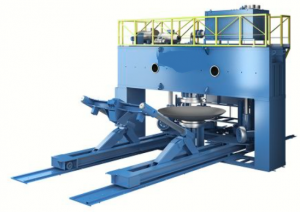

Isitya sokuphelisa umatshini wokushicilela

Intloko ibhekisa kwii-caps zokuphela kweziphelo zombini zesikweri esivaliweyo sensimbi. Yintloko yentloko yesilinda yentsimbi yentsimbi. Licandelo elingenakuthelekiswa nanto kwaye libalulekile kwizixhobo zenqanawa Inxulumene nokusebenza kwexesha elide kunye nokuthenjwa okuxhomekeke kwinqanawa yoxinzelelo. Izinto zentloko yentloko ye-carbon, intsimbi engenasinqwaba, intsimbi engenasinqe, njl njl.

ZhengxiUkushicilelwa kwesitya sokushicilela kuneempawu zokusebenza kakuhle kwemveliso ephezulu kunye nesiphumo esihle sokubumba. Isetyenziselwa ikakhulu iintloko ezicinezelweyo zeelori ezahlukeneyo zeetanki, kwaye zinokusetyenziselwa ipleyiti ephakathi nelincinci, zolula, ukulungiswa, kunye nezinye iinkqubo ezikumgangatho weparameter. I-7000 yeetoni, iitoni ezingama-2000, iitoni ezingama-2000, iitoni ezingama-4000, kunye neetoni ezingama-9000, njl njl.Isitya sokuphelisa umatshini wokushicilelas zolunye nkcazo ngokweemfuno zabathengi.

Izibonelelo ze-5000-ton dish dish iphephe yoomatshini oomatshini:

1. I-fuselage yamkela imitshato emine ye-Beam kunye nendawo ezinemathomu ezine kunye nengqongqo eqinileyo. Isikhokelo sesilayidi samkela isakhiwo esibekiweyo kwaye sikhokele ngokuchanekileyo.

2. Ukutshixwa kwe-natity kunesakhiwo esichasene nokugcinwa ngokuchanekileyo. IcinezelaIxhotywe ngepali esezantsi ye-hydraulic kunye nentonga engaphezulu.

I-3. Iisilinda zeoyile zonke zisebenzisa izinto zokutywina okungeniswayo ukuqinisekisa ukusebenza ngokuthembekileyo.

I-4. I-piston rod yenziwa malunga ne-carbon ekumgangatho we-carbon berbon ngonyango lwe-pileching. Intloko ye-piston yamkela ulwakhiwo olubalulekileyo, olukhuselekileyo kwaye luthembeke ngakumbi kunentloko ye-piston ye-piston.

5. Ulawulo lwe-hydraulic kunye ne-elektroniki luhlanganiselwe kwaye zafakwa, amaphephandaba ehlala indawo encinci, imbonakalo intle, kwaye ufakelo loshicilelo aludingi mgodi.

I-6. Ulawulo lwe-hydraulic yamkela inkqubo yeCartridge Valve Valve, enokuthenjwa isebenza kwaye ilula ukuyigcina.

7. Uxinzelelo lokusebenza kunye nokuSebenza kokuSebenza kolu shicilelo lokupheliswa kwesidlo kunokulungiswa ngaphakathi kwenqanaba leparameter ngokweemfuno zokusetyenziswa.

I-8.

9. Isixhobo solawulo lwe-elektroniki sinokuqonda ukuphakamisa kunye nokugquma kwe-windows yenqe kwaye ingenise ngaphakathi nangaphandle kwe-fusselate.

10. Ixhotywe ngenkqubo yolawulo eguqukayo apho amajoni e-tensle anyukayo, etshintsha i-hard forters, etshintsha i-scoper yoochwephesha kwentloko yentloko. Ngokusebenzisa ulawulo oluguqukayo ukuba amajoni e-tensle anyukayo angenamsebenzi ongenanto, i-culls efanelekileyo yolwandiso lokwanda kwepleyiti ebandayo ilawulwa.

11. IIsitya sokuphelisa umatshini wokushicilelaIxhotywe nge-gamder pay kunye ne-tensle beam. Ngexesha lenkqubo yolula, amandla e-tensle kunye ne-Grensce Dolder ahlengahlengiswa ngokulinganayo kuluhlu lwe-0 ukuya kwi-25mpa ngokweemfuno zenkqubo.

Iindidi zoomatshini bokuyigqibela kwesitya

I-1. I-Hot Poina Presh Shicil Shiciulic cinezela

Ingxamisekile kwaye iyaguquguquka kuluhlu lwesicelo, inezinto eziphakamileyo zokuvelisa, kwaye inoqoqosho kwaye ziyasebenza.

■ Kufanelekile kwi-HED yeNtloko yeNtloko yeNtloko

■ Ulwakhiwo lweendaba

■ Isilayidi esibanjiweyo sixhotywe nge-adaptha eshukumayo

■ Ukubetha kwe-cylinder ye-Holder iguqukile

■ Amandla oNcedo olungenanto kunye namandla owolula anokuhlengahlengiswa ngokuzenzekelayo

■ inokuqonda isenzo esinye kunye nesenzo esiphindwe kabini

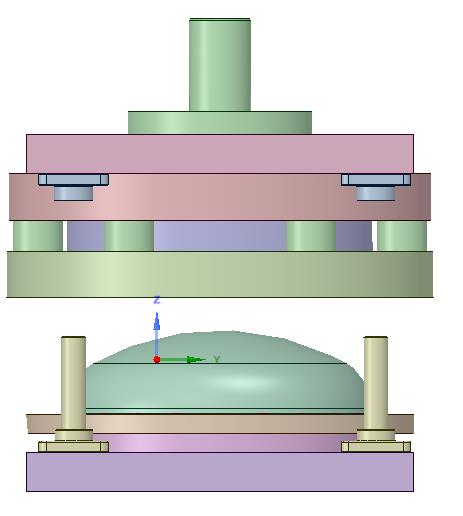

I-2. I-Councia ye-Grand Dissh Shiciulic cinezela

■ Kufanelekile kwi-Councia yeNtloko yeNtloko

■ Ulwakhiwo lweendaba

■ Umatshini woLwandle uxhotywe nge-mold ephezulu, i-mold esezantsi, uqhagamshelo lwe-MALD, kunye nesixhobo sokutshintsha ngokukhawuleza

■ Amandla oNcedo olungenanto kunye namandla owolula anokuhlengahlengiswa ngokuzenzekelayo

Iiparamitha eziphambili zoomatshini wokushicilela

| Iiparamitha eziphambili | Iyunithi | Ixabiso lamanani | |||

| Amandla otyunjiweyo | KN | 20000 | 50000 | I-100000 | |

| Uxinzelelo lwamanzi | Mpa | 90 | 78.5 | 60.5 | |

| Isilayidi | mm | I-300 | I-400 | I-800 | |

| Isantya seSlider | Imvelaphi ekhawulezayo | mm / s | 10 | 40 | 60 |

| Umsebenzi uqhubela phambili | mm / s | I-1-1.5 | 0.6 | I-0.2-0.3 | |

| Ukubuyela kuhambo | mm / s | 20 | I-100 | I-100 | |

| Ukuphakama okuphezulu | mm | I-700 | I-1100 | I-2500 | |

| Ubuncinci bokuphakama | mm | I-400 | I-700 | I-1700 | |

| Inkalo esebenzayo ye-Ordedch (ngasekhohlo nasekunene * ngaphambili nangasemva) | mm | I-1030 x 800 | I-1200 x 1200 | Ngo-2000 x 2000 | |

| Amandla eemoto | KW | 30 | 45 | I-220 | |

| Imilinganiselo yomatshini (ngaphambili nangasemva * ngasekhohlo nasekunene * ukuphakama) | mm | I-1430 x 800 x 3650 | Ngo-1940 x 1200 X4683 | I-2000 x 3060 x8000 | |

Zhengxi yingcaliI-Hydraulic Prefic Prefic e Chinakwaye unike umatshini wokushicilela ophezulu. Ukuba unazo naziphi na iimfuno, nxibelelana nathi!