Wholesale Price Hydraulic Deep Drawing Press - 800T Four-column Deep Drawing Hydraulic Press with Moving workbench – Zhengxi

Wholesale Price Hydraulic Deep Drawing Press - 800T Four-column Deep Drawing Hydraulic Press with Moving workbench – Zhengxi Detail:

1. Main frame:

The frame-type hydraulic machine body is an integral frame structure, composed of steel welded structural parts, with side windows left in the middle of the left and right pillars, using Q355B high-quality steel plate welding structure, carbon dioxide gas shielded welding; after welding, it needs to pass through Annealing treatment fully eliminates welding deformation and stress, ensuring that the welded parts are durable and not deformed, and the accuracy is maintained. The lower beam, pillars, and upper beam are pre-tightened by tie rods (hydraulic pre-tightening) to form a combined frame; there is a sliding block in the middle of the fuselage, and the sliding block is guided by a wedge-type four-corner and octagonal guide rail, and the sliding block guide plate is made of A3+CuPb10Sn10 composite material , The guide rail on the pillar adopts a detachable guide rail.

①Upper beam and bottom beam:The upper beam and bottom beam are welded by Q355B steel plate, and the internal stress is eliminated after welding to ensure the stability of the structure and accuracy of the equipment itself. A main cylinder installation hole is machined on the upper beam. A hydraulic cushion cylinder and a hydraulic cushion are installed inside the bottom beam.

② Pillar: Pillar is welded by Q355B steel plate, after welding, stress relief treatment is carried out. An adjustable sliding block guide block is installed on the pillar.

③Tie rod and lock nut: The material of the tie rod and lock nut is 45# steel. The tie rod is matched with the female lock thread and is pre-tightened by the ultra-high pressure pre-tightening device to lock the body.

2. Slider:

The slider is a steel plate welded box-shaped structure, and the bottom panel of the slider is a whole piece of steel plate to ensure sufficient rigidity and strength. The slider of the frame-type hydraulic press for automobile body car cover forming frame adopts four-corner and eight-sided guide rails. There are 4 sets of guide blocks on the left and right pillars. The guide plates of the slider move vertically on the guide rails, and the movement guidance accuracy depends on the slider guide rails. The inclined iron is used to adjust to ensure the parallelism with the mobile worktable, convenient adjustment, high adjustment accuracy, good accuracy retention after adjustment, and strong anti-eccentric load ability. One side of the guide rail friction pair is made of alloy material, and the other side is made of copper-based alloy material. In addition, the guide rail has been quenched, with a hardness above HRC55, good wear resistance and long service life. The slide rail surface is provided with a lubricating hole for automatic lubrication in order to lubricate the moving parts. The fine adjustment of the slider is realized by the control of the proportional flow valve, which is used for fine adjustment and mold clamping during mold trial selection, and can be adjusted within the range of 0.5-2mm/s.

3. Moving workbench:

The frame-type hydraulic press for forming automobile body shell covers is equipped with a forward moving worktable. The moving worktable is a Q355B steel plate welding structure. After welding, stress relief treatment is carried out. The moving worktable is processed with “T” grooves and ejector holes. The dimensions of the “T” groove and the ejector pin hole are made according to the layout drawing provided by Party A. Leave 400mm in the middle of the “T” groove without milling. Equipped with corresponding ejector rod and dust cover, the heat treatment hardness of ejector rod is above HRC42 degrees. The repetitive positioning accuracy of the mobile worktable is ±0.05mm, and the driving mode is geared with a speed reducer, and it is a self-propelled structure. With the fitting detection device, when the gap between the lower plane of the moving worktable and the lower plane of the bottom beam is greater than 0.3mm, the host is not allowed to work. Provide all mandrel hole covers. There is a cross die slot on the plane of the worktable, the size is 14mm wide to 6mm deep.

4. Main cylinder:

The main oil cylinder adopts a multi-cylinder structure that combines a piston cylinder and a plunger cylinder. The piston rod adopts high-quality carbon structural steel forgings, and the surface is quenched to increase the hardness; the cylinder body adopts high-quality carbon structural steel forgings to ensure the uniformity of materials , The oil cylinder is sealed with imported high-quality sealing ring.

5. Hydraulic cushion cylinder:

A hydraulic cushion cylinder device is installed inside the bottom beam of the frame-type hydraulic press for forming the frame of the automobile body shell cover. The hydraulic cushion has two functions: a hydraulic cushion or an ejector, which can be used to provide a blank holder force during the steel plate stretching process or for eject The product, the hydraulic cushion has a single crown structure, and is equipped with a linear displacement sensor. The press can conveniently realize the digital setting of the stroke conversion position of the slider and the hydraulic cushion, and the operation is simple and practical.

6. Move the worktable to lift the clamping cylinder:

The four lifting and clamping cylinders of the frame-type hydraulic press for automobile body shell cover forming are all piston-type structures. They are installed on the lower cross beam. The movable table can be lifted when it rises, and the movable table can be clamped when it is lowered. Above the lower beam.

7. Buffer cylinder:

A punching buffer device is prepared as required, which is composed of a buffer cylinder, a buffer system and a connected mechanism, and is installed on the upper part of the bottom beam of the press for edge trimming, punching and other punching processes. The buffer cylinder and buffer system can absorb shock and eliminate vibration during the punching process.

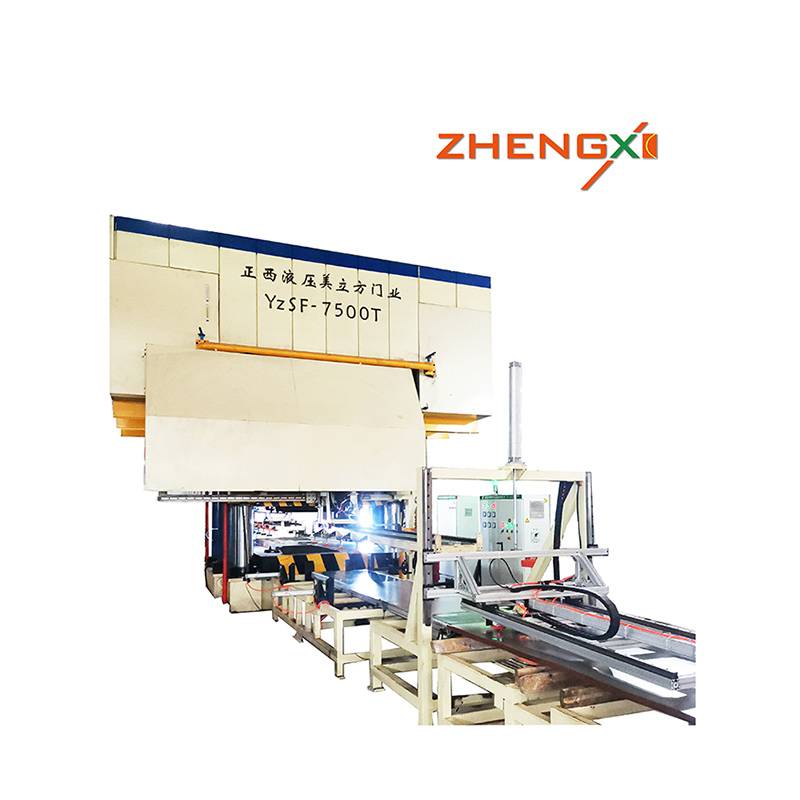

Product detail pictures:

Related Product Guide:

We now have a highly efficient crew to deal with inquiries from clients. Our intention is "100% shopper pleasure by our merchandise quality, price tag & our staff service" and take pleasure in a very good standing amongst purchasers. With quite a few factories, we can easily provide a wide vary of Wholesale Price Hydraulic Deep Drawing Press - 800T Four-column Deep Drawing Hydraulic Press with Moving workbench – Zhengxi , The product will supply to all over the world, such as: Eindhoven, Ecuador, Seychelles, Now the competition in this field is very fierce; but we will still offer best quality, reasonable price and most considerate service in an endeavor to achieve win-win goal. "Change for the better!" is our slogan, which means "A better world is before us, so let's enjoy it!" Change for the better! Are you ready?

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.