Nekukura kuri kuramba kuchisimba kwezvinhu zvemhando yepamusoro, kuwedzera kune girazi fiber-yakasimbiswa-kabhoni fiber-yakasarudzika mapurasitiki, beron fiber-yakasarudzika mapurasitiki, etc. yakaonekwa. Carbon fiber yakasimbiswa polymer composite (CFRP) yakaremara uye yakasimba zvinhu zvinoshandiswa kugadzira zvigadzirwa zvakawanda zvatinoshandisa muhupenyu hwedu hwezuva nezuva. Iri izwi rinoshandiswa kurondedzera fiber-yakasimbiswa-yakasimbiswa zvigadzirwa zvinoshandisa carbon fibson seicho chikuru chimiro.

Zviri Mukati:

1. Carbon fiber yakasimbiswa polymer chimiro

2. Iyo nzira yekuumbwa yeCarbon fiber yakasimbiswa mapurasitiki

3. Zvivakwa zveCarbon fiber yakasimbiswa polymer

4. Zvakanakira CFRP

5. Zvakaipa zveCFRP

6. Carbon fiber yakasimbiswa plastiki inoshandisa

Kabhoni fiber yakasimbiswa polymer chimiro

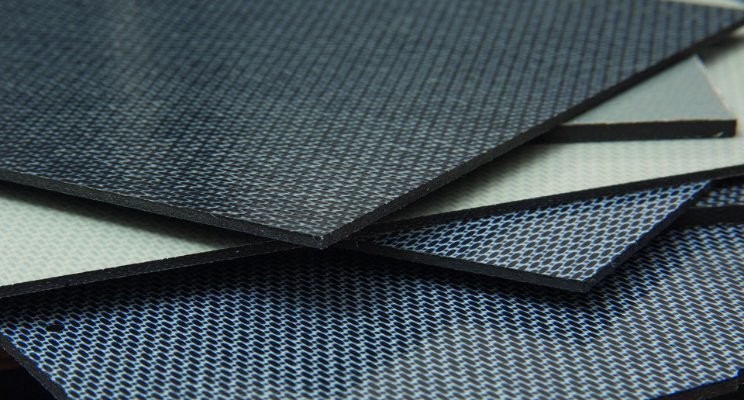

Carbon Fiber yakasimbiswa purasitiki ndeyekuti yakarongedzwa carbon fiber zvinhu mune imwe nzira uye kushandisa yakasungirirwa polymer zvinhu. Iyo dhayamita ye carbon fiber yakanyanyisa kutetepa, anenge manomwe macoroni, asi simba rayo rakanyanya kukwirira.

Iyo yakanyanya kukosha yeCarituent yunivhesiti yeCarbon fiber yakasimbiswa yakasimbiswa yeyakagadzirwa zvinyorwa ndeye carbon fiber fillement. Iyo yekutanga mbichana yezvinyorwa zve carbon filing ndeye preplymer polycrylonitrile (pan), rayon, kana petroleum pitch. Iyo kabhoni mafaira anozoitwa mune carbon fiber machira nemakemikari uye maitiro maitiro eCarbon fiber zvikamu zvikamu.

Iyo yekubatanidza polymer inowanzo kuve iri resmosting resin senge epoxy. Mamwe maThemosets kana Thermoplastic Polymers dzimwe nguva anoshandiswa, senge polyvinyl acetate kana nylon. Pamusoro peCarbon Fibers, manyadzo anokwanisawo kuve neAramid Q, Ultra-yakakwira molecular uremu polyethylene, aluminium, kana girazi fils. Zvivakwa zveiyo yekupedzisira kabhoni chigadzirwa chigadzirwa chinogona zvakare kukanganiswa nerudzi rwezvekuwedzera zvakaunzwa mukubatanidza matrix.

Iyo nzira yekuumbwa yeCarbon Fiber yakasimbiswa mapurasitiki

Carbon Fiber zvigadzirwa zvinonyanya kusiyana nekuda kwemaitiro akasiyana maitiro. Kune nzira dzakawanda dzekuumba carbon fiber yakasimbiswa polymer zvinhu.

1. Nzira yeruoko-kumusoro

Yakakamurwa nenzira yakaoma (pre-yakagadzirirwa shopu) uye nzira nyoro (fiber mucheka uye resin glued kushandisa). Ruoko raigara rwunoshandiswawo kugadzirira mapepa ekushandisa muzvikamu zvechipiri zvekuumba maitiro akadai sekumanikidza kuumba. Iyi nzira ndeyokuti mashizha emachira emakaroni anovharirwa pane choumbwa kuumba chigadzirwa chekupedzisira. Simba uye Smoffness Properties yezvinyorwa zvinokonzerwa zvinogadziriswa nekusarudza kuwirirana uye kurira kwemachira. Iyo mold inozadzwa neye epoxy uye yakarapwa nekupisa kana mweya. Iyi nzira yekugadzira inowanzoshandiswa kune isina-yakamanikidzwa, senge injini inovhara.

2. Vacuum fomu yekugadzira nzira

Kune iyo yakareruka prepreg, inodikanwa kushandisa kumanikidzwa kuburikidza neimwe nzira yekuita kuti ive pedyo neyekuumbwa uye kuporesa uye kuumba tembiricha uye kumanikidzwa. Iyo vacuum bhegi nzira inoshandisa pombi yevacuum kuti ibve mukati mehomwe yekugadzira iyo yekugadzira bhegi kuti idzvanywe pakati pebhegi uye kuumbwa kunoumba kuti zvinhu zvive zvepedyo zviri pedyo neumbwa.

Pahwaro hweVaCuum Bhegi nzira, iyo vacuum bhegi-autoclave yekugadzira nzira yakatorwa gare gare. Autoclaves inopa zvakanyanyisa kudzvinyirira uye kupisa kurapa chikamu (panzvimbo yemupendero wezvakasikwa) pane vacuum bhegi-chete nzira. Chikamu chakadai chine chimiro chakaomarara, chiri nani chinobvisa mhepo mabhuru emhepo (bubbles ichakanganisa zvikuru simba rechikamu), uye hunhu hwese hwakakwira. Muchokwadi, maitiro eVaPuum Bhegi akafanana neiyo yefoni mbozha mafirimu ekunamatira. Kubvisa Mhepo Bubbles ibasa rakakura.

3. Kudzvinyirira Kuumba nzira

Kudzvinyirira Kuumbainzira inoumba iyo inokodzera kugadzirwa kukuru uye kugadzirwa kwakawanda. Molds anowanzogadzirwa nezvikamu zvepamusoro uye zvakaderera, izvo zvatinodaidza vanhurume kuumbwa uye chikara chakaumbwa. Maitiro ekuumbwa anofanirwa kugadzirwa nemapuranga muzvikamu zvesimbi, uye pasi pekudzvinyirira uye nekumanikidzwa, kuyerera kwemuchadenga, uye kuchizadza mold. Nekudaro, nzira iyi ine yakakwirira yekutanga mutengo pane iyo yapfuura, sezvo iyo mold inoda yakanyanya-chaiyo-chaiyo cnc machining.

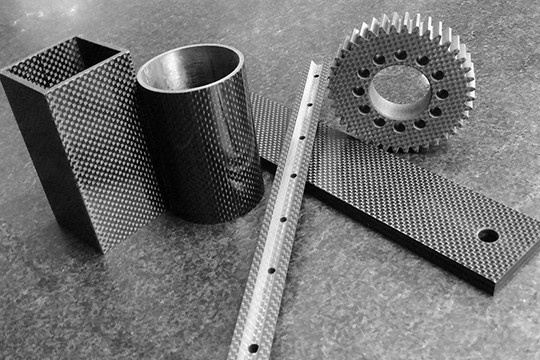

4. Kudonha kuumbwa

Zvikamu zvine mwero akaomarara kana muchimiro chemuviri wekuchinja, chirahwe chemhepo chinogona kushandiswa kuita chikamu nekumonera mudziyo pane mandrel kana musimboti. Mushure mekunge mhepo yakakwana kurapa uye kubvisa mandrel. Semuenzaniso, tubular nemaoko akabatanidzwa akashandiswa mukumiswa masisitimu anogona kuitwa uchishandisa nzira iyi.

5. Resin Resin kuumbwa

Resin kuendesa kuumba (RTM) inzira yakakurumbira yekuumba. Matanho ayo ekutanga ndeaya:

1. Isa iyo yakagadzirirwa kabhoni kabhoni fiber mucheka muumbi uye kuvhara iyo mold.

2.

Zvivakwa zve carbon fiber yakasimbiswa polymer

(1) Simba rakakwirira uye rakanakisa elasticity.

Simba raiye (iro ratove, ratio remamiriro ekunze kune density) ye carbon fiber ndeye 6 times iyo yesimbi uye gumi nematanhatu ayo ealuminium. Iyo chaiyo modulus (iyo ndeyekuti, iyo ratio yewechidiki yechidiki kuti dentity, ichi chiratidzo chekushandurwa kwechinhu) chinopfuura katatu nguva iyo yesimbi kana aluminium.

Ine simba rakakwirira chaizvo, inogona kutakura mutoro wakakura wekushanda. Kudzvanywa kwayo kwakakwana kunogona kusvika 350 kg / cm2. Uye zvakare, inoenderana uye inoenderana kupfuura yakachena f-4 uye neiyo bread.

(2) Kuneta kwakanaka kuramba uye kupfeka kuramba.

Kupokana kwaro kuneta kwakanyanya kupfuura iyo ye epoxy resin uye yakakwirira kupfuura iyo yezvinhu zvesimbi. Graphite Fibers vanozvifunga uye vane diki diki yekukakavara. Kuwanda kwekupfeka ndeye 5-10 times madiki pane iyo yeiyo general asbestos zvigadzirwa kana F-4 braids.

.

Carbon fiber yakasimbiswa mapurasitiki ine yakanaka yekuwaridza kusawirirana, uye kupisa kunogadzirwa nekukakavara kunoraswa nyore nyore. Iyo yemukati haisi nyore kunyanyisa uye kuchengeta kupisa uye inogona kushandiswa seyakaiswa chisimba chisimbiso. Mumhepo, inogona kushanda zvine simba mune tembiricha yekudziya ye -120 ~ 350 ° c. Nekuderedzwa kweAlkali simbi zvemukati muCarbon fiber, iyo tembiricha yebasa inogona kuwedzera kuwedzerwa. Mugesi Inert, tembiricha yayo inochinja inogona kusvika pa000 CL, uye inogona kutsungirira shanduko yakapinza mukutonhora uye kupisa.

(4) Kubata kwakanaka kwakanaka.

Izvo hazvisi nyore kuyananisa kana kupfita, uye zvakare yakanakisa zvinhu zvekudzikisira kweshoko uye kuderedzwa ruzha.

Zvakanakira CFRP

1. Right uremu

Tsika yechinyakare fiber yakasimbiswa plastics plastics yegirazi fils uye 70% girazi fibers (girazi uremu / huwandu hwehuwandu hwe0,065 pround per cubic inch. A CFRP muchinjikwa neiyo SEAT 70% Fiber uremu kazhinji ine density ye0,055 mapaundi ebhiti inch inch.

2. Yakakwirira Simba

Kunyangwe carbon fiber yakasimbiswa polymers akarara, cfrp composites ane simba rakakwira uye rakanyanya kuomarara pane uremu hwegirazi kupfuura girazi fiber carositi. Kuenzaniswa nezvinhu zvesimbi, iyi mukana ndeye pachena.

Zvinokuvadza zveCFRP

1. Yakakwirira mutengo

Mutengo wekugadzira weCarbon fiber akasimbisa mapurasitiki anorambidza. Carbon Fiber Mitengo inogona kusiyana zvakanyanya zvichienderana nemamiriro epazvino emusika (kupa uye kudiwa), mhando yekabhoni fiber (Aerospace vs. Pamunun'una-found hwaro, mhandara carbon fiber inogona kuve mashanu kusvika ku25 zvakapetwa zvishoma kudhura kupfuura girazi fiber. Uyu musiyano wacho wakatonyanya kukura kana uchienzanisa simbi kune cfrp.

2. Kubata

Iyi ndiyo mukana uye kusagadzikana kwe carbon fiber composite zvinhu. Zvinoenderana nesarudzo. Carbon fibers inonyanya kuitisa uye magirazi mafaira ari kuongorora. Zvigadzirwa zvakawanda zvinoshandisa fiberglass pane kabhoni fiber kana simbi nekuti izvo zvinoda kutaridzika kwekunzwa. Mukugadzirwa kwezvinhu zvekushandisa, zvigadzirwa zvakawanda zvinoda kushandiswa kwegirazi.

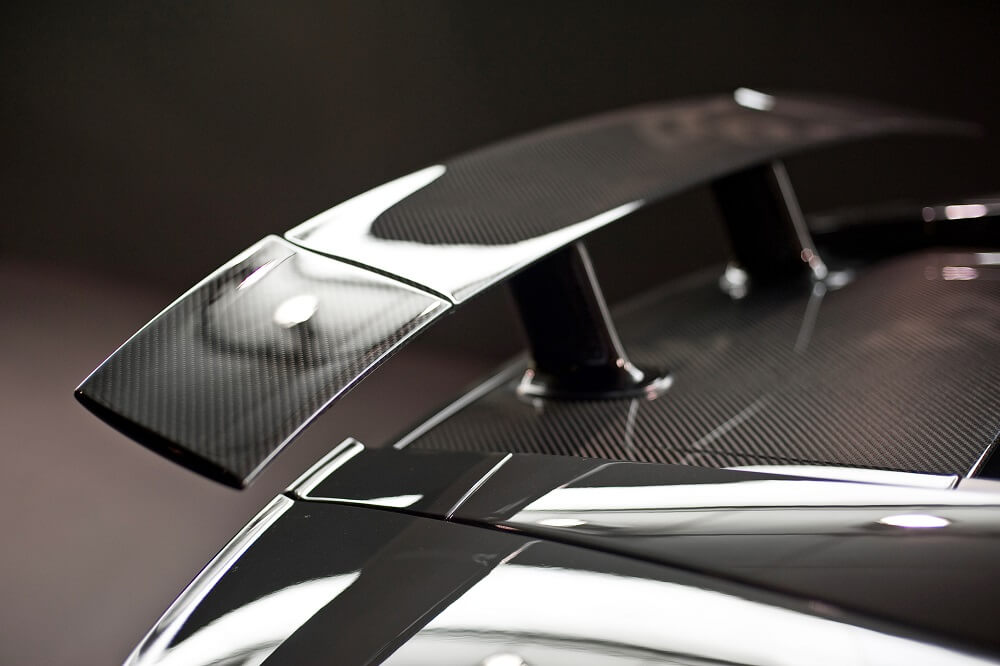

Carbon fiber yakasimbiswa epurasitiki inoshandisa

Zvikumbiro zveCarbon fiber yakasimbiswa polymer zvakakura muhupenyu, kubva kuzvikamu zvemitambo kuenda kumauto.

(1)sekurongedza kurongedza

Carbon Fiber yakasimbiswa yePTFE zvinhu inogona kuitwa mune corrosion-inopesana, kupfeka-kupfeka, uye yakanyanya-kupisa-mhere mhete kana kurongedza. Kana ichishandiswa kuiswa kuLatic kuisirwa, hupenyu hwebasa hwanyina kwenguva refu, kanopfuura koreji koreba kupfuura iyo yeiyo general emafuta-yakarongedzwa asbestos packing. Inogona kuchengetedza kuita kwemisimboti pasi pekutakura zvinochinja uye nekukurumidza kutonhora uye nekukurumidza kupisa. Uye sezvo izvo zvinyorwa zvisina kana zvinhu zvinodzora, hapana kukanganisa kunoitika pane simbi.

(2)Sezvinoita zvikamu

Kushandisa zvivakwa zvekuzvininipisa, zvinogona kushandiswa semabhizimusi, magiya, uye mhete dze piston dzezvinangwa zvakakosha. Yakadai semafuta-emafuta emafuta emidziyo yekuridza midziyo uye maGeals-emafuta emhando yekudzora emagetsi.

. Yakatanga kushandiswa mucheki yekugadzira kuti ideredze uremu hwendege uye nekuvandudza kubhururuka kwekufara. Izvo zvinoshandiswawo mumakemikari, peturu, simba emagetsi, michina, uye mamwe maindasitiri seyakaomarara kana kudzoreredza chisimbiso chezvisimbiso zvemukati.

Zhengxi inyanzviHydraulic Press Factory muChina, kupa yakakwirira-quliatycomposite hydraulic prinyekuumba zvigadzirwa zveCFRP.

Kutumira Nguva: May-25-2023