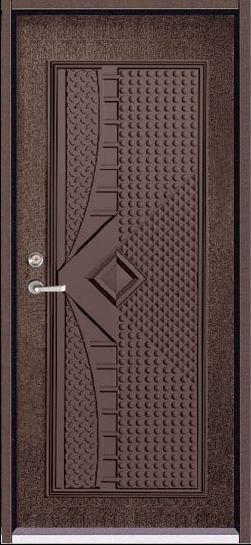

Albaabka ka-hortagga tuugada

Kiis shirkadeed

Isticmaal

Mashiinkan wuxuu inta badan ku habboon yahay albaabka birta ah. Qalabka ayaa leh nidaam wanaagsan oo nidaamsan iyo sax ah oo sare, nolol sare iyo isku halayn sare. Geedi socodka embos-ka ee qaybaha birta ee birta ayaa buuxiya 3 wareeg / wax soo saarka maalinta ..

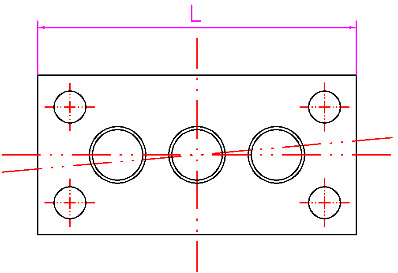

Cabirrada Mashiinka

| Magac | Cutub | Qiimayn | Qiimayn | Qiimayn | Qiimayn | |

| Nooc |

| Yz91-4000t | Yz91-3600t | Yz91-2500t | Yz91-1500t | |

| Ciidamada dhululubada ugu weyn | KN | 40000 | 36000 | 25000 | 15000 | |

| Maalin iftiin ah | mm | 500 | 500 | 500 | 500 | |

| Stroke Minelorder | mm | 400 | 400 | 400 | 400 | |

| Dhululullurder Qyi. | / | 6 | 6 | 6 | 6 | |

| Cabirka miiska

| LR | mm | 1600 | 1600 | 1400 | 1400 |

| FB | mm | 2600 | 2600 | 2400 | 2400 | |

| Xawaaraha slider | Hoose | mm / s | 80-120 | 80-120 | 80-120 | 80-120 |

| Soo celin | mm / s | 100 | 100 | 100 | 100 | |

| Shaqo | mm / s | 10-15 | 10-15 | 10-15 | 10-15 | |

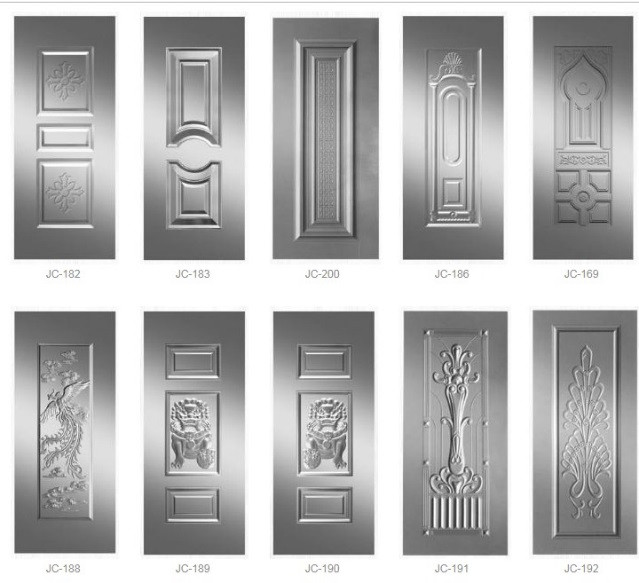

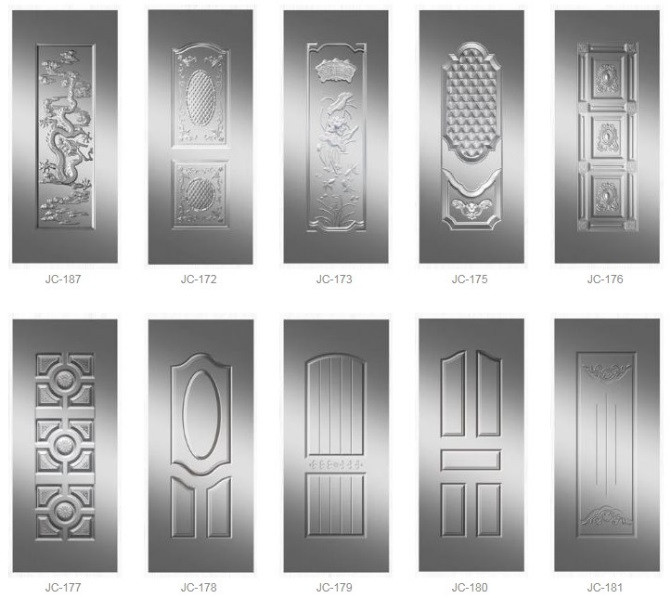

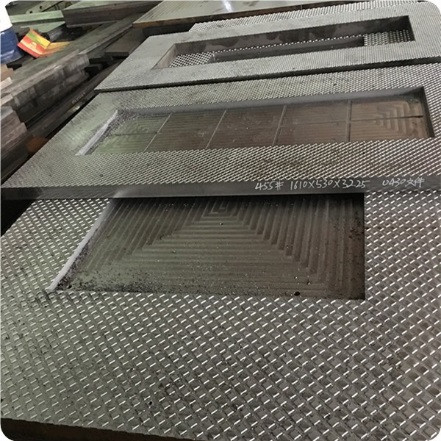

Albaabka caaryada iyo qaababka

Waxaan ku siin karnaa qaabab kala duwan macaamiisha si ay u doortaan, waxaan ku siin karnaa wasakhooyinka. Caaryada caaryada waxaa lagu tijaabin doonaa warshadeena.

Caarku wuxuu ka kooban yahay 1 set oo caaryo ah iyo noocyo badan oo boodhka caaryada ah, macaamilku wuxuu sameyn karaa qaab kala duwan, wuxuuna u baahan karaa oo keliya inuu iibsado 1 set oo caaryada ah.

Qalabka badbaadada

Ilaalada korantada ee korantada ee korantada hore iyo gadaal

Slide qufulka TDC

Laba qalliin oo istaaga ah

Shuruucda caymiska taageerada ee hydralic

Badbaadinta xad-dhaafka ah: valve block

Alaarmiga heerka dareeraha ah: heerka saliida

Digniinta heerkulka saliida

Qayb kasta oo korantada ayaa leh difaac xad dhaaf ah

Beeraha badbaadada

Nuqulada qufulka waxaa loo bixiyaa qaybo la dhaqaajin karo

Dhammaan ficilka saxaafadda waxay leeyihiin howlo nabadgelyo ah, tusaale ahaan la dhaqaaqi karo oo la dhaqaaqi karo ma shaqeyn doono haddii barkinta lagu soo celiyo booska koowaad. Slide ma riixi karto markii la dhaqaaqi karo oo la dhaqaaqi karo. Markay hawlgallo isku dhacu dhacaan, qaylo-dhaan digniin muujineysa shaashadda taabashada oo tus waxa isku dhaca.

Nidaamka kontaroolada korantada

1. Nidaamka korantada wuxuu ka kooban yahay wareegga awoodda iyo wareejinta wareegga. Wareegtada korantada waa 380V, 50hz, oo mas'uul ka ah bilaabida, joojinta iyo ilaalinta matoorka bamka. Nidaamka wareegga ee kontaroolada wuxuu qaadayaa xakameeyaha PLC ee PLC ee lagu daray xakameynta shaashadda taabashada taabashada si loo garto geedi socodka kala duwan ee hawsha ee qalabka mashiinka.

2. Qeybaha kontoroolka korantada ee korantada ee korantada ayaa lagu rakibay golaha xakameynta ee ugu weyn, waxaana golaha kanta kantaroolka ugu weyn lagu dhejiyaa dhulka ku yaal dhinaca midig ee qulqulka; Qalabka fulinta qalabka ayaa ku xidhan fiilooyinka jilicsan, ka-baxa golaha wasiirada ee ugu weyn waa mid joogto ah, oo khadadka kontaroolada ayaa lagu xirayaa furaha duulista ee si fudud loogu kala sooco dib-u-dhigga.

3. Hawlaha ugu weyn ee kantaroolka ee qaybta xakamaynta waxaa loo qaadaa "PLC" Lopeoller Lopeoller. Marka loo eego baahiyaha hawsha, amarradii ay soo saareen qaybaha ugu weyn ee kontaroolada (daminta xulashada, badhamada, iwm.), Iwm.), Iwm. Actuetor-dhululubo, ka dibna buuxi habka wax soo saarka ee mashiinka.

Stroke ee slide-ka ah waxaa gacanta ku haya dareenka barokaca ee buuxda. Shuruuca barokaca ayaa lagu habeeyay qaybta kore ee gudaha safka. Bartilmaameedka iyo barta wareejinta ee booska ayaa si toos ah loo dejin karaa oo lagu soo bandhigi karaa shaashadda taabashada. Intaas waxaa sii dheer, waxaa jira wareejinta xadka sare iyo hoose ee xadka laba-meeloodeed ee xaaladaha lama filaanka ah.

4. Gudiga xakameynta hawlgalka dhexe ee qalabka waxaa loo habeeyay golaha xakameynta ee ugu weyn, iyo shaashadda soo-saaraha ee la taaban karo ee loo yaqaan 'Toottons Tilmaanta' iyo Beddelka Xaaladda Qaranka. Wareegtada korantada waa 380V, 50hz, oo mas'uul ka ah bilaabida, joojinta iyo ilaalinta matoorka bamka. Nidaamka wareegga ee kontaroolada wuxuu qaadayaa xakameeyaha PLC ee PLC ee lagu daray xakameynta shaashadda taabashada taabashada si loo garto geedi socodka kala duwan ee hawsha ee qalabka mashiinka.

Qeybaha kontarooga kontaroolada korantada ugu weyn waxaa lagu rakibay golaha xakameynta ee ugu weyn, waxaana golaha kanta-maareynta ugu weyn lagu dhejiyaa dhulka ku yaal dhinaca midig ee qulqulka; Qalabka fulinta qalabka ayaa ku xidhan fiilooyinka jilicsan, ka-baxa golaha wasiirada ee ugu weyn waa mid joogto ah, oo khadadka kontaroolada ayaa lagu xirayaa furaha duulista ee si fudud loogu kala sooco dib-u-dhigga.

5. Hawsha aasaasiga ah ee kantaroolka qayb ka mid ah ayaa loo maleeyaa inuu yahay "PLC" Lopeoller Lopeoller. Marka loo eego baahiyaha hawsha, amarradii ay soo saareen qaybaha ugu weyn ee kontaroolada (daminta xulashada, badhamada, iwm.), Iwm.), Iwm. Actuetor-dhululubo, ka dibna buuxi habka wax soo saarka ee mashiinka.

Stroke ee slide-ka ah waxaa gacanta ku haya dareenka barokaca ee buuxda. Shuruuca barokaca ayaa lagu habeeyay qaybta kore ee gudaha safka. Bartilmaameedka iyo barta wareejinta ee booska ayaa si toos ah loo dejin karaa oo lagu soo bandhigi karaa shaashadda taabashada. Intaas waxaa sii dheer, waxaa jira wareejinta xadka sare iyo hoose ee xadka laba-meeloodeed ee xaaladaha lama filaanka ah.

6. Gudiga xakameynta hawlgalka dhexe ee qalabka waxaa loo habeeyay golaha xakameynta ee ugu weyn, iyo shaashadda soo-saaraya ee warshadaha taabashada, tilmaanta heerka loo yaqaan 'Tilmaanta' Tilmaamaha Gobolka iyo Beddelka Qaranka iyo Suuqa Xulashada waxaa lagu habeeyay guddiga.

Nidaamka hydralic

Muuqaal:

1. Haanta shidaalka ayaa lagu dejiyay nidaamka filterka qaboojinta ee qaboojinta (aaladda biyo-qaboojinta biyaha noolaha ee noolaha ah, qaboojinta iyadoo la wareejinayo biyaha, heerkulka saliida≤55℃,Hubso in mashiinka si isdaba joog ah loogu cadaadiyo 24 saacadood gudahood.

2. Nidaamka biyo-mareenka wuxuu qaadanayaa nidaamka kontaroolada isku-dhafan ee kartoonada oo leh xawaare deg deg ah oo xawaare sare iyo hufnaan sare leh.

3. Haanta saliida waxay ku qalabaysan tahay shaandhada hawada si ay ula xiriiraan bannaanka si loo hubiyo in saliida biyo-baxa uusan wasakheynin.

4. Xiriirka ka dhexeeya waalka buuxinta iyo haanta shidaalka waxay isticmaashaa kala-goyn dabacsan si looga hortago gariirka in loo gudbiyo haanta shidaalka oo gebi ahaanba xalliso dhibaatada daadashada saliida.

Dhaqdhaqaaq farsamo

1.Mashiinka Saxaafadda waxaa lagu samayn karaa 4 habeed: hagaajin (inji ah), buugga), buugga, semi-otomatiga ah, qaabka shaqada, qaabka shaqada ayaa sidoo kale loo qaybin karaa 2 habeyn ah: sameynta joogtada ah iyo sameynta cadaadiska joogtada ah

2. Qaabka joogtada ah:Marka jagooyinka hadda socda ee slide iyo barkinta ay gaaraan booska hore, shaqada hadda jirta waa la joojiyay. Qiimaha joogtada ah ee bogagga ayaa ku jira inta u dhexeysa inta u dhexeysa stroke buuxa.

3. Qaabka cadaadiska-joogtada ah:Marka cadaadiska hadda jira ee slide iyo barkinta ay gaaraan cadaadiska hore, shaqada hadda la joojiyay ayaa la joojiyay.

4. Dib-u-habeynta (Injirka):Ku shaqeyso badhamada u shaqeysa si ay u dhammaystiraan falalka u dhigma. Riix batoonka hal waqti ayaa ka dhigaya mashiinka saxaafada inuu dhammaystiro hal mar inji. Mashiinka saxaafadda waa la joojiyaa marka badhanka la sii daayo. Qaabkan ayaa inta badan loo isticmaalaa in lagu hagaajiyo mashiinka saxaafadda oo uu ku beddelo dhinta.

5. Buugga:Riix badhanka shaqo kasta si aad u dhammaystirto ficil isleeg, riixitaan kasta oo dhammeystiran 1 ficil waqti.

6. Semi-otomatic:Badhanka Riit-ka-riix si aad u dhammaystirto hal wareeg: Marka badhanka gacan-ku-gudubka la cadaadiyo, mashiinka saxaafadda wuxuu dhameystirayaa go'an ficillo hannaan ah (geedi socodka wareegga waa inuu noqdaa proset)

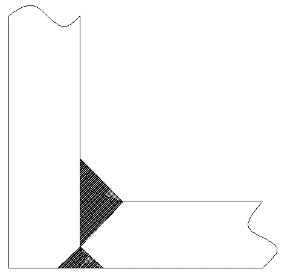

Qoraallada alxanka ee jirka weyn

| Hab | TLCH | KB | Weydiisasho |

|

| A-dhinaca h = t2/3 B-dhinaca h = t1 / 3 C≥4 l≤3 | A-dhinaca 60 ° B-dhinaca 35 ° 1 / 4≤k≤t | Laba-gees oo kacsan-weld marka hore gadaal-weld, cosmetic-kii ugu dambeeyay ee Weld |

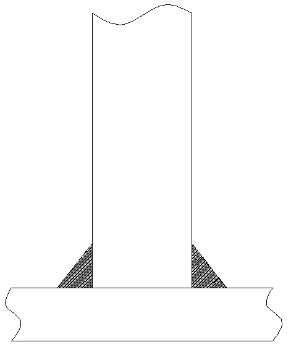

| Burburinta dhululubo

| Marka loo eego sawirka | Marka loo eego sawirka | Laba-geesood-laba-dhinac ah marka hore gadaal ka dib gadaal, ka dib markii la isku qurxiyo-weld uu ilaaliyo kuleylka |

| A-dhinaca h = t / 2 B-dhinaca h = t / 3 C≥4 l≤3 | A-dhinaca 60 ° B-dhinaca 35 ° 1/4-ak≤10 | Laba-gees oo kacsan-weld marka hore gadaal-weld, cosmetic-kii ugu dambeeyay ee Weld |

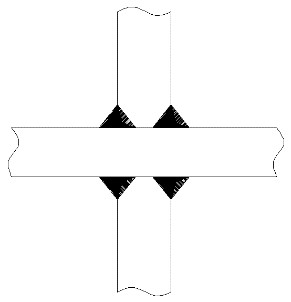

| V-Qabow groove h = t / 3 C≥4 l≤3 | 40oo≤b60o 1/4-ak≤8 | Laba-gees oo kacsan-weld marka hore gadaal-weld, cosmetic-kii ugu dambeeyay ee Weld |

| Laba-v ging H = t / 3 C≥4 l≤3 | 40oo≤b60o 1/4-ak≤8 | Laba-gees oo kacsan-weld marka hore gadaal-weld, cosmetic-kii ugu dambeeyay ee Weld |

| V-Qabow groove h = t / 3 C≥4 l≤3 | 40oo≤b60o 1/4-ak≤8 | F-Furning socodsiinta sida kor ku xusan, weelka saleefin ee alxanka ka dib marka t-qaabku dhammaaday |

|

| V-Qabowt h = t2/3 C≥4 l≤3 | B:60o 1/4-ak≤10 | tack-weld marka hore gadaal-weld, cosmetic-ka ugu dambeeya-weld |

Miiska dulqaadka qaab dhismeedka jirka

| Qaab | Wax | Dulqaad |

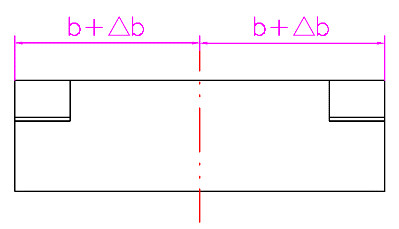

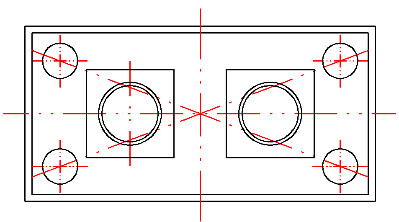

| Summetry walxaha dibedda ee qaab dhismeedka(Joojinta dulqaad△ b) | B≤1000 △ bé.5 1000 b>2000△ bs △3.0 |

| Qaab dhismeedka qaab dhismeedka(dulqaad u dulqaadashada△ l) | L≤2000 △ l≤ l≤3.0 2000 L>4000△ l≤5.0 |

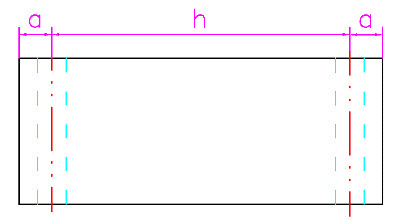

| Isbarbar dhig u dhexeeya dusha sare iyo dhulka qaab dhismeedka t(Ujeedada ay ku jiraan taarikada sare iyo kan hoose) | H≤4000 t t≤2.0 4000 h>8000 t oo ah5.0 |

| Si khaldan u ah guddiyada sare iyo hoose ee qaab dhismeedka | L≤2000 t t≤2.0 L> 2000 to≤3.0 |

Dulqaadashada xagal alxamin ah

| Heer u qaybin | Cabbirka Gaaban ee MM | |||

| ≤315 | >315 ~ 1m | >1 ~ 2m | >2m | |

| A | ≤1.5 | ≤2.0 | ≤2.5 | ≤3.0 |

| B | ≤2.5 | ≤3.0 | ≤3.5 | ≤4.0 |

| A | ± 20 ' | ± 15 ' | ± 10 ' | _ |

| B | ° 1 ° | ± 45 ' | ± 30 ' | _ |

Dulqaadashada qaabka alxanka iyo booska

| Heer u qaybin | Cabirka aasaasiga ah mm | |||||

| ≤315 | >315 ~ 1 | >1 ~ 2m | >2 ~ 4m | >4 ~ 8m | >8m | |

| A | 1.0 | 1.5 | 2.0 | 3.0 | 4.0 | 5.0 |

| B | 2.0 | 3.0 | 4.0 | 6.0 | 8.0 | 10.0 |

| C | 3.0 | 5.0 | 9.0 | 11.0 | 16.0 | 20.0 |

Butt laabatada

Butt laabatada

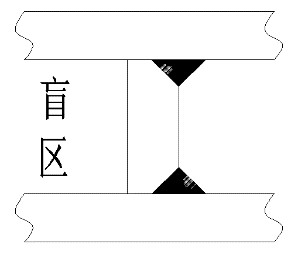

Cir iszcom

Cir iszcom