Ho theha lebitso ke lebitso le kopaneng bakeng sa ho theha le ho ts'oasa. Ke mokhoa oa ho sebetsa o sebelisang mothetsi, anvil le ho putlama ha mochini o thetsang kapa hlobo ho etsa hore likarolo tsa polasetiki li fumane likarolo tsa sebopeho se hlokahalang le boholo.

Ho theha eng

Nakong ea ho thellisa, e se nang letho, e se nang letho ea polasetiki ea polasetiki le palo e kholo ea polasetiki. Ts'ebetsong ea matahloko, ho se na letho ho thehile haholo ke ho fetola boemo ba sepakapaka ba sebaka se seng le se seng, 'me ha ho na phallo ea polasetiki e telele ka hare ho eona. Ho theha haholo ho ne ho sebelisoa haholo ho sebetsana le likarolo tsa tšepe. E ka sebelisoa hape ho sebetsa libaka tse ling tse seng tsa boenjiniere, likheo tsa rabara, likubo tsa makhopho, litene le ho theha thepa e kopaneng.

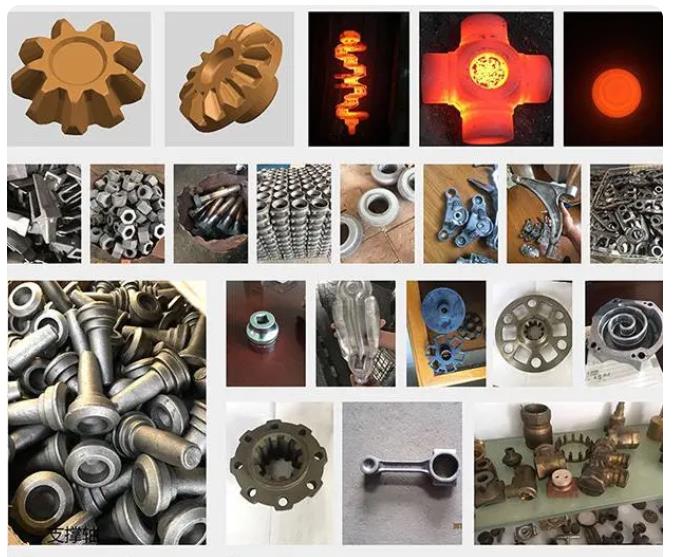

Ho Ronya, ho taka, joalo-joalo. Leha ho le joalo, thekeng e sebelisoa haholo ho hlahisa likarolo tsa tšepe, ha li ntse li sebelisoa ho hlahisa lisebelisoa tsa tšepe tse akaretsang tse kang lipolanete, lipeipi le lithapo le lithapo.

Khetho ea ho theha

Ho theha hangata ho khethiloe haholo ho latela mokhoa oa ho theha mokhoa le mocheso. Ho latela mokhoa oa ho theha, ho thebela ho ka aroloa ka mekhahlelo e 'meli: ho theha le ho ts'oasa. Ho ea ka mocheso oa ho baleha, ho thellisa ho ka aroloa ho chesa haholo, ho bata, ho futhumala, ho futhumala le Innathermal ho itsamaela, jj.

1. Ho chesa ho chesa

Ho chesa ho chesa ho entsoe ka holim'a mocheso oa tšepe. Ho eketsa mocheso o ka ntlafatsang polasetiki, e leng molemo ho ntlafatsa boleng ba kelello le ho bo etsa hore e senyehe. Lithemparetjha tse phahameng le tsona li ka fokotsa ho hanyetsa tšepe le ho fokotsa tonnage ea ho hlokahalaTLHOKOMELISO. Leha ho le joalo, ho na le lits'ebetso tse ngata tse chesang tse chesang, ho nepahala ha mosebetsi ho fosahetse, 'me bokaholimo ha bo boreleli. 'Me litšebeletso li tloaetse ho oxidation, ho lahloa le ho feta, le ho chesa. Ha mosebetsi oa mosebetsi o le o le o le o le o le o moholo le oa polasetiki e nang le matla a maholo le polasetiki ea ho batla li-rods tse boima, e joalo.

Ka kakaretso e sebelisa lithemparetjha tse chesang ke: Carbon Steel 800 ~ 1250 ℃; alloy snede 850 ~ 1150 ℃; lebelo le phahameng tšepe 900 ~ 1100 ℃; a tloaetse ho sebelisoa aluminum 380 ~ 500 ~ 500 ℃; alloy 850 ~ 1000 ℃; Brass 700 ~ 900 ℃.

2. Ho holofala ho bata

Ho foka serame ho bata ho etsoa e etsoa ka tlase mocheso oa tšepe. Ka kakaretso, ho bata ho bolela lintho tse ngata ho bolela ho theha mocheso oa kamore.

Mesebetsi ea mesebetsi e thehiloeng ka ho bata mocheso mocheso oa kamore e nang le tšitiso e phahameng le e nepahetseng, maemo a boreleli, a sebetsang hantle mme a loketse tlhahiso e ikemetseng. Likarolo tse ngata tse batang tse halikiloeng le tse batang li ka sebelisoa ka kotloloho e le likarolo kapa lihlahisoa ntle le tlhoko ea mochini. Leha ho le joalo, nakong ea sefuba ho imelisa, ka lebaka la polasetiki e tlase ea tšepe, ho lisa ho bonolo ho etsahala nakong ea bo-tono.

3. Ho hlapanya ho futhumala

Ho theha mocheso o phahameng ho feta mocheso o tloaelehileng empa o sa fetise mocheso oa ho pheta-pheta. Tšepe e ntse e reriloe, 'me mocheso o futhumetseng o le tlase haholo ho feta oa ho thellisa. Ho futhumatsa ho futhumetse ho na le pono e phahameng, e nang le metsi a boreleli, le ho hanyesa le tlase.

4. ISothermal Fording

Israthermal e thebang e boloka mocheso o se nang letho o lula o le teng nakong ea ts'ebetso eohle e tsamaeang. Israthermal ho sebelisa polasetiki e holimo ka mocheso o mong ka mocheso o le mong kapa ho fumana meaho le thepa e itseng. Mokhooa oa Israthermal o hloka ho boloka hlobo le boitsebiso bo bobe ka mocheso o fokolang, o hlokang litšenyehelo tse phahameng mme o sebelisoa feela bakeng sa lits'ebetso tse ikhethang tsa matlafatso, tse kang subplaring ea Superplace.

Litšobotsi tsa ho theha

Ho qala ho fetola sebopeho sa tšepe le ho ntlafatsa thepa ea tšepe. Kamora hore bengot e be e phethoang, ho lokolloa ha theko ea mantlha, li-pores, likokoana-hloko tsa micros, jj. Baeti ba pele ba robetse, ba ntse ba robetse, ba etsa mabitla. Ka nako e ts'oanang, ho fetoloa ha carbide le ho ajoa hangata ho fetoloa. Etsa junifomo ea sebopeho, ho fumana litšebeletso tse hlokoteloang, junifomo, ho lokile, ho ba le ts'ebetso e ntle ka kakaretso, mme e ka tšeptjoa. Kamora hore thelse e holofetse ka ho chesa ka ho chesa, tšepe e na le sebopeho se mollo. Kamora ho bata ho bata, Crystal ea tšepe e ba e hlophisehileng.

Ho theha ke ho etsa hore ho phalla ha tšepe ho theha mofuta oa sebopeho se lakatsehang. Bophahamo ba tšepe ha boa fetoha kamora ho phalla ha polasetiki e etsahala ka lebaka la matla a kantle, le tšepe li lula li phallela karolong e nyane. Ho hlahiseng, sebopeho sa mosebetsi o laoloa hangata ho latela melao ena ho fihlella mefokolo e kang ho leleka, ho hola, ho inama, ho khumama, ho khumama, le mokhoa oa ho inama, ho khumama, le mokhoa oa ho inama, ho khumama, le mokhoa oa ho khumama, le mokhoa oa ho khumama, le ho taka le setšoantšo se tebileng.

Boholo ba mosebetsi o thehiloeng o nepahetse ebile o etsa ho hlophisa tlhahiso e kholo. Boholo ba lenyalo le theha lits'ebetso tse kang ho theha, ho iphetola, le ho senyeha li nepahetse ebile li tsitsitse. Mechine e phahameng ea ho theha mechini e phahameng le ho fumana chelete ka ho iketsahallang ho ka sebelisoa ho hlophisa boima bo khethehileng kapa tlhahiso e kholo.

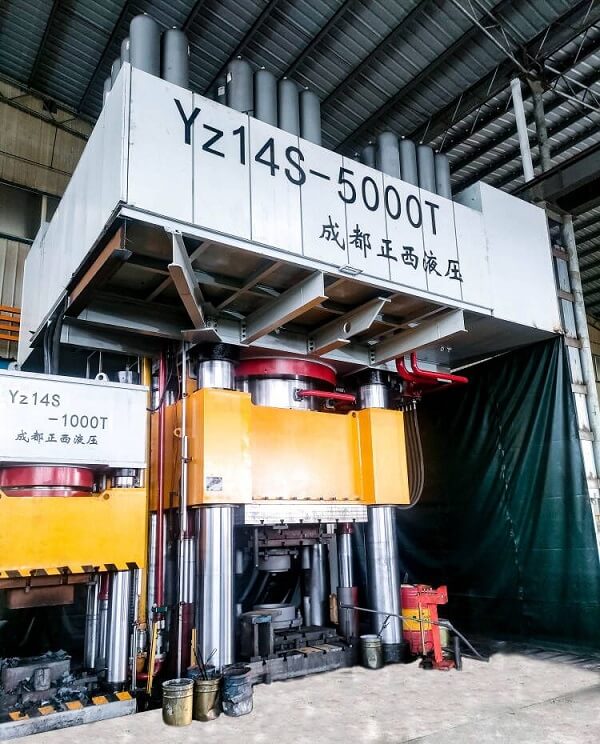

Hangata ho sebelisoa metjello e sebelisoang hangata ho tiisa li-hammers,Lits'oants'o tsa Hydraulicle mechine ea mechine. Hammer ea former o na le lebelo le leholo le nang le tšusumetso, le leng molemo ho phallo ea tšepe, empa e tla hlahisa thoriso. Mochine oa Husralius o sebelisa forling, e leng molemo ho theha tšepe le ho ntlafatsa sebopeho. Mosebetsi oa tsitsa, empa tlhahiso e tlase. Mochine oa mochini oa mochini o na le stroke e tsitsitseng 'me ho bonolo ho kenya tšebetsong mechanization le ho kenella.

Tloaelo ea ntlafatso ea theknoloji

1) Ho ntlafatsa boleng ba likelello tsa likarolo tse felisitsoeng, haholo-holo ho ntlafatsa thepa ea bona (matla, lelapeng, le thata, le matlafatsang) le ho ts'epahala.

Sena se hloka ts'ebeliso ea thuto ea polasetiki ea tšepe. Etsa kopo lisebelisoa ka boleng bo botle ba tlhaho, joalo ka tšepe ea tšepe e rarolloang ka pel'a valum e halikiloeng. Etsa ho futhumatsa pele ho futhumatsa pele ho holisang mocheso oa mocheso hantle. Teko e thata le ho feta ha e silafatsa likarolo tse felisitsoeng.

2) Ho tsoela pele ho lokisa le ho nepahala ha thekeng. Ts'ebetso e sa khaoang ke mokhoa oa bohlokoahali ke tataiso ea bohlokoa ka ho fetisisa khoebong ea mechini ea ho ntlafatsa litšebeletso tse bonahalang, ho ntlafatsa tlhahiso ea mesebetsi, le ho fokotsa matla. Nts'etsopele ea ho futhumatsa lits'ila, hammoho le mekhoa e melelele, bophelo bo bolelele, e leng seriti se sa tsoakoang

3) Ntlafatsa lisebelisoa le ho hlokomela mela ea tlhahiso ea tlhahiso e nang le tlhahiso e phahameng le ho kenella. Tlas'a tlhahiso e khethehileng, tlhahiso ea basebetsi e fokotsehile haholo le ho fafatsa litšenyehelo tse ntlafalitsoeng haholo.

4) Ntlafatsa lisebelisoa tsa ho theha chelete (ho sebelisa theknoloji ea sehlopha, phetoho e potlakileng ea lefu, jj). Sena se nolofalletsa mefuta-futa ea mefuta e mengata, e benyang tlhahiso ea tlhahiso ea tlhahiso ho sebelisa ts'ebetso e phahameng le lisebelisoa tse ikemetseng haholo kapa mela ea tlhahiso. Etsa tlhahiso ea eona le moruo o haufi le boemo ba tlhahiso e kholo.

5) Hlaolela lisebelisoa tse ncha, tse kang ho matlafatsa mekhoa ea ho sebetsana le lisebelisoa tsa metallirgy ea phofo (haholo-holo phofo ea tšepe), lipolanete tsa tšepe tsa masapo, le lisebelisoa tse ling tse matlafalitsoeng. Ntlafatsa The Mahlale Tikenoloji e joalo e le mofuta oa botle ba hae, e leng sebopeho se phahameng le khatello ea maikutlo e phahameng haholo.

Poso: Hlakubele-04-2024