiri | Tulutsa | mm / s | 20 |

| Bwelera | mm / s | 35 | |

| Max. Malo aulere am'mwamba komanso otsika | mm | 1080 | |

| Kukula kwabwino (kutalika x m'lifupi) | mm | 1460 × 860 | |

| Phukusi lokhazikika | / | Makina oyenda ozizira a mpweya 100000mpere-nthawi | |

| Max. kuchuluka kwa jekeseni | L | 4.1 | |

| Max. Kuyika osakanizira | L | 180 | |

| Mphamvu zonse za makina onse | KW | 65 | |

| Maziko a Mombe | / | 550mm kusiyana pakati pa mafunde a nkhungu, kutalika 300mm | |

| Nthawi yozungulira | S | <60 | |

Mzati

Mizati yowongolera (zipilala) zidzapangidwaC45 Hot Hotning chitsuloNdipo khalani ndi ma chrome ozizira kwambiri 0.08mm. Ndipo chita chithandizo ndi kupsinjika.

Thupi lalikulu

Mapangidwe a makina onse amatengera makina okweza makompyuta ndikusanthula chinthu cha Flite. Mphamvu ndi kukhwima kwa zida ndi zabwino, ndipo mawonekedwe ake ndi abwino. Magawo onse owala thupi amawombedwa ndi mphero yapamwamba kwambiri ya Q345B yamiyala yoyera, yomwe imawombedwa ndi kaboni dayokiti kuti iwonetsetse bwino.

Chozungulira

| Magawo | Fkulowelera |

| Mbiya ya cylinder |

|

| Rod rod |

|

| Zisindikizo | Khalani ndi mphete ya Japan Nok |

| Pisitoni | Kutsogozedwa ndi mitengo yamkuwa, kuvala bwino kukana, kuwonetsetsa kwa nthawi yayitali ya silinda |

Servo

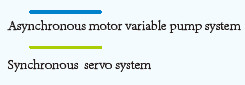

1.Gervo dongosolo

Mfundo za kuwongolera kwa servo

Chipinda chachikulu cha cylinder chapamwamba chokhala ndi zovuta, kutsekedwa ndi omwe adasamukira ku Syyror wolamulira. Malinga ndi chizindikiro chopanikizana, malo omwe ali ndi malingaliro, kukakamizidwa komwe kumaperekedwa, malo operekedwa ndi siginecha yopatsidwa kuti awerenge kuthamanga kwa servo, kuti athetse pampuyo kuti itulutse, kuthamanga ndi kuwongolera.

Osindikiza amatengera pid kuti asinthe kukakamiza ndi kuthamanga kwa servo mota kuti ayambe kuwongolera. Posintha liwiro la mota la servo, limatha kuwongolera kupsinjika, kuthamanga, maudindo ndi magawo ena a valavu yowongolera, pochotsa makina ena owongolera ndi zinthu zina mu dera la hydraulic kuti muchepetse.

Masitepe a servo

Kusunga Magetsi

Poyerekeza ndi kampu yampufu yosinthika yosinthika, kayendedwe ka mafuta a servo amaphatikiza mawonekedwe othamanga a Servo ndi Mafuta Olimbitsa Mafuta Olimbitsa MagetsiKusunga ndalama kumatha kufikira 30% -80%.

Wamphamvu

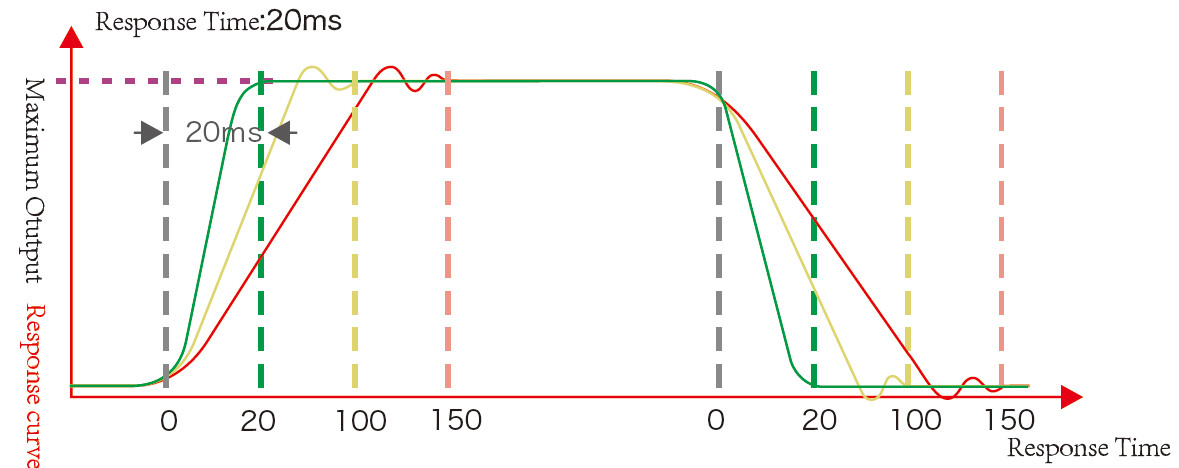

Kuthamanga kwa kuyankha ndi mwachangu komanso nthawi yoyankha ndi yochepa kwambiri ngati 20ms, yomwe imathandizanso kuyankha kwa hydraulic dongosolo.

Chidule

Kuthamanga kofulumira kumatsimikizira kutseguka ndikutseka kolondola, mawonekedwe ake olondola amatha kufika 0.1mm, ndi ntchito yapaderayo ndikukhazikitsa kulondola kungathetse ± 0.01mm.

Kugwiritsa ntchito bwino kwambiri, kuyankha kwakukulu kwa algorithm kumathandizira kukakamizidwa kokhazikika ndi kusinthasintha kwa ocheperachepera ± 0,5 bar, kukonza malonda.

Chitetezo Chachilengedwe

Phokoso: Phokoso lalikulu la hydraulic system ndi 15-20 DB yotsika kuposa ya pampu yoyambirira yosiyanasiyana.

Kutentha kwa servo kugwiritsidwa ntchito, kutentha kwa mafuta kwa magazi kumachepetsedwa mokwanira, zomwe zimawonjezera moyo wa chisindikizo cha Hydraulic kapena chimachepetsa mphamvu ya ozizira.

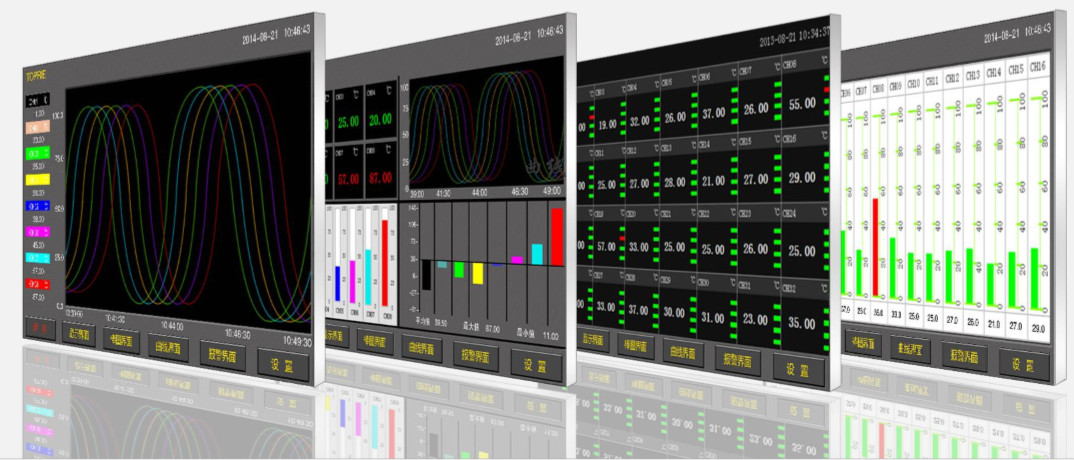

Machitidwe

Makompyuta am'madzi am'madzi ambiri amazindikira magawo akulu ndi cholakwika cha matolankhani, makamaka kuphatikiza izi:

● Pindana(MPA, ℃) ● Chinsinsi Chotetezedwa ● Kuwonetsera kwa digito ● Kuchita Chida

| Malo opumira, 0 pa nthawi yotseguka Kutulutsa kwa mpweya | Chithandizo kuzungulira, gawo mu pulogalamuyi.clamp kuthamanga Kuthamanga

|

Chida Chachitetezo

Chitetezo chamagetsi chamagetsi chakumaso & kumbuyo

Kutseka ku TDC

Manja Awiri Ogwira Ntchito

Chithandizo cha inshuwaransi ya Hydraul

Chitetezo chowonjezera: valavu ya chitetezo

Madzimadzi amadzimadzi: Mulingo wamafuta

Chenjezo la kutentha kwa mafuta

Gawo lililonse lamagetsi liziwonjezera

Midadada ya chitetezo

Mafuta atseke amaperekedwa kwa magawo osuntha

Zojambula zonse za Press Incrolock Act, eg olimbikitsa sangagwire ntchito pokhapokha pabalaina kubwerera kumalo oyamba. Slide sangathe kusindikizidwa pomwe zolimbikitsa zikuyenda. Ngati kusamvana kuchitika, ma alarm amawonetsa pazenera ndikuwonetsa zomwe mkanganowu ndi.

Dongosolo la hydraulic

Kaonekedwe

1.Oil tank idakhazikitsidwa dongosolo lozizira lozizira (kuziziritsa ndi kuzizira kwa mafuta, mafuta kutentha pang'ono pang'ono mu maola 24.)

2.Kusintha kwa hydraulic kumatengera dongosolo la cartridge la cartridd

3. Tanki yamafuta imakhala ndi fyuluta ya mpweya kuti mulumikizane ndi kunja kuti muwonetsetse kuti mafuta a hydraulic saipitsidwa.

4. Kulumikizana pakati pa valavu yodzaza ndi thankiyo imagwiritsa ntchito cholumikizira kuti muchepetse kugwedeza kwa thanki yamafuta ndikuthetsa vuto la kutayika kwa mafuta.

5.Kuto wamafuta wamafuta wamagetsi umapangidwa makamaka ndi chitoliro chachitsulo chosawoneka, ndipo njira yayikulu kwambiri yamafuta imasokonekera. Kulumikizana kwa chitoliro kumalumikizidwa ndi Flange Flange momwe angathere. Ndi mtundu wowoneka bwino wowuma kwambiri komanso umathetsa bwino matenda otayira mafuta omwe amachitika chifukwa cha kuwala kosawoneka bwino.