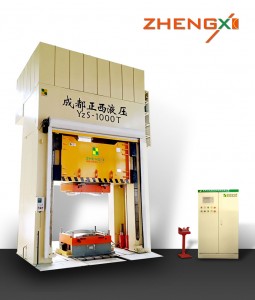

BMC SMC Manhole oo Mashiin Mashiin

Zhengxi smc hydralic Press waxaa sidoo kale loo yaqaan 'hydralic composites', waxaa lagu dabaqayaa caaryada isku-dhafka ah ee waxyaabaha ku jira SMC, BMC, FRP, FRP, GRP, GRP, GRP, GRP, GRP. SMC-dayada SMC waxay sameysay saxaafadda oo riix Proces Partners Adagga Soosaarka Warshadaha Supiouace-ka ah ee Warshadaha Persers, iyo sidoo kale dayactirka iyo isku-darka xulashooyinka. Waxaan soo bandhigayaa Kastamyo cusub oo ah saxaafadda cusub ee hayada ah, Zhengxi aslo waxay bixisaa liis dhameystiran oo ku saabsan dayactirka iyo kor u qaadista xulashooyinka isku-darka cadaadiska ee jira ee dhammaantood sameeya iyo moodooyinka. Cadaadiskayaga wasakhda ah ee khafiifka ah ayaa loo isticmaalaa in lagu soo saaro noocyo kala duwan oo asaasi ah oo ku saabsan baabuurka, aerospace, warshadaha iwm.

Astaamaha mashiinka

Eatit waxaa inta badan loo isticmaalaa qaab-dhismeedka is-dhexgalka ah ee balaastigga heerkul (FRP) balaastigyada iyo waxyaabaha heerkulka loo yaqaan 'themontoplastic'. Ku habboon sameynta SMC, BMC, DMC, GMT iyo bullaacadaha kale iyo go'yaal.

Nidaamka xdralic nidaamka waxaa lagu rakibay dusha sare ee lagu rakibo masraxa dayactirka, bey'adda u fiican, dhawaqa hoose iyo dayactir fudud.

Mullult-marxaladda xawaaraha xawaaraha xawaaraha ee xawaaraha ah, waqti macquul ah oo la keydiyey.

Orninth howsha caaryada caaryada funaanadda ee si gaaqada ah ee furitaanka, ku habboon badeecadaha sare.

Jawaabta Nidaamka Nidaamka Nidaamka, Tirada kontaroolka tirooyinka.

Sawirka goobta

Codsiyada

Mashiinkan wuxuu inta badan ku habboon yahay inuu ka kooban yahay sheyga ka kooban; Qalabka ayaa leh nidaam wanaagsan oo nidaamsan iyo sax ah oo sare, nolol sare iyo isku halayn sare. Geedi socodka saxaafadda kulul ee la dejinayo Saxaafadda ayaa la kulmay 3 wareeg / wax soo saarka maalinta.

XARUNTA XARUNTA

| JB / T3818-99"Xaaladaha farsamada ee saxaafadda hydralic saxaafadda" |

| GB / T 3766-2001"Shuruudaha guud ee farsamada ee nidaamyada hydraulic" |

| GB5226.1002"Nabdoonaanta mashiinka mashiinka-farsamada iyo qalabka korantada-Qeybta 1: Shuruudaha farsamada guud" |

| GB17120-97"Shuruudaha farsamada mashiinka mashiinnada" |

| Jb9967-99"Xadka qaylada mashiinka mashiinka" |

| JB / T8609-97"Riix mashiinka mashiinnada farsamada" |

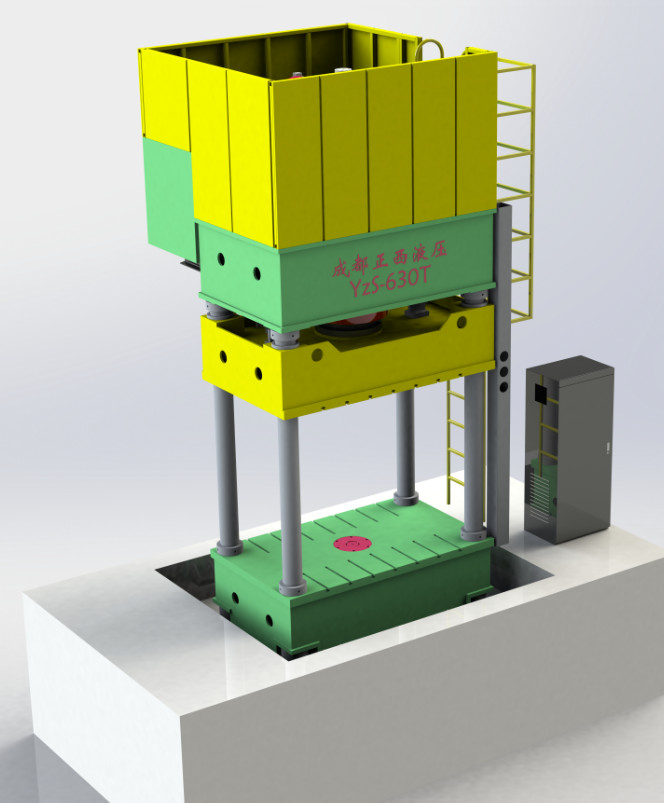

3D sawir

H Nooca Nooca

4 Nooca tiirka

Cabirrada Mashiinka

| Item | Cutub | Yz71-4000t | Yz71-3000t | Yz71-2500t | Yz71-2000t | Yz71-1500t | Yz71-1000t |

| Cadaadis | kN | 40000 | 30000 | 25000 | 20000 | 15000 | 10000 |

| Max. cadaadis dareere ah | Markhaati | 25 | 25 | 25 | 25 | 25 | 25 |

| Maalin iftiin ah | Mm | 3500 | 3200 | 3000 | 2800 | 2800 | 2600 |

| Argagax | Mm | 3000 | 2600 | 2400 | 2200 | 2200 | 2000 |

| Cabbirka Shaxda Shaqada | Mm | 4000 × 3000 | 3500 × 2800 | 3400 * 2800 | 3400 * 2600 | 3400 * 2600 | 3400 * 2600 |

| Dhererka dhulka ka sarreeya | Mm | 12500 | 11800 | 11000 | 9000 | 8000 | 7200 |

| Qoto dheer aasaaska | mm | 2200 | 2000 | 1800 | 1600 | 1500 | 1400 |

| Xawaaraha hoos | Mm / s | 300 | 300 | 300 | 300 | 300 | 300 |

| Xawaaraha shaqada | Mm / s | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 |

| Xawaaraha soo celi | Mm / s | 150 | 150 | 150 | 150 | 150 | 150 |

| Wadarta awoodda | kW | 175 | 130 | 120 | 100 | 90 | 60 |

Jirka weyn

Naqshadeynta mashiinka oo dhami wuxuu qaatay qaabeynta kombiyuutarka kombiyuutarka iyo falanqaynta aaladda gawaadhi. Xoogga iyo adkaanta qalabka waa wanaagsan yihiin, muuqaalkuna waa wanaagsan yahay. Dhammaan qaybo ka mid ah qaybaha mashiinka ah ee jirka ka mid ah ayaa ku habeeya tayo sare oo bir ah oo bir ah Q345b oo bir bir ah, oo lagu qurxiyo kaarboon dioxide si loo hubiyo tayada alxanka.

Dhululubo

| Qaybo | Fcunidda |

| Foosto dhululubo |

|

| Piston Rod |

|

| Shaaar | Qaadashada Jabaan caanka ah ee Jabaan |

| Qalab | Hanuuniyey by perper perper, caabbinta wanaagsan, hubinta hawlgal muddada dheer ah ee dhululubada |

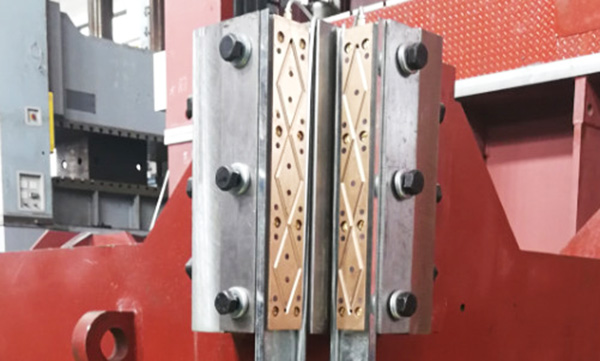

Tiir

Tilmaamaha hage (tiirarka) ayaa laga sameyn doonaaC45 bir kululoo aad yeelato dhumuc adag oo kala go 'ah 0.0mm. Oo samee daaweyn adag oo xanaaq badan. Gacmaha hagida waxay qaadataa hagaha hagaha naxaasta ah, kaasoo aad u adkaysta oo hagaajinaya xasilloonida mashiinka

Nidaamka servo

1.Servo Nidaamka Nidaamka

2.Servo Nidaamka Nidaamka

| Magac | Mkol | Pictap | Adigtoon |

| Ul | Siemens |

| Nolosha batoonka ayaa si adag loo tijaabiyaa, oo waxna lagu dhaawaco iyadoo la riixayo 1 milyan jeer. Shaashadda iyo cilad ciladdu caawiso, sharax howlaha shaashadda, sharax qalabka digniinta mashiinka, iyo ka caawi adeegsadayaasha inay si dhakhso leh u bartaan isticmaalka mashiinka

|

| Magac | Mkol | Pictap | Adigtoon |

| Plc | Siemens |

| Khadka helitaanka Taliyaha Elektiroonigga ah ayaa si madaxbanaan loo maareeyaa, iyadoo leh awood ku-meel-gaar ah oo faragelin ah Xakamaynta dijitaalka ah ee loo yaqaan 'spedo' iyo is dhexgalka iyadoo wata wadista |

| Darawalka Servo

| Ysasawa |

| Guud ahaan bodcaritor si buuxda ayuu u casriyeysan yahay, oo uuna u yeeraa Suufaitor ballaaran oo laqabsashada heerkulka iyo nolosha adeegga dhaadheer ayaa la istcimaalaa, noloshuna nolosha ayaa la kordhiyaa 4 jeer;

Jawaabta 50mpa waa 50mms, cadaadiska hoostiisa waa 1.5kgf, waqtiga gargaarka cadaadiska ayaa ah 60ms, iyo isbadalka cadaadiska ayaa ah 0.5kgf.

|

| Serso matoor

| Taxanaha wajiga |

| Naqshadeynta jilitaanka waxaa sameeya software ansoft, oo waxqabadka elektaroonigga ah ayaa ka sareeya; iyadoo la adeegsanayo wax qabad aad u sarreeya, oo ah birta birta ayaa yar, hufnaantuna way ka badan tahay, kuleylka ayaa ka yar;

|

3. Fomactors of Nidaamka SPONE

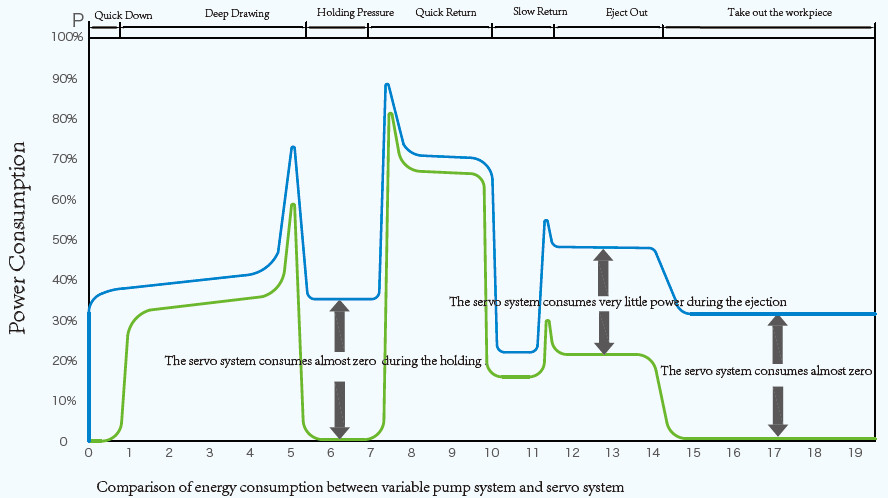

Keydinta tamarta

Marka la barbar dhigo nidaamka matoorka ee caadiga ah ee matoorka, nidaamka matoorka xawaaraha ee xawaaraha xawaaraha ee 'Strepless Pastress' ee Stepless Pasts MotoT MotoT, oo isku-haynta astaamaha cadaadiska saliida ee saliida, kaas oo keena suurtagalnimada tamarta badan ee kaydinta tamarta, iyo tamartaHeerka keydinta ayaa gaari kara ilaa 30% -80%.

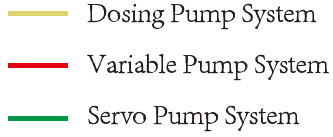

Waxqabad leh

Xawaaraha jawaabta waa mid dhakhso badan oo jawaabtu waxay u gaaban tahay 20ms, oo hagaajinaysa xawaaraha jawaabta ee nidaamka hydralic.

Sax

Xawaaraha degdega ah wuxuu dammaanad qaadayaa furitaanka iyo xiritaanka sax ahaanta, saxsanaanta booska ayaa gaari kara 0.1mm, iyo saxsanaanta booska gaarka ah ee shaqada ayaa gaari kara± 0.01mm.

Moodhka saxda ah ee PID-sareeya,-jawaab-celinta PID-da-pid Algorithm-ka ayaa hubiya cadaadiska cadaadiska ee xasilloonida iyo isbadalada cadaadiska ee ka yar± 0.5 bar, Hagaajinta tayada wax soo saarka.

Ilaalinta deegaanka

Sanqafka: Celcelis ahaan buuqa nidaamka hydraulic servo waa 15-20 dB ka hooseysa kan taranka asalka ah ee la beddelay.

Heerkulka: Kadib nidaamka SPO-da ayaa la istcimaalaa, heerkulka saliida ee hydraulic waa mid hoos udhaca guud ahaan, taas oo xoojineysa nolosha shaabadaasi ama waxay yareysaa awoodda qaboojiyaha.

Qalabka badbaadada

Ilaalada korantada ee korantada ee korantada hore iyo gadaal

Slide qufulka TDC

Laba qalliin oo istaaga ah

Shuruucda caymiska taageerada ee hydralic

Badbaadinta xad-dhaafka ah: valve block

Alaarmiga heerka dareeraha ah: heerka saliida

Digniinta heerkulka saliida

Qayb kasta oo korantada ayaa leh difaac xad dhaaf ah

Beeraha badbaadada

Nuqulada qufulka waxaa loo bixiyaa qaybo la dhaqaajin karo

Dhammaan ficilka saxaafadda waxay leeyihiin howlo nabadgelyo ah, tusaale ahaan la dhaqaaqi karo oo la dhaqaaqi karo ma shaqeyn doono haddii barkinta lagu soo celiyo booska koowaad. Slide ma riixi karto markii la dhaqaaqi karo oo la dhaqaaqi karo. Markay hawlgallo isku dhacu dhacaan, qaylo-dhaan digniin muujineysa shaashadda taabashada oo tus waxa isku dhaca.

Nidaamka hydralic

Tan waxaa lagu dejiyay aaladda filterka ee qaboojinta qaboojinta ee qaboojinta (qalabka loo yaqaan 'plate-ka lagu qaboojiyo biyo-qaboojinta biyaha, qaboojinta iyada oo la wareejinayo biyaha, heerkulka saliida, in mashiinka si isdaba joog ah u riixayo 24 saac.)

2. Nidaamka hydralic-ka wuxuu qaadanayaa nidaamka xakamaynta isku-dhafan ee kartoonada oo leh xawaare xawaare dhakhso leh iyo hufnaan sare.

3. Haanta saliida waxay ku qalabaysan tahay shaandhada hawada si ay ula xiriiraan bannaanka si loo hubiyo in saliida biyo-baxa uusan wasakheynin.

4. Xiriirka u dhexeeya wanaagga buuxinta iyo haanta shidaalka waxay isticmaashaa kala-goyn dabacsan si looga hortago gariirku inuu u gudbiyo haanta shidaalka oo gebi ahaanba xalliso dhibaatada daadashada saliida.