Mokhoa oa ho lieha ke mokhoa oa khale oa tšepe o qalileng ho khutlela ho 2000 BC. E sebetsa ka ho futhumatsa tšepe ho se li finyeletse ka mocheso o itseng ebe o sebelisa khatello ho bo beha sebopeho se lakatsehang. Ke mokhoa o tloaelehileng oa ho etsa hore likarolo tse phahameng li matla, li-le selemo se phahameng. Ts'ebetsong ea taolo, ho na le mekhoa e 'meli e tloaelehileng, mahala e founela le ho shoa ha motho. Sengoliloeng sena se tla hlahloba liphapang, menyetla le likotsi, le mesebetsi ea mekhoa ena e 'meli.

MAHALA

Ho theha mahala, hape ho tsejoa re le hamore ea mahala ea ho fa ea mahala kapa ts'ebetso ea mahala, ke mokhoa oa ho thella ntle le hlobo. Ts'ebetsong ea mahala ea ho theha, ho fafatsa letho (hangata e le moferefere kapa molamu) o futhumatsa sebopeho se batlang joalo ka hara thepa kapa mochine oa khatiso. Ts'ebetso ena e itšetleha ka bokhoni ba basebetsi ba sebetsang, ba hlokang ho laola sebopeho le boholo ka ho sheba le ho bala ts'ebetso ea thetso.

Melemo ea ho theha mahala:

1. Ho feto-fetoha ha maemo

2. Ho boloka thepa ka thepa: kaha ha ho na hlobo, ha ho na lisebelisoa tse ling ho etsa boima.

3. E loketse tlhahiso e nyane ea batch: Ho fallisoa mahala ho loketse tlhahiso e nyane ea batch hobane tlhahiso e mengata ea hlobo ha e hlokehe.

Litsietsi tsa Fording:

1. Ho itšetleha ka litsebo tsa basebetsi: Bophahamo ba ho theha mahala ho latela bokhoni le boiphihlelo ba basebetsi, kahoo litlhoko tsa basebetsi li phahame.

2. Lebelo la ho tlosa butle-butle: Ha ho bapisoa le ho shoa, lebelo la ho lahloa la mahala le tsamaea.

3. Sebopeho sa sebopeho se thata: Ntle le thuso ea hlobo, sebopeho le boholo bo thata le ho hloka ts'ebetso e latelang.

Lipontšo tsa mahala tsa ho theha:

Ho theha mahala ho tloaelehile libakeng tse latelang:

1. Ho etsa mefuta e fapaneng ea likarolo tsa tšepe tse kang ho tšoarela, likarolo tsa hammer le ho lelekeloa.

2. E-ba le matla a phahameng le ho boloka likarolo tse matla tse kang li-crankshafts, li-s cransshafts, lirethe tse tsoang le likarohano.

3. Ho lahla likarolo tsa bohlokoa tsa mochini o boima le lisebelisoa tsa boenjiniere.

Shoa

Shoa ho thellisa ke ts'ebetso e sebelisang tšepe ea ho folisa tšepe. Ts'ebetsong ena, likhechana tsa tšepe li beoa ka hlobo e hlalositsoeng ka mokhoa o khethehileng ebe o beoa sebopeho se lakatsehang ka khatello. Hlobo e ka ba e le 'ngoe kapa e mengata ho latela maemo a rarahaneng a karolo.

Melemo ea ho shoa:

1. Kamohelo e phahameng: Ela hloko e ka u fa taolo e nepahetseng le taolo ea boholo, ho fokotsa tlhoko ea ts'ebetso e latelang.

2. Tlhahiso e phahameng: kaha hlobo e ka sebelisoa makhetlo a mangata, hlobo e loketseng ho loketse tlhahiso e ngata 'me e ntlafatsa ts'ebetso ea tlhahiso.

3. Ho feto-fetoha ha lintho tse ntle: ho senya ho ka netefatsa hore karolo e 'ngoe le e' ngoe e fokotsa ho se tšoanelehe.

Litsietsi tsa ho shoa:

1. Litsenyehelo tse phahameng: Litsenyehelo tsa ho etsa hore hlobo e rarahaneng e phahame haholo, haholo bakeng sa tlhahiso e nyane ea batch, e sa sebetseng litšenyehelo.

2. Ha e tšoanelehe sebopeho se khethehileng: Bakeng sa likarolo tse rarahaneng haholo kapa tse senang meeli, matso a tšoanelehang a tšoanelehang a ka hloka ho etsoa.

3. E sa loketse ho hloleha ka tlase ho mocheso o tlase: shoaloa hangata ho hloka mocheso o phahameng ebile ha o tšoanelehe bakeng sa likarolo tse hlokang mocheso o tlase.

Likopo tsa Dee Forgation:

Ho hlokahala hore ho thelwe sefofaneng se sebelisoa haholo masimong a latelang:

1. Tlhahiso ea likarolo tsa koloi e joalo e joalo ka li-crankshafts, li-discs tsa brake le likuku tsa mabili.

2. Ho etsa likarolo tsa senotlolo bakeng sa lefapha la Aerospace, joalo ka lifofane tsa sefofane, likarolo tsa enjene le likarolo tsa ho laola liqhomane.

3. Eba likarolo tse phahameng tsa boenjiniere tse phahameng tse kang likarolong, li-gears le li-racks.

Ka kakaretso, mahala ho theha le ho shoa ho na le menyetla ea bona le mefokolo ea bona ebile e loketse litlhoko tse fapaneng tsa tlhahiso. Ho khetha mokhoa o nepahetseng oa ho khetha mokhoa o loketseng ho itšetleha ka ho rarahana ha karolo, bophahamo ba tlhahiso le ho nepahala ho hlokahalang. Lits'ebetso tse sebetsang, lintlha tsena li hangata li hloka ho imeloa ho tseba mokhoa o phethehileng. Tsoelo-pele e tsoelang pele le ntlafatso ea lits'ebetso tsa matla li tla tsoela pele ho khanna libaka tsa ts'ebeliso tsa mekhoa eo ka bobeli.

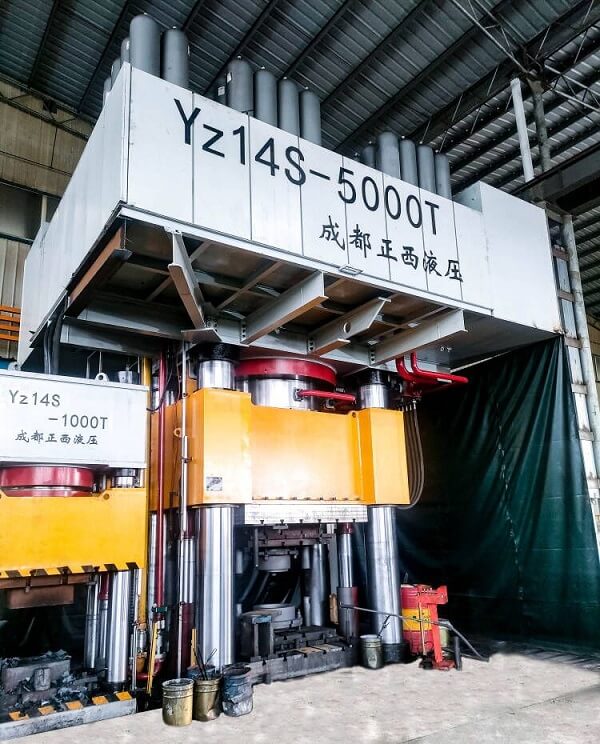

Zhengxi ke setsebiForce's fektheri ea Chaena, ho fana ka boleng bo holimo ba mahalaHo hatella mechine'me u tlohele likhatiso tsa likhotiso. Ntle le moo, likhatiso tsa Hydraulic li ka etsoa le ho hlahisoa ho latela litlhoko tsa bareki. Haeba u na le litlhoko, ka kopo ikopanye le rona.

Nako ea poso: Sep-09-2023