Wholesale Price China Smc Water Tank Panel - Automatic SMC Production Line SMC machine sheet molding compound – Zhengxi

Wholesale Price China Smc Water Tank Panel - Automatic SMC Production Line SMC machine sheet molding compound – Zhengxi Detail:

Fully Automatic Resin Mixing Features

1. The control system is controlled by PLC program, which can realize automatic loading.

2. The resin is first put in according to the formula amount set by the program, and is automatically stopped when the formula amount is reached, and then automatically stopped when the low shrinkage agent is put into the formula amount.

3. A resin feed port, a low shrinkage agent feed port and a styrene feed port, a filler feed port are reserved on the Stirring Kettle.

4. The PLC can store multiple different SMC recipes, which can be used by number.

5. Stirring kettle is made of 201 stainless steel for durability.

6. The resin is transported using an imported gear pump or a screw pump with a flow rate of 4-6 cubic meters per hour.

7. Both the Stirring Kettle and the resin storage tank have temperature sensors for monitoring the temperature of the resin paste.

8. The calcium carbonate feed is a vacuum suction conveying method, and the charging time of each calcium carbonate is about 10 minutes.

Fully Automatic Production Line Mixing System Features

1. Composed of three sets of high viscosity gear pumps, mixers and electronic control systems

2. The A, B, and C pumps are driven by servo motors. In the production state, the B and C pumps track the A pump to form a closed-loop control, and are equipped with a mass flow meter with a precision of three thousandths.

3. B, C pump comes with a discharge barrel, the capacity is 100 liters and 50 liters

4. The B and C pumps are all transported by the US Weiken gear metering pump. The A pump uses a Wicken gear pump or an imported screw pump. The A, B, and C pumps are equipped with flowmeters for monitoring the flow rate of the resin paste magnesia paste and the color paste. When any of the components A, B, and C are interrupted, the online system automatically stops.

Parameters

|

Name |

Unit |

Value |

Remark |

|

Name of machine |

|

SMC Production Line |

|

|

Model |

|

SMC-1200 |

|

|

Plastic film width |

mm |

1300 |

|

|

Film Max. diameter |

mm |

400 |

|

|

SMC Sheet width |

mm |

Max. 1200 |

|

|

Productivity |

m/h |

3-700 |

Adjustable |

|

Resin paste viscosity |

Mpas |

10000-35000 |

According to the formula |

|

Fiber content 10%-40% |

According to user needs |

||

|

Blade gap |

mm |

≤0.03 |

|

|

Fiberglass model |

tex |

2400-4800 |

|

|

Number of glass fibers |

1/set |

32-42 |

2 sets |

|

Fiberglass length |

mm |

12.5-25-37.5-50 |

Set by blade |

|

Slicer

|

Set |

2 |

|

|

Fiber dispersion uniform device |

Set |

2 |

|

|

Exhaust device |

Set |

5 |

|

|

Dipping zone speed |

m/min |

3-20 |

Adjustable |

|

Dipping zone mesh belt width |

mm |

1250 |

|

|

Dipping zone length |

mm |

5140 |

|

|

Main motor power |

KW |

4.5 |

Servo motor |

|

Cutting motor |

KW |

2.2*2 |

Servo motor |

|

Winding motor |

KW |

2.2 |

Servo motor |

|

Dimensions

|

mm |

13500 x2400 x2800 |

|

|

Color & MgO Loading method |

Manual |

||

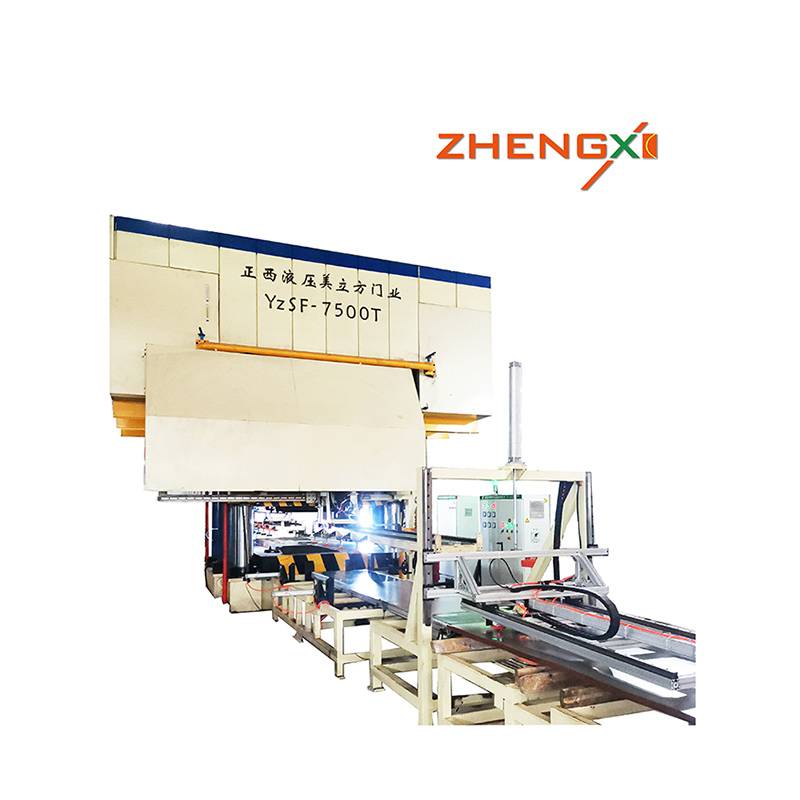

Machine Picture

SMC-1200 Sheet Machine

、 | |

|

|

|

|

|

|

2000L Stirring kettle (2 sets of 22KW motors and 2 sets of reducers)

|

|

|

22KW High Speed Disperser & 150L Mixing Drum(stainless steel)

|

|

|

Automatic Accessories

|

Stirring kettle |

|

Stirring kettle |

|

High speed disperser |

|

High precision flow meter |

|

High precision flow meter |

|

Flow control |

Product detail pictures:

Related Product Guide:

"Quality initially, Honesty as base, Sincere company and mutual profit" is our idea, in order to create repeatedly and pursue the excellence for Wholesale Price China Smc Water Tank Panel - Automatic SMC Production Line SMC machine sheet molding compound – Zhengxi , The product will supply to all over the world, such as: Ghana, Czech republic, Curacao, During in 11 years, We have participated in more than 20 exhibitions, obtains the highest praise from each customer. Our company has been devoting that "customer first" and committed to helping customers expand their business, so that they become the Big Boss !

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.