Ouxite Ferrite Magnetitic Hydraulic Press

Likarolo tsa Mochini: Tobetsa (tobetsa (Ho kenyelletsa Seteishene sa Foreine) Mol Frame, sekheo se iketlileng ka ho hlakola mochini.

Whatsapp: +86 176 0282 8986

Litlhaloso tsa motheo tsa tekheniki

1) Sistimi ea lisebelisoa ea gear ea lisebelisoa e sebelisetsoa ho folisa oli ea khatello ho netefatsa khatello ea khatello ho netefatsa khatello, botsitso le ho ts'epahala ha borachanka bo sebelisoa khafetsa.

2) Matla a tlase a matla le ho boloka matla. Ts'ebeliso ea matla ea mochini kaofela e ts'oana le ea tobetsa ea lithahasello tsa 150, 'me tlhahiso ea Shift ke 53% e fetang ea tobetsa ea 150;

3) Sebuti se tloaelehileng se tsepame ho moamoheli, 'me likarolo tse bobupi li ka felisoa kapele ebe se itlamiloe,' me hlobo e ikemetse;

4) 'Mele oa mantlha ke' mele oa tšepe o lahlehileng ka botlalo (kapa oa tšepe e kaholimo le tlase Matla a phahameng a matla, sebopeho se kopanetsoeng, sebaka se senyenyane sa ho kenya, se bonolo bakeng sa ho nka likokoana-hloko kapa tse telele.

5) Yuniti ea mantlha ke sebopeho se seholo sa likopano tse 'ne, se alimang sephutheloana se nang le moea o pholileng o koahetsoeng ke metsi.

6) A sebelisa Screen le sensor ho lemoha semolao ea mochini, ho holofala ho bonolo ebile bo potlakile;

7) Metsoako ea hydraulic ea seteishene sa khatello ea khatello ea maikutlo se phahameng se sebelisa li-valve tsa tekheniki tsa Italy,

8) Khotsofatsa li-slurry tse tlase tsa metsi

Nyeoe ea k'hamphani

Li-paramethara tsa mochini

| Lebitso | Yuniti | Boleng | |

| Mohlala | / | Yf-230t | |

| Matla a holimolimo a mohloa | KN | 2300 | |

| Bophara bo holimo ba silinda | mm | 360 | |

| Moqomo o kaholimo oa mohloa o kaholimo | mm | 495 | |

| Matla a tlase a silinda | KN | 1000 | |

| Bophara bo tlase ba silinda | mm | 250 | |

| Stroke e tlase ea silinda | mm | 145 | |

| Lebelo la Ram | Ho koala | mm / s | >180 |

| Tsela e liehang | mm / s | 2-10 | |

| Ho tobetsa butle butle | mm / s | 0.02-1,5 (e ka fetoloa) | |

| Ho tobetsa kapele | mm / s | 0.1-2.5 (e ka fetoleloa) | |

| Khutla | mm / s | >90 | |

| Lebelo la Ejection | E hana | mm / s | 20 |

| Khutla | mm / s | 35 | |

| Max. sebaka sa mahala sa ho boloka tse holimo le tse tlase | mm | 1080 | |

| Boholo ba mosebetsi (bolelele x bophara) | mm | 1460 × 860 | |

| Sephutheloana sa terata e pholileng | / | Ho khohlela ho khopisoa ke moea ka 100000pere-Turn | |

| Max. Mokhahlelo oa enjene oa pompo ea ente | L | 4.1 | |

| Max. Ho tsamaisa motsoako | L | 180 | |

| 'Muso o felletseng oa mochini kaofela | KW | 65 | |

| Setsi sa Bold | / | 550mm lekhalo pakeng tsa li-oses tsa mold, bophahamo ba 300mm | |

| Nako ea potoloho | S | <60 | |

Pilara

Lipolum tse tataisang (litšiea li tla etsoaC45 e chesang e hlohlora tšepe'me u be le botenya tse thata tsa choating e ka bang 0.08mm. 'Me u etse kalafo e thata le e futhumatsang.

Mmele o ka sehloohong

Moralo oa mochini kaofela o amohela moralo oa ts'ebetso oa k'homphieutha ea k'homphieutha ea k'homphieutha le sekaseka ka ntho e lekantsoeng. Matla le ho tsitsa ha lisebelisoa li ntle, 'me ponahalo e lokile. Likarolo tsohle tsa mochini oa mochini li entsoe ka poleiti ea boleng bo phahameng ea Stered e phahameng ea tšepe

Silindar

| Dikarolo | FHo ja |

| Moriri oa Moriri |

|

| Piston Rod |

|

| Lials | Amopisa Jak Nok Branditing |

| Piston | Taisoa ke ho kenella ka koporo, ho khathala ho hotle ho hanyetsa, ho netefatsa ts'ebetso ea nako e telele ea silinda |

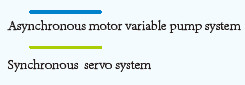

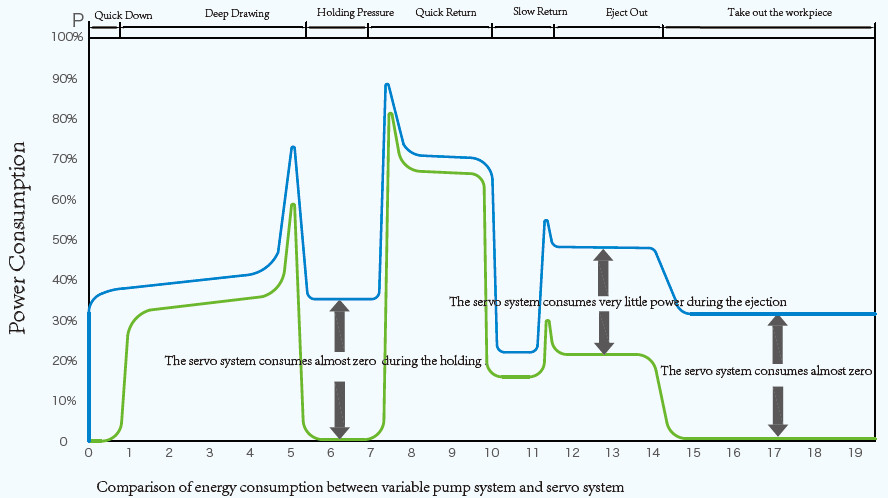

Sistimi ea Servo

1. sebopeho sa sistimi ea sistimi

Molao-motheo oa Taolo ea Ts'ebeliso

Cylinda e ka sehloohong e hlometseng ka kelello ea khatello ea maikutlo, slide e na le sehlopha sa sensor se hlahang. Ho latela lets'oao la maikutlo a khatello, boemo ba maikutlo ba maikutlo, khatello e fanoeng, boemo bo fanoeng ho bala lebelo la setene bakeng sa khatello, lebelo le maemo.

Mochine oa khatiso o amana le ho lokisa khatello le maemo, ka lebelo la koloi ea Ser kokelo ho ea pele taolo e koahetsoeng. Ka ho fetola lebelo la koloi ea Serdano, e ka laola khatello, lebelo le lipala-palo tse ling tsa ho laola khatello ea hydraulic ho ea nolofatsa.

3.dvargers of Servo System

Ho boloka Matla

Ho bapisoa le Sistimi ea Sebopeho sa Great e fapaneng, sistimi ea oli ea ServoHo boloka sekhahla se ka fihla ho 30% -80%.

E sebetsa hantle

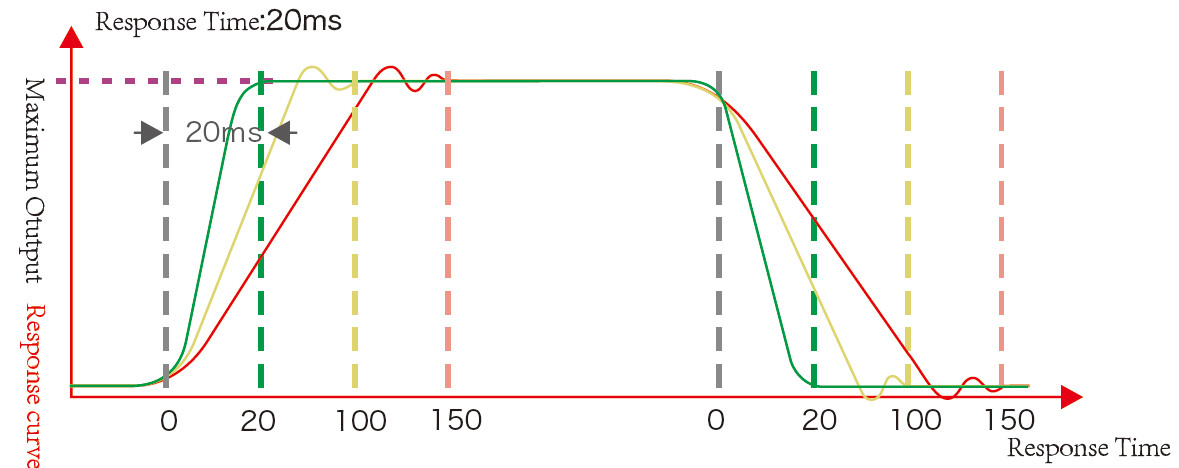

Lebelo la karabelo le potlakile 'me nako ea karabelo e khuts'oane joalo ka 20ms, e ntlafatsang lebelo la tsamaiso ea hydraulic.

Ho nepahala

Lebelo la ho potlaka ho tiisa ho qaleha ho qala le ho koala ka nepo, boemo bo ka fihlela 0.1mm, le boemo bo ikhethang ba ts'ebetso bo ka fihlela ± 0,01mm.

Sephiri se phahameng, seqhetsoana sa algorithm se tiisa khatello ea maikutlo le khatello ea khatello ea khatello ea maemo a tlase ho ± 0.5 BAR, ho ntlafatsa boleng ba sehlahisoa.

Ts'ireletso ea tikoloho

Lerata: Molumo o tloaelehileng oa sistimi ea hydraulic Serdara e 15-20 db e tlase ho feta ea pompo ea mantlha e fapaneng.

Mocheso: Kamora hore tsamaiso ea mehele e sebelisetsoa ka botlalo, e ntlafatsang bophelo ba tiiso ea hydraulic kapa e fokotsa matla a pholileng.

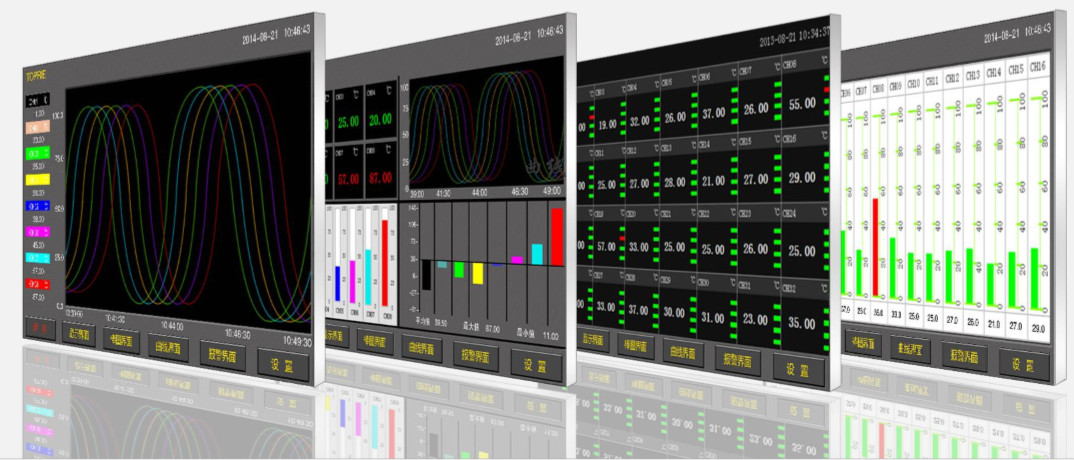

Lenaneo

Sesebelisoa sa lisaete tse ngata tse nang le skrini se hlokomela lipara tsa mantlha le litšusumetso tsa khatiso, haholo-holo ho kenyeletsa tlhahisoleseling e latelang ea tlhahisoleseling:

● Khokahano(MPA, ℃)

| Boemo ba platente, 0 ka botlalo ka botlalo Moea o khathatsang | Cunt City, sethala lenaneong.clam khatello Lebelo

|

Sesebelisoa sa polokeho

Setšoantšo sa Ts'ireletso ea Motlakase: Ka pele

Slice Slicking ho TDC

Ho na le ts'ebetso e peli e sebetsang

Hydraulic tšehetsa potoloho ea inshorense

Tšireletso ea ho jara:

Alamo ea metsi: boemo ba oli

Tlhokomelo ea mocheso oa oli

Karolo ka 'ngoe ea motlakase e na le ts'ireletso e fetang tekano

Mekhaea ea polokeho

Linate tsa senotlolo li fanoa bakeng sa likarolo tse matla

Ketso eohle ea mochine o hatellang Slide e ke ke ea tobetsa ha a sa sebetse. Ha ts'ebetso ea ho loanna e etsahala, ho bontša alamo ho tsoa skrineng sa ho ama le ho bonts'a khohlano.

Sistimi ea Hydraulic

Tšobotsi

1.OIL tanka e hlophiselitsoe ho futhumatsa (ho pholile ke oli ea oli, mocheso oa oli, mocheso oa oli, etsa bonnete ba hore mochini o hatelletse lihora tse 24.)

Ts'ireletso ea HYDRAULIC e alima ts'ebetso e kopaneng ea Carver ea Cartridge Vaves le lebelo le potlakileng le lebelo le phahameng la phetisetso.

3.Ke tanka ea oli e na le sefako sa moea ho buisana le sona ka ntle ho netefatsa hore oli ea hydraulic e sa sitisoa.

4.A khokahano lipakeng tsa valve e tlatsitsoeng 'me tanka ea mafura e sebelisa chelete e ngata ho thibela ho silafatsoa hore e fetisoe ka tankeng ea mafura ebe u rarolla bothata ka botlalo.

5. Malipi oa oli ea hydraulic o entsoe haholo ke phala ea tšepe e sa sebetseng, 'me tsela e kholo ea oli ea bophara e folile. Khokahano ea Pipe e hokahane ke sae flang ka hohle kamoo ho ka khonehang. Ke mofuta o boima oa bo-but o nang le tšusumetso e ntle le o rarollang ka mokhoa o atlehileng ka mokhoa o atlehileng oa ho tlosoa hoa oli ho bakoa ke ho hlonama ho fosahetseng.