Ho bata ha ho bata le ho chesa ke lits'ebetso tse peli tsa bohlokoa lebaleng la tšepe ea tšepe. Li na le liphapang tse kholo ka har'a polasetiki ea thepa, maemo a mocheso, likokoana-hloko le tsa kopo. Sehloohong sena, re tla tšohla ka botlalo litšobotsi tsa mekhoa ena e 'meli, hammoho le mochini oa ho bata le ho chesa haholo tlhahiso ea' nete.

Phapang pakeng tsa ho bata le ho chesa

Ho foka sefuba ho bua ka mokhoa o phethoang o entsoe ka mocheso oa kamore, 'me mocheso oa tšepe o le tlase ho mocheso oa ho boelana. Ka lebaka la sepolesa se futsanehileng sa thepa ka mocheso o tlase, hangata ho tsitsipana hangata ho hloka matla a maholo ho phethahatsa matla a polasetiki. Ka hona, ho bata ho bata ho loketse lisebelisoa tsa alloy tse nang le matla a phahameng. Ho chesa ho chesa ke mokhoa o kenang o entsoeng tlas'a maemo a mocheso o phahameng, 'me mocheso oa mochini oa tšepe o phahame ho feta mocheso oa ho boelanela. Ka lithemparelong tse phahameng, tšepe e na le polasetiki e ntle, ho chesa haholo ho hloka ho sebelisa matla a fokolang, a loketseng mefuta e fapaneng ea lisebelisoa tsa tšepe.

Phapang ea mocheso pakeng tsa ho holofala e bata le ho chesa e na le tšusumetso e kholo ea likokoana-hloko tsa thepa eo. Nakong ea ho bata, lithollo tsa tšepe ha li se tloaelo ea ho pheta-pheta, kahoo morphology ea litho tsa pele hangata e bolokiloe kamora ho bata. Ka lebaka la matla a matla a matla, lijo-thollo tsa tšepe li bonolo ho nchafatsa mocheso o moholo, kahoo sebopeho se tšoanang le se tšoanang le se nang le lijo-thollo se fumanoa ka mor'a ho chesa. Ka hona, ho chesa ho chesa ho ka ntlafatsa ho utloaha ka thata le lebotho la thepa ea thepa.

Ntle le moo, ho bata ha ho bata ebile ho chesa ho chesa ho na le likarolo tse fapaneng ka kopo e sebetsang. Ho bata ha bata haholo ho etsoa haholo ho etsa li-aloy tsa aloy tsa matla a maholo le polasetiki e tlase, joalo ka tšepe e matla joalo. Hobane ho foka ho bata ho hloka ts'ebeliso ea matla a maholo, ka kakaretso o sebelisoa ho etsa mesebetsi e menyenyane e bopehileng le e bonolo. Ho chesa ho chesa ho loketse lisebelisoa tse ngata tsa tšepe. E ka etsa mesebetsi ea machabeng ea nang le libopeho tse rarahaneng mme e ka ntlafatsa ho utloane le sekhukhuni ba thepa. E sebelisoa haholo ho etsa thepa e kholo ea indasteri e joalo ka likarolo tsa likoloi, likarolo tsa aerospace, le mochini oa boenjiniere.

Mochini o batang o batang le mochini o chesang

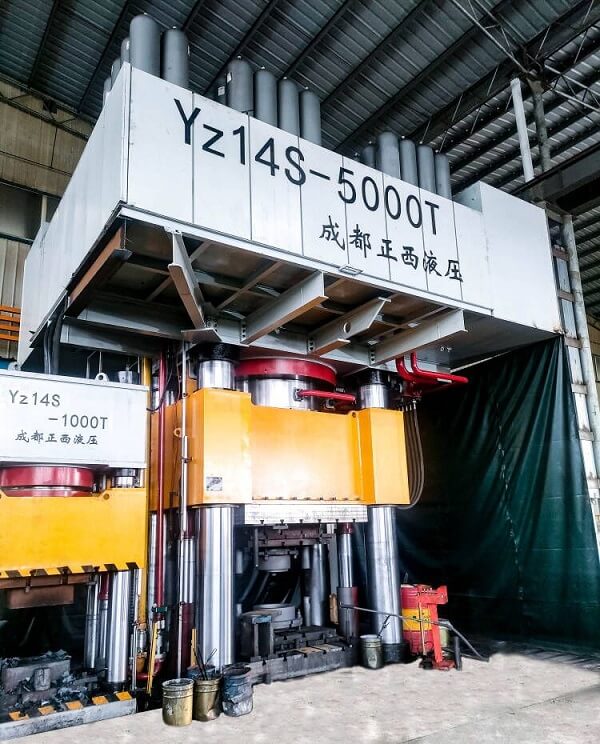

A Mochini o batang oa ho batake lisebelisoa tse ikhethang tsa ts'ebetso e batang ea ho fonyoha, karolo ea eona ea sehlooho ke hore e ka nka tšepe ea tšepe mochesong oa kamore. Mechine e batang ea ho bata hangata e kenyelletsa mochini o batang oa hydraulic o batang o batang le mechini e batang e batang. Mochine o batang o batang o tsamaisa ts'ebetso ea ho fafatsa ka sistimi e kholo, e nang le matla a maholo le ho feto-fetoha le maemo le ho feto-fetoha le maemo a mangata. Mochine o batang oa sefuba o bata o hlokomela mokhoa oa ho theha ka phetisetso ea mochini. Ha e bapisoa le mochini o batang oa hydraulic, matla a eona a ho theha a nyane, empa e na le melemo ea lits'ebetsong tse itseng.

Mochine o chesang ke lisebelisoa tse ikhethang ts'ebetsong e chesang 'me e ka jara tšepe e hlohlelletsa tšepe tlas'a maemo a mocheso o phahameng. Hangata e amohela phetisetso ea hydraulic kapa mochini. Mefuta e fapaneng ea mechini e khethoa ho latela matla a hlokahalang a tlhokoang le litlhoko tsa ts'ebetso. TheMokoloto o chesangE futhumatsa tšepe e kaholimo ho mocheso oa ho boelallization ho e etsa hore e fihle polefalo e ntle ebe e sebetsa ho phethela boemo bo matla.

Ha ho hlahisoa, ho na le mechini e batang e batang ka mechini e chesang le mechini e chesang e bapalang. Mochine o batang oa ho bata o loketse lisebelisoa tsa alloy tse nang le litlhoko tsa polasetiki e tlase le litlhoko tse phahameng haholo. Hangata e sebelisoa ho etsa lipitsa tsa masela a manyane, joalo ka li-bolts, linate tse chesang tse loketseng polasetiki le polasetiki. E ka etsa mesebetsi ea matsoho e boholo le e rarahaneng joaloka likoloi tsa likoloi tsa likoloi le tsa enjine ea Aero.

Ho akaretsa, ho chesa ho bata le ho se thellisa ho hoholo ke mekhoa e 'meli e tloaelehileng ka tšepe ea tšepe. Hape li na le liphapang tsa bohlokoa ka mocheso oa mocheso, mekotla ea lintho tse bonahalang, likokoana-hloko le boholo ba kopo. Ho bata hoa bata ho loketse lisebelisoa tse matla tse nang le foreithela e matla e loketseng mefuta e fapaneng ea tšepe, haholo-holo ba hlokang ho ntlafatsa lelakabe le molomo. Mechini e batang ea ho bata le mechini e chesang ke lisebelisoa tse khethehileng tse sebelisoang ho lemoha mekhoa ena e 'meli. Ba bapala karolo ea bohlokoa tšimong ea ts'ebetso ea tšepe, ba fana ka likarolo tsa tšepe tse phahameng tsa tšepe bakeng sa indasteri e fapaneng.

Zhengxi ke tsebiso e tsebahalangmoetsi oa ho sebetsana le likhatiso Chaena, e fana ka mechini e mengata e batang ea boleng bo holimo le mechini e chesang. Haeba u na le litlhoko, ka kopo ikopanye le rona hang-hang. Litsebi tsa rona li tla u fa lilallo tse phethahetseng tsa hydraulic.

Nako ea poso: Aug-04-2023