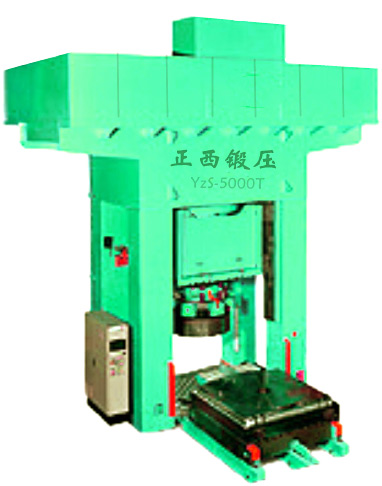

Inopisa kukanganwira hydrauc Press

YZ14 FATER FARE MAHARA Kuregerera Hydraulic Press

Rudzi rwemhando uye ina-column chimiro;

Uchishandisa servo kudzora system, kukwirisa simba kuchengetedza;

Nekukurumidza 400 ~ 1000mm / s, kuumba 50 ~ 200mm / s;

Muviri unonetswa neQ355b zvinyorwa, zvine huremu hwakasimba hwakawanda;

Yakashongedzwa neyekumusoro bolt uye mbiri tsigira kuchengetedza kuchengetedza chishandiso;

Inesarudzo yeAuxiliary Centering mudziyo, Auxiliary punching mudziyo, chaiyo otomatiki kukanganwira, Manipulator uye kumwe kugadzirisa;

Kwahara dzisina kukanganwirwa, dzakakodzera kukanganwira kana kuchena kwakareruka, nekuti kukanganwira mashayi akasiyana-siyana, mhete, makeke, ingots uye mahwendefa uye mahwendefa;

Yakakodzera kukanganwirwa kwekaroni dzakasiyana-siyana simbi, chisimbiso chesimbi, chigadziko chesimbi, simbi yesimbi, simbi isina tsvina uye yakanyanya tembiricha lead;

Inoshandiswa muEerospace, Simba, indasitiri, maindasitiri, kutakura uye kufambisa uye imwe minda;

Precision kufa quingy hydraulic prin

Rudzi rwemhando uye ina-column chimiro, iyo inogona kushandiswa pakupisa kukanganwirwa kana kutonhora kutambanudzwa.

Servo Control System, Micro-kufamba kuumbwa, kumanikidzwa uye chinzvimbo kudzora kurongeka 1%;

Inogadziriswa kumhanya 1 ~ 100mm / s, stepless kumhanya shanduko, yakakwirira kugadzira chokwadi;

Muviri unonetswa neQ355b zvinyorwa, zvine huremu hwakasimba hwakawanda;

Yakashongedzwa neyekumusoro uye yakadzika ejection jekection, ejection cylinder ine sensor yakavakirwa yekudzora chokwadi jekiseni kuumbwa;

Inoshandiswa zvakanyanya mumotokari, machina, michina, petrochemical, boiler kugadzira, erispace, maindapu uye mamwe maindasitiri.

Kuumbwa kweimwe-nguva yePolyhedral zvinhu zvikamu zvinogona kuwedzera zvakanyanya simba rezvikamu, kuderedza mari yekugadzira, uye kusimudzira zvikamu zvakareruka.

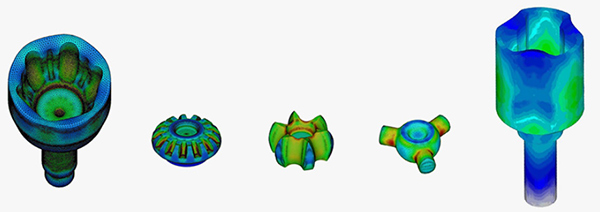

Kupisa kufa kukanganwira hydraulic prin

Chinhu chikuru chekupisa kufa kukanganwirwa ndiko kudzora kwekutsauka kwekushisa pakati pechiumbwa uye chakaumbwa chikamu. Tembiricha yemukati inogona kuiswa kuti ive yakakwirira kupfuura iyo tembiricha yekupisa, isothermal tembiricha yekudzokorora panguva yekukanganisika

Dzvinyiriro Kudzora Kurongeka】 0.1mpa, chinzvimbo chekudzivirira kurongeka

Iyo yekugadzira kumhanya iri kukurumidza, iyo yakaumbwa zvikamu zvine yakakwira dimensional chaiyo chaiyo uye yakaderera mutengo ..

Inesarudzo yemagetsi inopisa, yepakati frequency, yakakwira frequency uye imwe nzira dzekudzidzira, otomatiki kutakura uye kusunungura, kutungamira kunze kwebasa.

Inoshandiswa zvakanyanya mukufambisa, mota, erispace, mararamiro, zvikamu-3c zvemagetsi uye mimwe minda

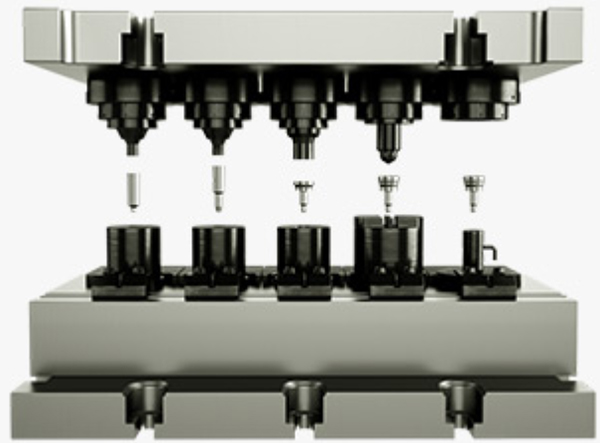

Multi-kutevedza kufa kukanganwira hydraulic prin

Multi-kutevedza kufa kwekunakirwa hydraulic mudumbu remuti anokonzerwa nemidziyo, akakodzera kuumba kukosheswa kwakakosha, uye kunogona kushandiswawo kune imwechete-kutevedza maitiro ekuwedzera;

Servo Control System, yakagadzikana kurova kutonga, kukwirisa kwakakwirira simba;

Framey Typeage Fungisai Marayiture, Kukurumidza Kukanganwira 2 ~ 5 Maitiro, 3 ~ 30s / nguva inokanganwira kumhanya, yakanyanya kukanganwira chokwadi;

Q355B Midziyo Yemanyorero Yevakarongeka, Yakasimba Yese Kuomarara;

Yakasarudzika Range 1 ~ 80mn, Inosarudzika otomatiki Centering mudziyo, otomatiki kurodha uye kusunungura robhoti, kufambisa robhoti uye kumwe kugadzirisa.

Inoshanda kune dzakasiyana-siyana dzinokanganwira zvigadzirwa zvine maumbirwo akareruka uye akarongeka;

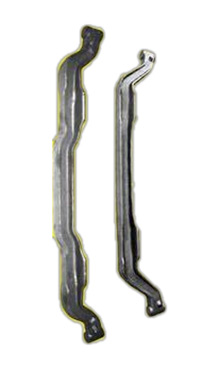

Diki shaft, rin'i, keke, ingot, ndiro, sleeve, kubereka kugadzirisa;

Kukanganwira Barbon Simbi, Alloy Simbi, Simbi Simbi, Simbi Steel, Simbi Isina Simbi uye Yakanyanya Tembiricha Alloy Alloy Simbi;

Multi-kutungamira kufa anokanganwira hydraulic prin

Iyi nhevedzano yeHydraulic michina yakagadzirwa nechimiro chemafuta, yakagadzirirwa neyemafuta mairi cylinder uye kumberi, kumashure, kuruboshwe, uye simba rakaringana, rine simba rakakura uye nekukasira.

Chimiro chiri nyore, mwero wekushandiswa kwezvinhu zvakakwirira, zvinokosha kazhinji zvakaumbwa pane imwe nguva, uye mutengo wekugadzira wadzikiswa;

Kumhanya 50 ~ 400mm / s, Synchronous Extrusion ne Side cylinder; muviri unonetswa neQ355b zvinyorwa, zvine huremu hwakasimba;

Zvigadzirwa zvakakosha zvekugadzira zvine hunyanzvi uye hapana kukanganwira kufa; uchishandisa servo kudzora system, kukwirisa kwakakwirira simba;

Inoshandiswa kune zvigadzirwa zvakasiyana siyana zvine maumbirwo akaoma uye huwandu hwakawanda;

Inokodzera miviri yakasiyana-siyana, pombi majoini, mugumo majoini, disff shaft pamagungano nezvokufadza;

Yakakodzera kukanganwirwa kabhoni akasiyana-siyana, mhangura, aluminium uye alloy simbi zvigadzirwa;

Inogona kuve yakarongedzwa zvakananga nekupisa manipuling manipulator uye yepakati frequency yekuvona kuti izive zvizere otomatiki kuumbwa;