Quare his tur holo tum

Boiphihlelo bo nang le Morero oa Boikoetliso le Motho ea Khahlano le Mokhatlo oa Kakaretso oa Puisano ea Bongata le Kutloisiso e Ntle ea Litemoso tsa Tlhaho Re tla u tsebisa ka tsoelo-pele ea rona mme re lebelletse ho haha likamano tse tsitsitseng tsa khoebo le uena.

Morero oa barui o boetse oa ba ruisang le motho ho latela mohlala o le mong oa thuso ho etsa bohlokoa bo phahameng haholo ho puisano ea k'hamphani le kutloisiso ea rona ea ho ba bonolo mabapi le litebello tsa hau tsaChina hydraulic khatiso, H Frame Hydraulic Press, Re boetse re na le likamano tse ngata tsa tšebelisano le bahlahisi ba bangata e le hore re ka fana ka karolo eohle ea likoloi le litšebeletso tse tlase tsa thekiso ea bareki le sebakeng se fapaneng.

Nyeoe ea k'hamphani

Kopo

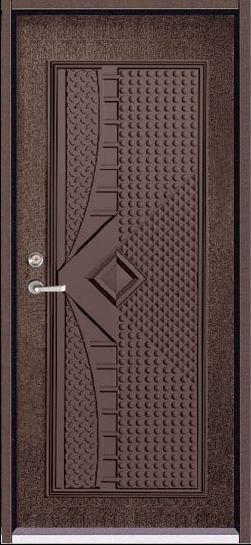

Mochine ona o loketse haholo bakeng sa monyako o mongata oa monyako oa matlung. Lisebelisoa li na le thata bo thata tsa sistimi e thata le ho nepahala haholo, bophelo bo phahameng le bo phahameng bo phahameng. Ts'ebetso ea ho tsoaloa bakeng sa likarolo tsa tšepe tsa tšepe e kopana le li-shifts tse 3 / tsa letsatsi la mantsiboea ..

Li-paramethara tsa mochini

| Lebitso | Yuniti | Boleng | Boleng | Boleng | Boleng | |

| Mohlala | Yz91-4000 | Yz91- 3600t | Yz91-2500t | Yz91-1500t | ||

| Matla a mantlha a silindar | KN | 40000 | 36000 | 25000 | 15000 | |

| Motšehare | mm | 500 | 500 | 500 | 500 | |

| Moriri oa Main Sroke | mm | 400 | 400 | 400 | 400 | |

| Cylinder Qty. | / | 6 | 6 | 6 | 6 | |

| Boholo ba tafole

| LR | mm | 1600 | 1600 | 1400 | 1400 |

| FB | mm | 2600 | 2600 | 2400 | 2400 | |

| Lebelo la Slider | Tlase | mm / s | 80-120 | 80-120 | 80-120 | 80-120 |

| Khutla | mm / s | 100 | 100 | 100 | 100 | |

| Ho sebetsa | mm / s | 10-15 | 10-15 | 10-15 | 10-15 | |

Mold Molf le lipaterone

|  |

Re ka fana ka mekhoa e fapaneng bakeng sa bareki ho khetha, re ka fana ka hlobo. Hlobo e tla lekoa fekthering ea rona.

|  |

Moqhetsoana o na le lintlha tse 1 tsa hlobo le boholo ba boima ba mold, moreki a ka etsa sebopeho se fapaneng, 'me o hloka feela ho reka karolo e le' ngoe ea hlobo.

Sesebelisoa sa polokeho

Setšoantšo sa Ts'ireletso ea Motlakase: Ka pele

Slice Slicking ho TDC

Ho na le ts'ebetso e peli e sebetsang

Hydraulic tšehetsa potoloho ea inshorense

Tšireletso ea ho jara:

Alamo ea metsi: boemo ba oli

Tlhokomelo ea mocheso oa oli

Karolo ka 'ngoe ea motlakase e na le ts'ireletso e fetang tekano

Mekhaea ea polokeho

Linate tsa senotlolo li fanoa bakeng sa likarolo tse matla

Ketso eohle ea mochine o hatellang Slide e ke ke ea tobetsa ha a sa sebetse. Ha ts'ebetso ea ho loanna e etsahala, ho bontša alamo ho tsoa skrineng sa ho ama le ho bonts'a khohlano.

Sistimi ea taolo ea motlakase

1. Tsamaiso ea motlakase e na le potoloho ea potoloho ea potoloho le laola potoloho ea potoloho. Potoloho ea matla ke 380v, 50hz, 50hz, 50hz, e leng boikarabello ba ho qala, ho emisa le ho sireletsa le ho sireletsa koloi ea pompo ea oli. Tsamaiso ea Tsamaiso ea Marang-rang ea PLC e ratoang ea PLC e kopaneng le taolo ea Screen e amehang ho lemoha meqomong e fapaneng ea sesebelisoa sa mochini.

2. Likarolo tse ka sehloohong tsa ho ajoa libetsa tsa matla a taolo ea matla a taolo ea taolo ea taolo, 'me khabinete e ka sehloohong ea taolo e behiloe fatše ka lehlakoreng le letona la fuselage; Likarolo tsa litso tsa ts'ebetso li hokahane le lithapo tse bonolo, Mabone a mantlha a marang-rang a hokahane le plug-Is bakeng sa ho hapa bonolo ka ho fetelletsa thepa.

3. Ts'ebetso ea mantlha ea karolo ea taolo e nahanoa ke "CLC" Coffer e rarolloang ". Ho latela litlhoko tsa ts'ebetso, litaelo tse fanoeng ke likarolo tsa mantlha tsa taolo ea mochini, li-switch tsa "hydraulic" Actiator-silindar, ebe o phethela mokhoa oa tlhahiso oa mochini.

Slider ea slider e laoloa ke sensor e phethahetseng ea ho tsoaloa. Senotlolo sa ho fallela se hlophisitsoe karolong e kaholimo ea bokaholimo ba kahare. Sebaka sa stroke le boemo ba phetoho bo ka beha ka kotloloho le ho bontšoa skrineng ea ho ama. Ntle le moo, ho na le meeli e holimo le e tlase ea ho boloka ts'ireletso e habeli maemong a sa lebelloang.

4. Sehlopha sa taolo e bohareng ba lisebelisoa se hlophisitsoe ka khabinete e ka sehloohong ea li-indasteri tsa marang-rang, li-scretriche tsa ho sebetsa li entsoe ka potoloho ea potoloho le ea taolo. Potoloho ea matla ke 380v, 50hz, 50hz, 50hz, e leng boikarabello ba ho qala, ho emisa le ho sireletsa le ho sireletsa koloi ea pompo ea oli. Tsamaiso ea Tsamaiso ea Marang-rang ea PLC e ratoang ea PLC e kopaneng le taolo ea Screen e amehang ho lemoha meqomong e fapaneng ea sesebelisoa sa mochini.

Kamore ea mantlha ea matla a taolo ea matla a taolo ea lihlahisoa tsa taolo ea taolo ea taolo, 'me khabinete e ka sehloohong ea taolo e behiloe fatše ka lehlakoreng le letona la fuselage; Likarolo tsa litso tsa ts'ebetso li hokahane le lithapo tse bonolo, Mabone a mantlha a marang-rang a hokahane le plug-Is bakeng sa ho hapa bonolo ka ho fetelletsa thepa.

5. Ts'ebetso ea mantlha ea karolo ea taolo e nahanoa ke "CLC" e ratoang ea mantlha " Ho latela litlhoko tsa ts'ebetso, litaelo tse fanoeng ke likarolo tsa mantlha tsa taolo ea mochini, li-switch tsa "hydraulic" Actiator-silindar, ebe o phethela mokhoa oa tlhahiso oa mochini.

Slider ea slider e laoloa ke sensor e phethahetseng ea ho tsoaloa. Senotlolo sa ho fallela se hlophisitsoe karolong e kaholimo ea bokaholimo ba kahare. Sebaka sa stroke le boemo ba phetoho bo ka beha ka kotloloho le ho bontšoa skrineng ea ho ama. Ntle le moo, ho na le meeli e holimo le e tlase ea ho boloka ts'ireletso e habeli maemong a sa lebelloang.

6. Karolo ea taolo ea taolo e bohareng ea lisebelisoa e hlophisitsoe ka khabinete e ka sehloohong ea li-indasteri ea ho bonts'a indasteri ea "

Sistimi ea Hydraulic

Karolo:

1. Tank ea oli e behiloe sesebelisoa sa ho futhumala se futhumatsang sa metsi (sesebelisoa sa mochini sa indasteri, ho pholile ka ho potoloha metsi, mocheso oa oli o khona ho hatelletse lihora tse 24.

2. Systeric System e atolositsoeng e kopantsoeng ea Carver ea Cardge ea Carver ea Carver ea ho laola ka lebelo le lebelo la karabelo e potlakileng le mokhoa o phahameng oa ho fetisetsa.

3. Tloaetso ea oli e na le sefako sa moea ho buisana le ka ntle ho netefatsa hore oli e hydraulic e sa silafetse.

4. Khokahano lipakeng tsa valve e tlatsitsoeng 'me tanka ea mafura e sebelisa mohono o bonolo oa ho thibela ho silafatsoa hore se fetisoe ka tankeng ea mafura ebe u rarolla bothata ka botlalo.

Mohato oa mahlale

1.Mochine oa khatiso o ka sebetsoa ka mekhoa e 4: Phetoho (ho kenella ka boiketsetso

2. Mokhoa oa holeHa maemo a hajoale a thetso le mosamo a fihla boemo ba preet, mosebetsi oa hona joale oa emisoa. Boleng ba hole ba li-slide li ka har'a mefuta e mengata ea slide e felletseng.

3. Mokhoa oa khatello:Ha likhatello tsa hona joale tsa thetso le mosamo li fihla khatello ea sepache, mosebetsi oa hona joale oa emisoa.

4. Phetoho (ho honotha):Sebetsa li-button tse tsamaellanang tsa sebetsang ho tlatsa liketso tse tsamaellanang. Ho tobetsa konopo ka nako e le 'ngoe ho etsa hore mochini oa khatiso o phethe nako e le' ngoe. Mochini oa khatiso o emisitsoe ha konopo e lokolloa. Mokhoa ona o sebelisoa haholo ho lokisa mochini oa khatiso ebe o khutlisa ho shoa.

5. Bukana:Sututsa konopo e 'ngoe le e' ngoe ea ts'ebetso ho phethela ketso e tšoanang, sutu e 'ngoe le e' ngoe e felletse ka nako ea 1 ka nako.

6. Semi-Isomatic:Konopo ea Handy-Double ho tlatsa potoloho e le 'ngoe: Ha konopo e bonolo e hatelloa, mochini oa khatiso o phethetse karolo ea liketso tsa tšebetso (ts'ebetso ea potoloho e lokela ho ba pona)

Tekanyo ea weld ea 'mele oa mantlha

| Setaele | Tlch | KB | Tlhokahalo |

|

| N = t2 / 3 B-Side H = t1 / 3 C 94 L≤3 | Ka lehlakoreng la 60 ° B-ka lehlakoreng la 35 ° 1 / 4≤kktt | Ka lehlakoreng le leng la tack-weld e ka morao-rao ea morao-rao ea morao-rao-weld, cosmetic ea ho qetela-weld |

| Moqomo o ka tlase

| Ho latela ho taka | Ho latela ho taka | Ka lehlakoreng le leng la tack-weld e ka morao-rao ea morao-rao ea morao-rao ea morao-rao |

| N = t / t / 2 B-Side H = T / 3 C 94 L≤3 | Ka lehlakoreng la 60 ° B-ka lehlakoreng la 35 ° 1 / 4≤k emal10 | Ka lehlakoreng le leng la tack-weld e ka morao-rao ea morao-rao ea morao-rao-weld, cosmetic ea ho qetela-weld |

| V-Shape Groove H = T / 3 C 94 L≤3 | 40o≤60 1 / 4≤k≤8 | Ka lehlakoreng le leng la tack-weld e ka morao-rao ea morao-rao ea morao-rao-weld, cosmetic ea ho qetela-weld |

| Double-v Groove H = t / 3 C 94 L≤3 | 40o≤60 1 / 4≤k≤8 | Ka lehlakoreng le leng la tack-weld e ka morao-rao ea morao-rao ea morao-rao-weld, cosmetic ea ho qetela-weld |

| V-Shape Groove H = T / 3 C 94 L≤3 | 40o≤60 1 / 4≤k≤8 | Ts'ebetso ea sebopeho joalo ka holimo, ho thella poleiti ea poleiti ka mor'a ho qala |

|

| V-sharo groove h = t2 / 3 C 94 L≤3 | B≤60 1 / 4≤k emal10 | Tack-weld pele-weld, cosmetic ea ho qetela-weld |

Tafole ea matichere a sebopeho sa mmele

| Sebopeho | Ntho | Ho mamella |

| Symmetry ea likarolo tsa kantle tsa sebopeho sa fuselage (ho mamella ho mamella | B≤1000 △ b≤1.5 1000 B> 2000 △ b≤3.0 |

| Fusela sebopeho sa furu | L≤2000 △ l≤3.0 2000 L> 4000 △ l≤5.0 |

| Ho tšoana ho pakeng tsa sebaka se kaholimo le sebaka sa kholomo ho kenyelletsa lipoleiti tse holimo le tse tlase) | h≤4000 t≤2.0 4000 H> 8000 t≤5.0 |

| Missallignment ea Boards ea holimo le e tlase ea sebopeho sa Fussilage | L≤2000 t≤2.0 L> 2000 t≤3.0 |

Ho mamella ka nako ea welding

| Keletso | Boholo bo bokhutšoanyane mm | |||

| ≤315 | > 315 ~ 1m | > 1 ~ 2m | > 2m | |

| A | ≤1.5 | ≤2.0 | ≤2.5 | ≤3.0 |

| B | ≤2.5 | ≤3.0 | ≤3.5 | ≤4.0 |

| A | ± 20 ' | 15 ' | 10 ' | _ |

| B | ± 1 ° | 50 4 ' | ± 30 ' | _ |

Ho mamella ha sebopeho le boemo

| Keletso | Boholo ba Mm | |||||

| ≤315 | > 315 ~ 1 | > 1 ~ 2m | > 2 ~ 4m | > 4 ~ 8m | > 8m | |

| A | 1.0 | 1.5 | 2.0 | 3.0 | 4.0 | 5.0 |

| B | 2.0 | 3.0 | 4.0 | 6.0 | 8.0 | 10.0 |

| C | 3.0 | 5.0 | 9.0 | 11.0 | 16.0 | 20.0 |

Boiphihlelo bo nang le Morero oa Boikoetliso le Motho ea Khahlano le Mokhatlo oa Kakaretso oa Puisano ea Bongata le Kutloisiso e Ntle ea Litemoso tsa Tlhaho Re tla u tsebisa ka tsoelo-pele ea rona mme re lebelletse ho haha likamano tse tsitsitseng tsa khoebo le uena.

Boleng bo phahamengChina hydraulic khatiso, H Frame Hydraulic Press, Re boetse re na le likamano tse ngata tsa tšebelisano le bahlahisi ba bangata e le hore re ka fana ka karolo eohle ea likoloi le litšebeletso tse tlase tsa thekiso ea bareki le sebakeng se fapaneng.

Butt Joint

Butt Joint

Powzone

Powzone