Metal Pooder ea Hydraulic Pustic Pustralic Pustic

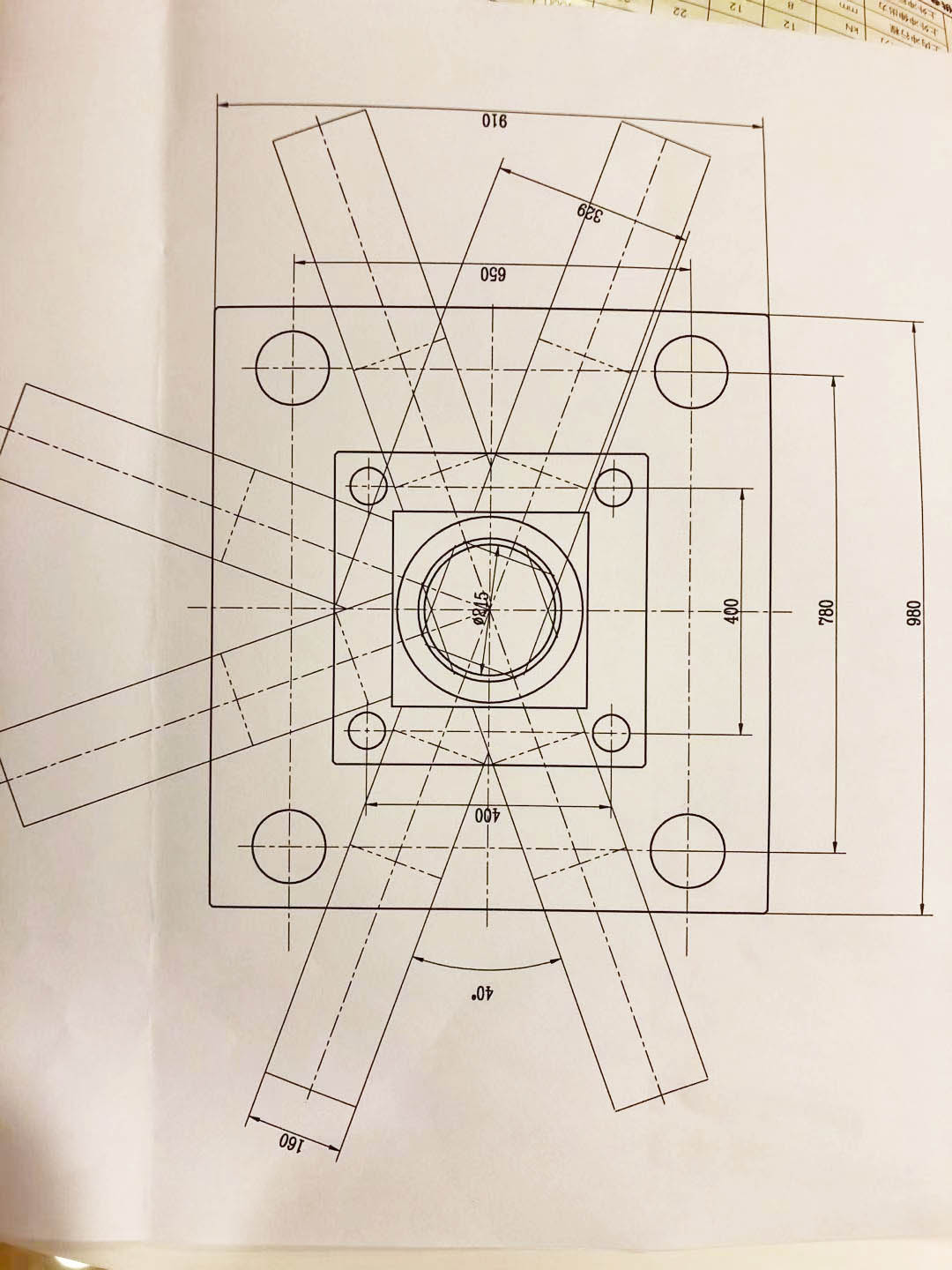

Mold Frame

1) Setheo sa Mold se etsoa haholo ho 40cr le 4 # steel ka ho theha, ho tsitsipana le ho slinding ho netefatsa hore e lekane le ho nepahala. Sebaka se tataisang se emelang mathata a ho sireletsa holimo ho tloha ahahaha, joalo ka mokotla oa thotaki oa koporo. Ka khalase.

2) Karolo e kaholimo ea mold Frame ke punch e le 'ngoe e kaholimo,' me punch e kaholimo e tiiselitsoe ka kotloloho ho Puching ea Putin e holimo; Mohloli oa mosali o ts'oarehile ka lerethemeng le mpe, 'me bobeli ba khatello ea ho phaphamalang le khatello ea ho phaphamalang li etsoa ts'ebetsong ea khatello ea maikutlo. Ka thata ba khetha ka thata, "phofo", khatello ea maikutlo, khatello ea khatello ea khatello ea khatello ea khatello ea maikutlo, jj. E ka phethahala ha o tobetsa. Ha li ntse li tsamaea phofo, hlobo e holimo le e tlase e phaphametseng e felisitsoe ka sekhahla se kaholimo.

3) Mokhoa o shoeleng o na le matla a fetohileng le tšireletso a semetsoeng ho khetho; Mo hloeana le litho tsa botšehali li na le lefu le ts'oanang le hlobolo le 'mala oa litho tsa tlhaho ho molemo ho sireletsa sehlahisoa hore se senyehe habonolo.

4) Ho fepa bophahamo ba sehlahisoa, bophahamo ba sehlahisoa le boemo ba ho shoe li sebelisa ho nepahala ha lihlahisoa tsa ho bona boemo le moeli oa sesebelisoa.

5) Lingoliloeng tse seng tsa tšepe li kentsoe hammoho pakeng tsa poleiti e phaphametseng le sekoti sa polokelo ea tšepe, 'me likarolo tsohle tsa tšepe li sa kopane le phofo ea thepa e tala.

Sisteme ea ho fepa

1.The ho iphetlo ho tla ba le batho ba 6 bapper, 'me hopper e' ngoe le e 'ngoe e tla beha thepa e fapaneng e tala.

2.The Hopper e ka potoloha, 'me e na le matla a matle.

3.AITOLINAMAMA SUPRING EA LITLHAKISO TSE KHOLO, 5-10 metswana.

Bongata ba "hopper bo sa sebetse bo ka beoa ho HMI, 1,2,3 ... 10, ea sebetsang hammoho.

5.6 Ho kentsoe batho ba baholo ba tla kenngoa ka holim'a mochini, hopper e 'ngoe le e' ngoe e ka boloka lik'hilose tse 15 ea phofo.

Pilara

Lipolum tse tataisang (litšiea li tla etsoaC45 e chesang e hlohlora tšepe'me u be le botenya tse thata tsa choating e ka bang 0.08mm. 'Me u etse kalafo e thata le e futhumatsang.

Melao ea Tlhahiso ea Lihlahisoa

JB / T3818-99-99"Maemo a botekgeniki a khatiso ea hydraulic"

GB5266.1-2002"Tširekeho ea mechin ea metjello"

GB / t 3766-2001"Litlhoko tsa kakaretso tsa tekheniki bakeng sa lits'ebetso tsa Hydraulic"

GB17120-97"Tobetsa Litlhapi tsa TORCTANE TEKELENG EA TEMOSION"

JB9967-99"Mochini oa hydraulic o lerata moeli"

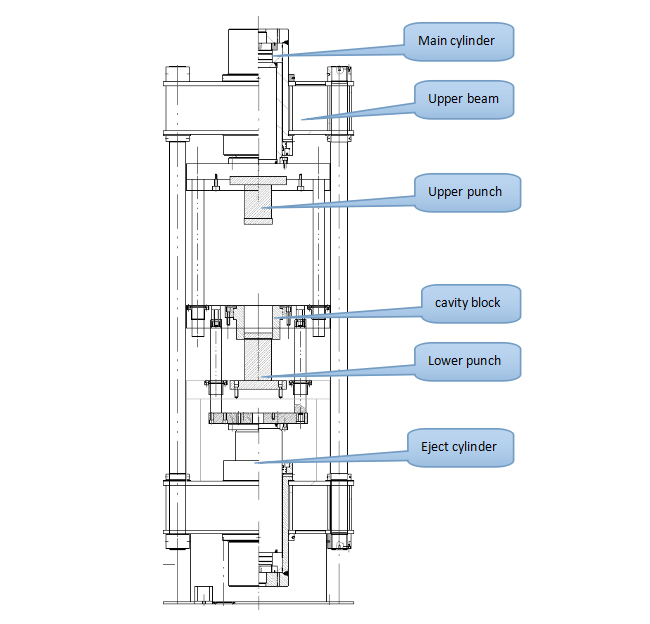

Mmele o ka sehloohong

Moralo oa mochini kaofela o amohela moralo oa ts'ebetso oa k'homphieutha ea k'homphieutha ea k'homphieutha le sekaseka ka ntho e lekantsoeng. Matla le ho tsitsa ha lisebelisoa li ntle, 'me ponahalo e lokile. Likarolo tsohle tsa mochini oa mochini li entsoe ka poleiti ea boleng bo phahameng ea Stered e phahameng ea tšepe

Silindar

| Dikarolo | FHo ja |

| Moriri oa Moriri |

|

| Piston Rod |

|

| Lials | Amopisa Jak Nok Branditing |

| Piston | Taisoa ke ho kenella ka koporo, ho khathala ho hotle ho hanyetsa, ho netefatsa ts'ebetso ea nako e telele ea silinda |

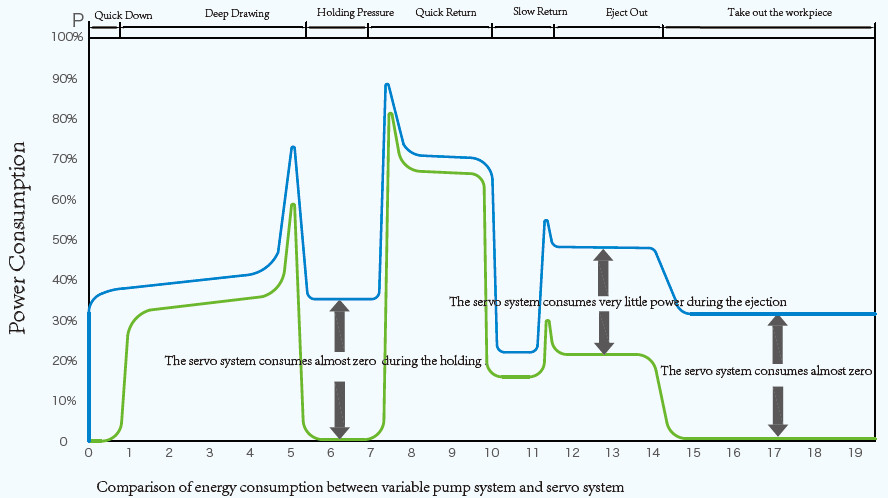

Sistimi ea Servo

1. sebopeho sa sistimi ea sistimi

Mehato ea tsamaiso ea Servo System

Ho boloka Matla

Ho bapisoa le Sistimi ea Sebopeho sa Great e fapaneng, sistimi ea oli ea ServoHo boloka sekhahla se ka fihla ho 30% -80%.

E sebetsa hantle

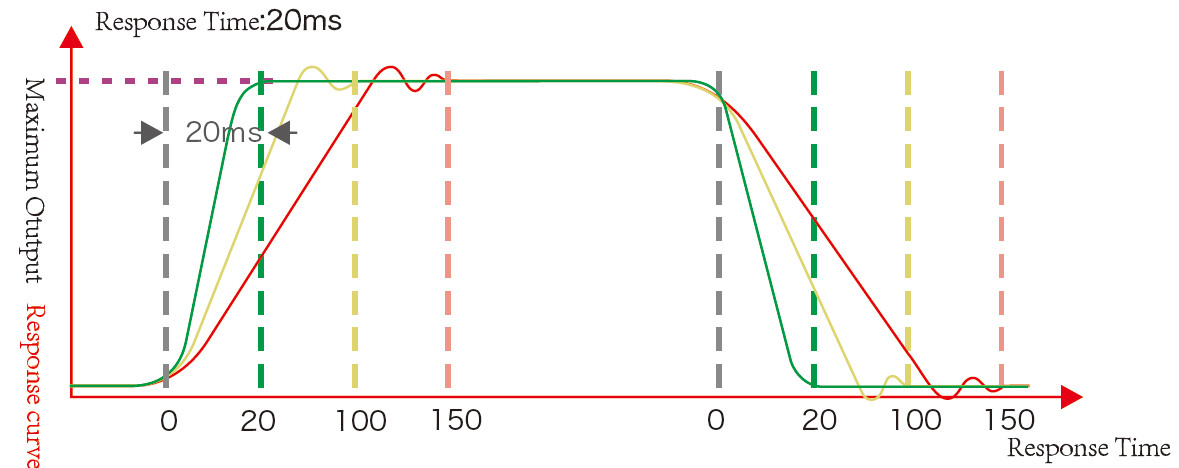

Lebelo la karabelo le potlakile 'me nako ea karabelo e khuts'oane joalo ka 20ms, e ntlafatsang lebelo la tsamaiso ea hydraulic.

Ho nepahala

Lebelo la ho potlaka la karabelo le tiisa ho nepahala le ho koala ka nepo, boemo bo ka fihlela 0.1mm, le boemo bo ikhethang ba ts'ebetso bo ka fihla± 0,01mm.

Modumo o phahameng, o ile a netefatsa khatello ea maikutlo le khatello ea khatello ea maemo a tlase ho± 0,5 Bar, ho ntlafatsa tšobotsi ea sehlahisoa.

Ts'ireletso ea tikoloho

Lerata: Molumo o tloaelehileng oa sistimi ea hydraulic Serdara e 15-20 db e tlase ho feta ea pompo ea mantlha e fapaneng.

Mocheso: Kamora hore tsamaiso ea mehele e sebelisetsoa ka botlalo, e ntlafatsang bophelo ba tiiso ea hydraulic kapa e fokotsa matla a pholileng.

Sesebelisoa sa polokeho

Setšoantšo sa Ts'ireletso ea Motlakase: Ka pele

Slice Slicking ho TDC

Ho na le ts'ebetso e peli e sebetsang

Hydraulic tšehetsa potoloho ea inshorense

Tšireletso ea ho jara:

Alamo ea metsi: boemo ba oli

Tlhokomelo ea mocheso oa oli

Karolo ka 'ngoe ea motlakase e na le ts'ireletso e fetang tekano

Mekhaea ea polokeho

Linate tsa senotlolo li fanoa bakeng sa likarolo tse matla

Ketso eohle ea mochine o hatellang Slide e ke ke ea tobetsa ha a sa sebetse. Ha ts'ebetso ea ho loanna e etsahala, ho bontša alamo ho tsoa skrineng sa ho ama le ho bonts'a khohlano.

Sistimi ea Hydraulic

1.OIL tanka e hlophiselitsoe ho futhumatsa sesebelisoa se futhumetseng sa metsi

Ts'ireletso ea HYDRAULIC e alima ts'ebetso e kopaneng ea Carver ea Cartridge Vaves le lebelo le potlakileng le lebelo le phahameng la phetisetso.

3.Ke tanka ea oli e na le sefako sa moea ho buisana le sona ka ntle ho netefatsa hore oli ea hydraulic e sa sitisoa.

4.A khokahano lipakeng tsa valve e tlatsitsoeng 'me tanka ea mafura e sebelisa chelete e ngata ho thibela ho silafatsoa hore e fetisoe ka tankeng ea mafura ebe u rarolla bothata ka botlalo.