Kuregererwa izita rinoungana rekuregerera nekutsika. Iyo inzira yekugadzira yekugadzira inoshandisa nyundo, uye punch, uye punch yemuchina kana kuumbwa kuti iite yakanamirwa pane yakakonzeresa deform deform kuti uwane zvikamu zvechimiro chinodiwa uye saizi.

Chii chinokosheswa

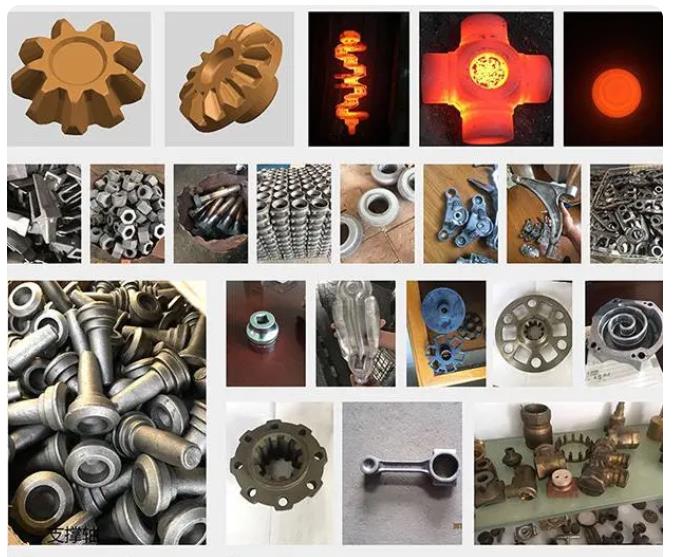

Panguva yekuregerera, iyo yese isina chinhu inoenderana nehurongwa hwepurasitiki hwakakosha uye huwandu hwakawanda hwekuyerera kwepurasitiki. Mukutamba kwemitambo, iyo isina chinhu inonyanya kuumbwa nekuchinja nzvimbo yenzvimbo yenzvimbo yega yega, uye hapana mapurasitiki kuyerera pamusoro penzvimbo huru mukati maro. Kuregererwa kunonyanya kushandiswa kugadzirisa zvikamu zvesimbi. Inogona zvakare kushandiswa kugadzirisa vamwe vasingabati, senge mapurasitiki enyunguzi, rabha, ceramic blanks, zvidhinha, uye kuumbwa kwezvinhu zvevamari.

Kutenderera, kudhirowa, etc. Mukukosheswa uye metallurgical indasitiri ese maviri epurasitiki kana kumanikidza kugadzirisa. Nekudaro, kukamba kunonyanya kushandiswa kugadzira zvikamu zvesimbi, nepo kuhukura uye kudhirowa kunonyanya kushandiswa kugadzira zvinhu zvakajairika-midziyo, mitsetse, mapepa, uye waya.

Kugadziriswa kwekukosheswa

Kukanganwira kunonyanya kuiswa maererano nenzira yekuumba nzira uye kushambadzira tembiricha. Zvinoenderana nenzira yekuumba, kukambaira kunogona kukamurwa kuita mapoka maviri: kukanganwika uye kusimuka. Zvinoenderana neiyo yekushongedza tembiricha, kukambaira kunogona kukamurwa mukupisa zvinokambaira, kutonhora kukanganwika, kunoparadza, uye zvinotaurwa neatothermal, etc.

1. Kupisa kukamba

Kunopisa kukanganwira kunokosheswa kunoitwa pamusoro peanodziya tembiricha yesimbi. Kuwedzera tembiricha kunogona kuvandudza plasticity yesimbi, iyo inobatsira kuvandudza mhando yemukati yeiyo basa rekushanda uye uchiita kuti zvisingakwanisi kupwanya. Tembiricha yakakwira inogona zvakare kuderedza iyo deformation kuramba yesimbi uye kuderedza tonnage yekudiwaKukanganwira Machina. Nekudaro, kune zvakawanda zvinopisa zvinokambaira maitiro, preciece workisii murombo, uye nzvimbo yacho haina kutsvedza. Uye kukangamirwa kwakanyorwa kune oxidation, kuderera, uye kukuvadza kunopisa. Kana basa rekushanda rakakura uye rakakura, zvinyorwa zvine simba rakanyanya uye rakadzika bhuroka mahombekombe ekumwe, kudhirowa kabhodhi yekaruru simbi, nezvimwewo, uye zvinokambaira zvinoshandiswa.

Kazhinji inoshandiswa inopisa yekuregerera tembiricha ndeye: Carbon Steel 800 ~ 1250 ℃; Alloy yakarongedzwa simbi 850 ~ 1150 ℃; kumhanya kwakakwirira simbi 900 ~ 1100 ℃; inowanzo shandiswa aluminium Alloy 380 ~ 500 ℃; Alloy 850 ~ 1000 ℃; ndarira 700 ~ 900 ℃.

2. Kutonhora kukanganwirwa

Kutonhora kukanganwira kunokosheswa kunoitwa pasi pesimbi yekudzokorora kwesimbi. Kazhinji kutaura, kutonhora kukanganwira kunoreva kukanganwisa kupisa kwemakamuri.

Mabasa ebasa akaumbwa nekutonhora kukanganwirwa pamhepo tembiricha ane chimiro chakakwirira uye chakazara kurongeka, nzvimbo dzakatsiga, mashoma ekugadzirisa matanho, uye zviri nyore kugadzirwa kwekugadzira. Zvikamu zvakawanda zvinotonhora uye zvinotonhora zvakatemwa zvinogona kushandiswa zvakanyatsoshandiswa sezvikamu kana zvigadzirwa pasina zvinodiwa nemachina. Nekudaro, panguva yekutonhora, nekuda kwesimbi yakaderera yesimbi, kupaza kuri nyore kuitika panguva yekuparadza kwakakura, kunoda kufarirwa nemana anokanganwira michina.

3. Kunodziya kukanganisika

Kuregererwa pane tembiricha yakakwira kupfuura yakajairwa tembiricha asi isingapfuure iyo yekudziya tembiricha inonzi inodziya inokosheswa. Iyo simbi inodiwa, uye kupisa kupisa kwakadzika kwazvo pane zvekuparadza zvinopisa. ROPA RONESESESESESWA INOGADZIRA KUTI UCHENJERI

4. Isothermal aukanganwire

Isothermal kukanganwirwa kunoita kuti tembiricha isina chinhu inogara ichiripo panguva yese yekugadzira. Pasothermal kukanganisirwa ndeye kushandisa zvizere mapurasitiki epamusoro weimwe simbi pane imwe tembiricha kana kuti uwane zvivakwa uye zvivakwa. ISOHORAMAL Rake rinoda kuchengeta chiumbwa uye zvinhu zvakashata pakudziya nguva dzose, izvo zvinoda mutengo wakakwira uye zvinongoshandiswa chete pakukanganisika kwakakosha, sekuti muviri wakanyanya.

Hunhu hwekukanganwira

Kuregererwa kunogona kuchinja chimiro chesimbi uye kugadzirisa zvivakwa zvesimbi. Mushure mekunge ingot inopisa, kusununguka kwekutanga, mapores, micro-micro-microccise, etcc. mune iyo yekukanda mamiriro anofananidzirwa kana kuiswa. Madhiramu ekutanga akaputswa, achigadzira iyo logins yakanaka. Panguva imwecheteyo, iyo yekutanga carbide segregation uye kugovera kusagoverwa kunoshandurwa. Gadzira iyo yunifomu, kuti uwane faindi yeiyo yakakosheswa, yunifomu, yakanaka, ine maitiro akanaka ese, uye akavimbika mukushandisa. Mushure mekuregererwa kuchikanganiswa nekupisa kukamba, simbi ine chimiro chakakura. Mushure mekutonhora kukanganwirwa deformation, iyo simbi crystal inova yakarongeka.

Kuregerera ndiko kuita kuti simbi inoyerera yakanganisa kuumba basa rekushanda kweiyo chimiro chaunoda. Iyo vhoriyamu yesimbi haina kuchinja mushure mekuyerera kwepurasitiki kunoitika nekuda kwesimba rekunze, uye simbi inogara ichiyerera kusvika kune chikamu nehanya kushoma. Mukugadzira, chimiro cheiyo basa rekushanda zvinowanzotongwa zvinoenderana nemitemo iyi kuzadzisa deformations dzakadai sekurema, elongation, kukotama, uye kudhirowa zvakadzika.

Saizi yeiyo yakagadzirirwa basa rekushanda yakarurama uye inokodzera kuronga kugadzirwa kukuru. Zvidimbu zveMold kugadzira mumashandisirwo akadai sekukanganwira, kuumbwa, uye kusimuka kwakarurama uye kugadzikana. Kubudirira-kugona kukanganwira michina uye otomatiki kukanganwira mitsara yekugadzira kunogona kushandiswa kuronga kwakasiyana siyana kana kugadzirwa kwakawanda.

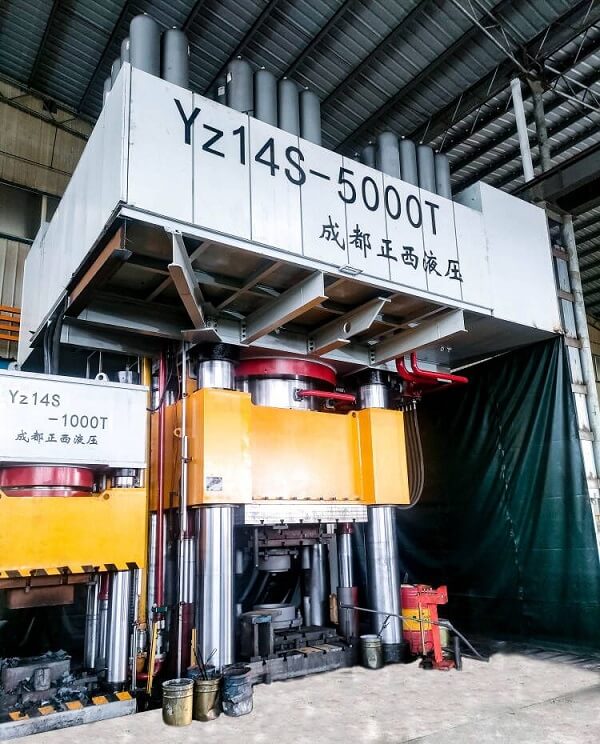

Inowanzo shandiswa kukanganwirwa michina inosanganisira aregerera nyundo,Hydraulic michina, uye michina michina. Iyo inokanganwira nyundo ine chinomhanyisa chakanakira kukurudzira, izvo zvinobatsira kupurasitiki kuyerera kwesimbi, asi ichabereka vibrate. Iyo hydrautic yemushini inoshandisa kusagadzikana kweiyo, iyo inobatsira kukanganisika kuburikidza nesimbi uye nekuvandudza chimiro. Basa racho rakasimba, asi kubereka kwakaderera. Iyo mechenical mechina ine yakasarudzika sitiroko uye iri nyore kushandisa mechanization uye automation.

Development maitiro ekukanganwira tekinoroji

1) Kuti uvandudze mhando dzemhando yepamusoro, kunyanya kuvandudza zvivakwa zvavo zvekugadzira (simba, kupururudza, kuoma, kusimba, kusasimba simba) uye kuvimbika.

Izvi zvinoda kushanda zviri nani kwedzidziso yepurasitiki yekushatirisa yesimbi. Nyorera zvigadzirwa zvine hunhu huri nani, sekurapwa-kwakabatwa simbi uye vacuum-yakanyungudika simbi. Ita pre-pre-kukanganwira nekudzivirira kupisa kurapwa nenzira kwayo. Kuwedzera kwakasimba uye kwakawandisa kusingafadzi kuongororwa kwenhengo dzakamiswa.

2) Kuwedzera kukudziridza precides kukanganwira uye kunyatsogadzira tampulogy. Kucheka kusiri kwekucheka ndiyo yakanyanya kukosha uye kutungamira kweinhandare yemichina kuti uvandudze zvinhu zvinoshandiswa, kugadzirisa mari yebasa, uye kuderedza kushandiswa kwesimba. Iko kuvandudzwa kwesiri-oxidative kupisa kwekukosheswa, uye nekuomerwa kwakanyanya, kupfeka, hupenyu hwekurapa, zvichaenderana nekunyorwa kwekunyorwa kwekunyatso kukanganisika uye kunyatsoitika kusimuka.

3. Pasi pekugadzirwa kwakanyatsogadzirwa, kubereka kwebasa kwakavandudzwa uye kurasikirwa kwemitengo kunoderedzwa.

4) Gadzira inochinjika inokanganisika kugadzira masisitimu (kushandisa tekinoroji yeboka, nekukurumidza kufa, nezvimwewo). Izvi zvinogonesa akawanda-akasiyana-siyana, zvidiki-batch kukoshesa kugadzirwa kuti ushandise zvakanyanyisa-kugona uye zvakanyanyisa kukanganisika zvishandiso kana mitsara yekugadzira. Ita kuti kubereka kwaro uye hupfumi padyo nedanho rekugadzira misa.

5) Gadzira zvinhu zvitsva, zvakadai sekukosheswa kugadzirisa nzira dzepfuma dzepfuma Gadzira matekinoroji akadai seyekumusoro-shuwa kugadzira, yakakwirira-simba kugadzira, uye yemukati-kumanikidza-kudzvinyirira.

Kutumira Nguva: Kukadzi-04-2024