Otomatiga si otomaatig ah oo magnete ah hydralic saxaafadda

Waxyaabaha ka mid ah mashiinka: riix (oo ay ku jiraan xirmo silig oo la bidka ah), oo ah xirmo bamgareedka biyaha), golaha hayaha kontaroolada korantada, duritaanka, mudista iyo nidaamka isku-darka, haanta faaruqa ah; Qaabka caaryada, si otomaatig ah mashiinka madhan.

WhatsApp: +86 176 0282 8986

Faahfaahinta farsamada aasaasiga ah

1) Nidaamka mashiinka mashiinka mashiinka loo yaqaan 'steral servat servralic' ayaa loo isticmaalaa in lagu qaboojiyo saliida cadaadiska si loo hubiyo cadaadiska, xasilloonida iyo isku halaaliga marka saxaafaddu si joogto ah loo isticmaalo si joogto ah waqti dheer;

2) Isticmaalka tamarta yar iyo keydinta awoodda. Isticmaalka awoodda ee mashiinka oo dhan wuxuu la mid yahay kan saxaafadda 150-tan, iyo wax soo saarka wareejinta ayaa ah 53% in ka badan kan saxaafadda 150-tan ah;

3) Saldhigga caloosha ee caadiga ah ayaa lagu hagaajiyaa kooxda martida loo yahay, oo qaybaha caaryada caaryada si dhakhso leh ayaa loo kala saari karaa oo la badali karaa markii caaryada la beddelo, iyo salka caaryada iyo caaryada ay madax-bannaan yihiin;

4) Jirka ugu weyn waa bir bir oo buuxda (ama bir bir ah), iyo kuwa hoose, iyo kuwa hoose, saldhigyada caaryada, saldhigyada caaryada, silig saqafka leh, iwm dhammaantood waa qaybo bir ah. Xoog farsamo yaqaan ah, qaab dhismeedka is haysta, aag isku dhafan, ku rakiban yar, ku habboon buugga gacanta ama otomatiga ah;

5) Qeybta ugu weyn waa qaab-dhismeedka afarta-sadarka ah, kaasoo korsanaya xirmo silig oo hawo sare leh oo qaboojiya.

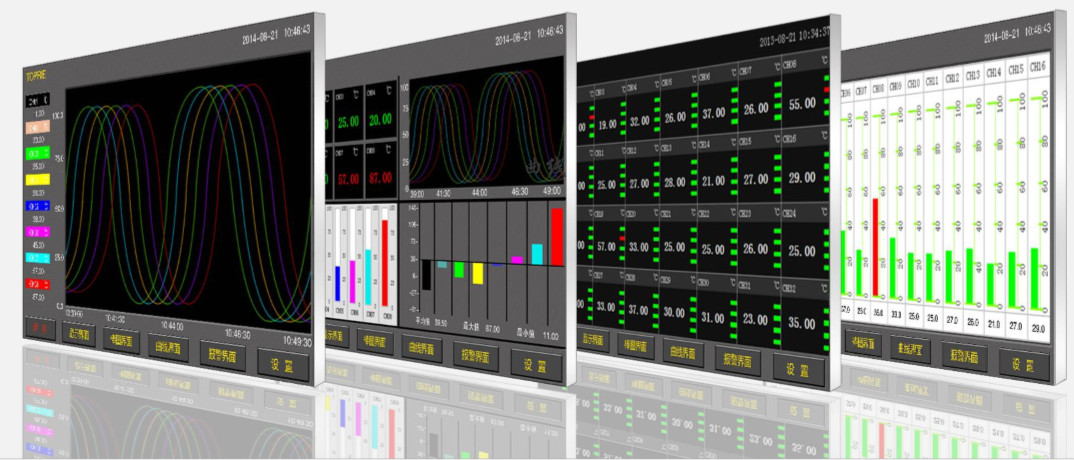

6) Kordhin shaashadda taabashada iyo dareeraha si aad u ogaato interface-ka-Man, dib-u-dejintu waa mid ku habboon oo soon ah;

7) Waxyaabaha ku jira hydraulic ee saldhigga bamka sare ee cadaadiska waxay isticmaalaan tuubooyinka farsamada ee Talyaaniga,

8) Ku qanci ku qancinta waxyaabaha biyaha hooseysa (34% biyo-mareenka) duriin otomaatig ah, xasillooni oo xasilloon oo la isku halleyn karo

Kiis shirkadeed

Cabirrada Mashiinka

| Magac | Cutub | Qiimayn | |

| Nooc | / | YF-230T | |

| Ciidamada Sare | KN | 2300 | |

| Dhex-dhexaadka dhululubada sare | mm | 360 | |

| Stroke Sare | mm | 495 | |

| Xoogga dhululubo ee hoose | KN | 1000 | |

| Dhexroor hoose | mm | 250 | |

| Stroke hoose ee dhululubo | mm | 145 | |

| Xawaare RAM | Xirid | mm / s | >180 |

| Qaab gaabis ah | mm / s | 2-10 | |

| Si tartiib ah u riixaya | mm / s | 0.02-1.5 (la hagaajin karo) | |

| Roob deg deg ah | mm / s | 0.1-2.5 (la hagaajin karo) | |

| Soo celin | mm / s | >90 | |

| Xawaaraha abaalmarinta | Ka saar | mm / s | 20 |

| Soo celin | mm / s | 35 | |

| Max. Meel bilaash ah oo bilaash ah | mm | 1080 | |

| Cabbirka Shaqada (dhererka dhererka dhererka) | mm | 1460 × 860 | |

| Xidhmada siinta-qaboojinta ee la qaboojiyey | / | Mareejintii-qaboojinta hawada-qaboojinta | |

| Max. Mugga duritaanka ee bamka duritaanka | L | 4.1 | |

| Max. Loading ee isku-darka | L | 180 | |

| Awoodda guud ee mashiinka oo dhan | KW | 65 | |

| Saldhig caar ah | / | 550mm farqiga u dhexeeya saldhigyada caaryada, dhererka 300mm | |

| Waqtiga baaskiilka | S | 60 | |

Tiir

Tilmaamaha hage (tiirarka) ayaa laga sameyn doonaaC45 bir kululoo aad yeelato dhumuc adag oo kala go 'ah 0.0mm. Oo samee daaweyn adag oo xanaaq badan.

Jirka weyn

Naqshadeynta mashiinka oo dhami wuxuu qaatay qaabeynta kombiyuutarka kombiyuutarka iyo falanqaynta aaladda gawaadhi. Xoogga iyo adkaanta qalabka waa wanaagsan yihiin, muuqaalkuna waa wanaagsan yahay. Dhammaan qaybo ka mid ah qaybaha mashiinka ah ee jirka ka mid ah ayaa ku habeeya tayo sare oo bir ah oo bir ah Q345b oo bir bir ah, oo lagu qurxiyo kaarboon dioxide si loo hubiyo tayada alxanka.

Dhululubo

| Qaybo | Fcunidda |

| Foosto dhululubo |

|

| Piston Rod |

|

| Shaaar | Qaadashada Jabaan caanka ah ee Jabaan |

| Qalab | Hanuuniyey by perper perper, caabbinta wanaagsan, hubinta hawlgal muddada dheer ah ee dhululubada |

Nidaamka servo

1.Servo Nidaamka Nidaamka

Mabda 'xakamaynta SPO

Qolka sare ee dhululubo ee sare ee lagu rakibay dareenka cadaadiska, slide ku qalabeysan oo lagu qalabeeyay kontoroolka dareemayaasha barakaca. Sida ku xusan calaamadaha jawaab celinta cadaadiska, seenyaalaha Jawaab-celinta booska, cadaadiska la siiyay calaamadaha, booska la siiyay calaamadaha iyo xawaaraha la siiyay si loo xisaabiyo xawaaraha wareejinta ee servo, si loo xakameeyo wax soo saarka bamka ee cadaadiska, xawaaraha iyo xakameynta booska.

Saxaafadda ayaa ku ansaxisay PID si ay u hagaajiyaan cadaadiska iyo booska, iyada oo loo marayo xawaaraha matoorka ee ka hor xakamaynta xakamaynta loop-ka. Adigoo hagaajinaya xawaaraha 'servo motor', waxay xakameyn kartaa cadaadiska, xawaaraha, booska iyo cabirka kale ee hydralic saxaafadda, iyadoo la baabi'inayo weelka xakamaynta cadaadiska, xargaha xakameynta xakameynta cadaadiska iyo koontaroolka kale ee ku jira xargaha xakameynta hydralic-ka si loo fududeeyo.

3. Fomactors of Nidaamka SPONE

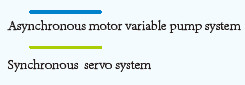

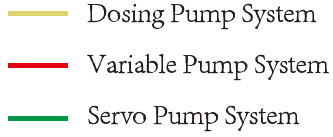

Keydinta tamarta

Marka la barbar dhigo nidaamka matoorka ee caadiga ah ee matoorka, nidaamka matoorka xawaaraha ee xawaaraha xawaaraha ee 'Strepless Pastress' ee Stepless Pasts MotoT MotoT, oo isku-haynta astaamaha cadaadiska saliida ee saliida, kaas oo keena suurtagalnimada tamarta badan ee kaydinta tamarta, iyo tamartaHeerka keydinta ayaa gaari kara ilaa 30% -80%.

Waxqabad leh

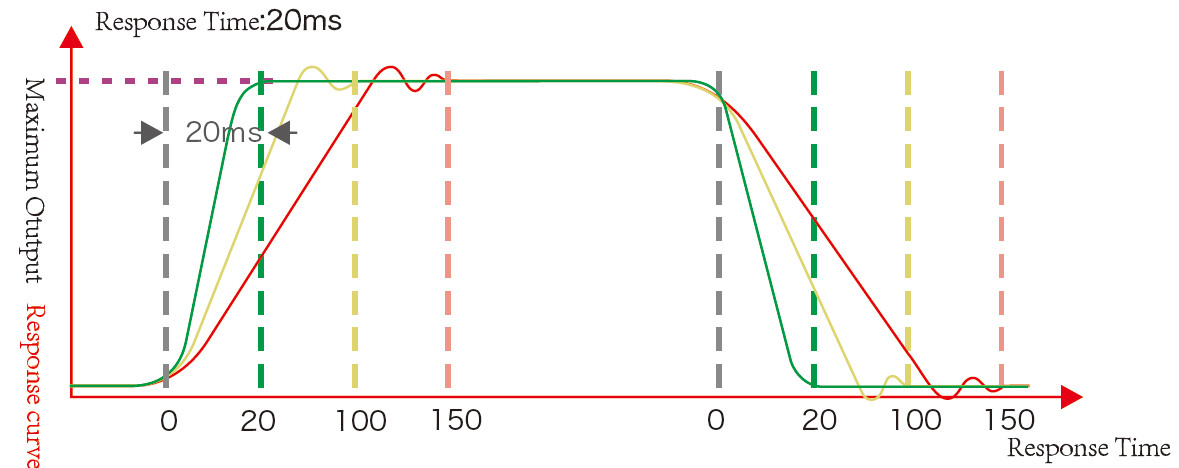

Xawaaraha jawaabta waa mid dhakhso badan oo jawaabtu waxay u gaaban tahay 20ms, oo hagaajinaysa xawaaraha jawaabta ee nidaamka hydralic.

Sax

Xawaaraha jawaab celinta ee degdega ayaa dammaanad qaadaya furitaanka iyo xiritaanka sax ahaanta, saxsanaanta booska ayaa gaari kara 0.1mm, iyo saxsanaanta booska gaarka ah ee shaqada ayaa gaari kara ± 0.01mm.

Qaybta saxda ah ee PID-da-ka-sare ee PID-ka PID waxay xaqiijineysaa cadaadiska nidaamka deggan oo deggan oo isbeddelada cadaadiska ah ee wax ka yar ± 0.5 bar, hagaajinta tayada wax soo saarka.

Ilaalinta deegaanka

Sanqafka: Celcelis ahaan buuqa nidaamka hydraulic servo waa 15-20 dB ka hooseysa kan taranka asalka ah ee la beddelay.

Heerkulka: Kadib nidaamka SPO-da ayaa la istcimaalaa, heerkulka saliida ee hydraulic waa mid hoos udhaca guud ahaan, taas oo xoojineysa nolosha shaabadaasi ama waxay yareysaa awoodda qaboojiyaha.

Barnaamij

Kombuyuutar warshadeed oo badan oo ah warshadeed oo badan oo ah warshadda martigeliyaha ayaa gartay cabbirrada ugu weyn ee geedi socodka iyo dardaaranka qalad ee saxaafadda, oo inta badan ay ku jiraan macluumaadka aasaasiga ah ee soo socda:

● Jir(MPA, ℃) ● Sirta sirta ah ee la ilaaliyo ● Muujinta dijitaalka ah ● XUQUUQDA XUQUUQDA

| Booska Platen, 0 oo si buuxda u fura jadwalka booska oo furan Hawada | Wareegga daaweynta, masraxa barnaamijka.Clack cadaadiska Xawaare

|

Qalabka badbaadada

Ilaalada korantada ee korantada ee korantada hore iyo gadaal

Slide qufulka TDC

Laba qalliin oo istaaga ah

Shuruucda caymiska taageerada ee hydralic

Badbaadinta xad-dhaafka ah: valve block

Alaarmiga heerka dareeraha ah: heerka saliida

Digniinta heerkulka saliida

Qayb kasta oo korantada ayaa leh difaac xad dhaaf ah

Beeraha badbaadada

Nuqulada qufulka waxaa loo bixiyaa qaybo la dhaqaajin karo

Dhammaan ficilka saxaafadda waxay leeyihiin howlo nabadgelyo ah, tusaale ahaan la dhaqaaqi karo oo la dhaqaaqi karo ma shaqeyn doono haddii barkinta lagu soo celiyo booska koowaad. Slide ma riixi karto markii la dhaqaaqi karo oo la dhaqaaqi karo. Markay hawlgallo isku dhacu dhacaan, qaylo-dhaan digniin muujineysa shaashadda taabashada oo tus waxa isku dhaca.

Nidaamka hydralic

Muujinta

Tan waxaa lagu dejiyay haanta loo yaqaan 'qaboojiyaha loo dejiyey nidaamka filterka qaboojinta ee qaboojinta

2. Nidaamka hydralic-ka wuxuu qaadanayaa nidaamka xakamaynta isku-dhafan ee kartoonada oo leh xawaare xawaare dhakhso leh iyo hufnaan sare.

3. Haanta saliida waxay ku qalabaysan tahay shaandhada hawada si ay ula xiriiraan bannaanka si loo hubiyo in saliida biyo-baxa uusan wasakheynin.

4. Xiriirka u dhexeeya wanaagga buuxinta iyo haanta shidaalka waxay isticmaashaa kala-goyn dabacsan si looga hortago gariirku inuu u gudbiyo haanta shidaalka oo gebi ahaanba xalliso dhibaatada daadashada saliida.

5.Maxaad ka samaysan tahay tuubbada saliida ee hydralic Xiriirinta tuubada ayaa ku xiran SaeE Flage sida ugu badan ee suuragalka ah. Waa nooc alxanka ah oo leh saameynta alxanka wanaagsan iyo si wax ku ool ah u xallinaysa dhibaatada daadashada saliidda ee ay sababaan alxanka liita.