1. Ho theha mahala

Ho theha mahala ho bolela mokhoa oa ho sebetsa oa ho sebelisa lisebelisoa tse bonolo tsa Morero kapa ho sebelisa matla a ho tšoaea a se nang letho le tlase sebopeho sa sebopeho sa geometric le boleng ba kahare.

Mahala bakeng sa tlhophiso e lokolohileng e tshwara ho tshwara setlhanyitswang ka batsgeche bo bonyenyane. Ho tšoaea lisebelisoa tse kang ho theha lichisa tsa lits'oaetso le likhatiso tsa Hydraulic ho theha likheo tsa ho fumana lijong tse tšoanelehang. Ho fallisa mahala ho alima mokhoa o chesang oa pherekano.

Ts'ebetso ea mahala ea ho theha mahala e kenyelletsa ts'ebetso ea mantlha, ketso e thusang le ts'ebetso e phethehileng.

Boiteko ba mantlha ba ho thetsa ha li khathatseha, ho phumula, ho bopa, ho hlafuna, ho hlafuna, ho honotha le ho ba le ho qhekella, ho taka le ho oela.

Ts'ebetso ea ho thusa: Ts'ebetso ea Bopaki ba Pele, e kang ho tobetsa mohlahare, e hatellang pheletso ea tšepe ea tšepe, e rema mahetla, jj.

Ts'ebetso ea ho phethela: Ts'ebetso ea ho fokotsa ts'ireletso ea bokaholimo, joalo ka ho tlosa ho hloka chelete le ho ts'oara ho fafatsa.

Molemo:

(1) Ho feto-fetoha ha maemo ho monate ho monate, e ka hlahisa likotoana tse nyane tsa 100KG. Hape e ka hlahisa likotoana tse matla ho fihlela ho 300T.

(2) Lisebelisoa tse sebelisitsoeng ke lisebelisoa tse bonolo tsa moea tse akaretsang.

(3) Ho ikoetlisa ho hohola butle-butle ho potlakela ho se na letho libakeng tse fapaneng. Ka hona, monyaka oa lisebelisoa o hlokang ho foka matla a tšoanang ho feta oa ho shoa.

(4) Litlhoko tse tlase tsa ho etsa lisebelisoa.

(5) Potoloho ea tlhahiso e khuts'oane.

Litsietsi:

(1) Ts'ebetso ea tlhahiso e tlase haholo ho feta ea ho shoa.

.

(3) Basebetsi ba na le matla a mosebetsi a phahameng mme ba hloka maemo a phahameng a mahlale.

(4) Ha ho bonolo ho tseba hore na Mechanaliazation le ho kenella.

2. Shoa

Ho shoa ha ho shoa ha ho buuoa ka mokhoa oa ho tšoarela hore o thehe likheo ka ho etsa likheo tsa lisebelisoa tse khethehileng tsa ho fepa. Ho tšoarela ho hlahisoang ke mokhoa ona ho nepahetse ka boholo, tse nyane tsa tumello, e rarahaneng ka sebopeho le tlhahiso.

Classied ho latela lisebelisoa tse sebelisitsoeng: shoa ho theha mochini oa khatiso, ho shoa ha mochini oa likhomo, ho felisa ho hahlaula mochine o bataletseng, jj.

Melemo:

(1) Ts'ebetso e phahameng ea tlhahiso. Ha botoloa, deformation ea tšepe e etsoa ka thoko ho shoale, kahoo sebopeho se lakatsehang se ka fumanoa kapele.

(2) Ho tšoarela libopeho tse rarahaneng li ka thehoa.

(3) E ka etsa hore mekoloko ea tšepe ea tšepe e na le kahlolo e molemo le ho ntlafatsa bophelo ba tšebeletso.

(4) Boholo ba thekeng li nepahetse haholoanyane, tšobotsi e ntle ho molemo, 'me tumello ea mochini e nyane.

(5) Boloka lisebelisoa tsa tšepe 'me u fokotsa ho seha mosebetsi.

(6) Tlas'a boemo ba litulo tse lekaneng, litšenyehelo tsa likarolo li ka fokotsoa.

Litsietsi:

(1) Boikemisetso ba ho tšoarela bo lekanyelitsoe ke bokhoni ba kakaretso ea ho fepa ka ho fetola lisebelisoa

(2) Potoloho ea ho etsa lintho e shoa e le telele ebile litšenyehelo li phahame.

.

3. Tšela ho theha

Tšela ho thellisa ho bua ka mokhoa o thetsang oo ho ka sebelisoang lintho tse thata tse tsamaeang ka mokhoa o hlakileng ho potoloha

Tšela deformation ea ho leleka ke Deformation e rarahaneng. Boholo ba thepa e holofetseng e phalla ka lehlakoreng le leng le le leng ho eketsa bolelele ba billet, 'me karolo e nyane ea thepa e phalla ka morao ho eketsa bophara ba billet. Nakong ea litsamaiso tsa litsamaiso, sebaka sa karolo ea sefapano sa motsotsoana se fokotsehile ka nako e tsoelang pele. Ts'ebetso ea ho hlokomela moqolo e sebelisa molao-motheo oa ho theha butle-butle ho etsa hore butle-butle e se na letho.

Tšela forga e loketse lits'ebetso tsa sesuli tse kang li-shafts tse fetisang, li hula li-slall, le lisebelisoa tse haufi le tataiso ea bolelele. Tšela ho ka sebelisoa ho hlahisa lithupa tse hokahanyang, li-srenches, li-spikes, limuti, li-spikes, jj.

Ha e bapisoa le ho shoa ha ho tloaelehile, ho thellisa ho na le melemo ea sebopeho sa lisebelisoa tse bonolo, tlhahiso e tlase, boipheliso bo tlase.

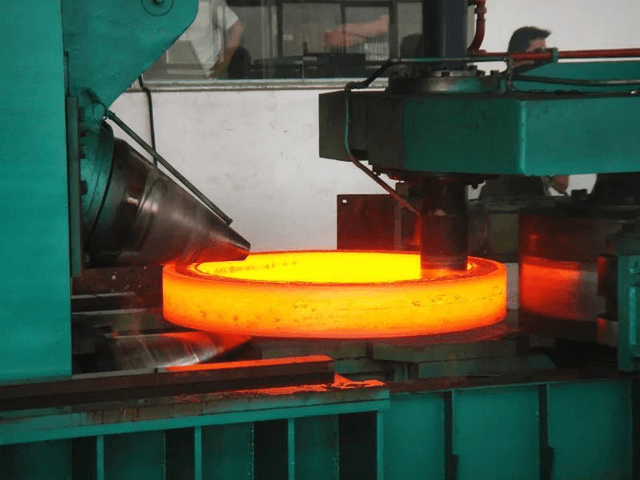

4. Tsire e shoa hape

Tyre e shoa ke mokhoa oa ho lahla ke mokhoa oa ho nyalisa mokhoa oa ho folisa mahala ho etsa se nang letho, ebe o se etsa ka hlobo ea lebitla. Ke mokhoa oa ho theha pakeng tsa ho fosotsoa le ho shoa. E sebelisoa haholo ka likhoebo tse nyane le tse mahareng tse nang le lisebelisoa tse fokolang tsa ho fepa le boholo ba tsona ke li-hammers tsa mahala.

Ho na le mefuta e mengata ea hlobo ea mabili e neng e sebelisoa more, 'me tse sebelisoang ka mokhoa o tloaelehileng ha e etsoa ka mofuta, e benyang, hlobo, hlobo, hlobosa hlobo, joalo-malhieng

Mokhabiso o koetsoeng o sebelisoa haholo bakeng sa ho phalla ha ho tšoarela ha potoloho. Mohlala, lihlekehleke tse nang le babuleng ka linako tse ling li sebelisetsoa ho tšoarela ho iphelisa ka linako tse ling. Sethala se koaletsoeng ho etsa hore ho thehoa ke ho foqoha ha sephiri-mahala.

Bakeng sa tšoarelo ea thapelo ea lebisitsoeng ka libopeho tse rarahaneng, ho bohlokoa ho eketsa lihlomo tse peli tsa halofo) ho etsa sekhobo se kopaneng sa silinda. 'Me nyeoe e thehoa ka mokotleng o entsoe ka limmapa tse peli tsa halofo.

Hangata filimi e hlophisitsoeng e entsoe ka likarolo tse peli, hlobo e holimo le e tlase. Bakeng sa ho tsamaisana le lintho tse holimo le tse tlase ebe li thibela tšoarelo ho tsoa ho feto-fetoha, ho tataisa lipitsa tsa tataiso le tataiso hangata ho sebelisoa bakeng sa maemo. Ho shoa ho ne ho sebelisoa botsitso haholo ho etsa hore re tšoarele ka mefuta e mengata e buang ka libopeho tse tsamaeang, tse kang ho rekisa lithupa, joalo-joalo.

Ha ho bapisoa le ho lahla mahala, thaere ho shoa ho na le menyetla e latelang:

.

(2) Ho tsamaisoa ha lithane tsa marang-rang hoa utloahala, ka hona boleng bo phahame.

(3) Tyre e shoa ho ka lahleheloa ke pherekano ka libopeho tse rarahaneng. Kaha sebopeho sa ho theha se laoloa ke molaoli oa lefu, o thehiloe ka potlako. 'Me tlhahiso e le' ngoe makhetlo a 1 ho isa ho a 5 ho feta ea ho theha.

(4) Ho na le lithibelo tse seng kae, kahoo tumello ea mochini e nyane. Sena ha se tšabe boitsebiso ba tšepe feela empa hape fokotsa lihora tsa matloana.

Litsietsi:

(1) Hamore ea ho fafatsa ka terata e kholo ea hlokahala;

(2) Pholiso e nyane feela e ka hlahisoa;

(3) Bophelo ba tšebeletso ea hlobo ea Tyre e tlase;

(4) Ka kakaretso ke khona ho itšetleha ka basebetsi ba ho tsamaisa hlobo ea thaere nakong ea mosebetsi, kahoo botebo ba basebetsi bo phahame;

(5) Tyre e shoa e sebelisoa ho hlahisa litšebeletso tse mahareng le tse nyane tsa ho tšoarela.

Zhengxi ke tsebiso e tsebahalangHo hlokomela moetsi oa mochini Chaena, e fana ka mefuta e fapaneng ea mechine e fapa-fapaneng, ho kenyelletsa le mechini ea mahala ea mahala, e sebelisa mechini ea ho etsa tlhophiso,Mechine e chesang e fetotsoeng, Mechini e batang e batang, le mechini e futhumetseng ea tlhokahalo, jj. Haeba u na le litlhoko, ka kopo ikopanye le rona.

Nako ea poso: Jun-30-2023