I-powder yensimbi yenza umshicileli we-hydraulic

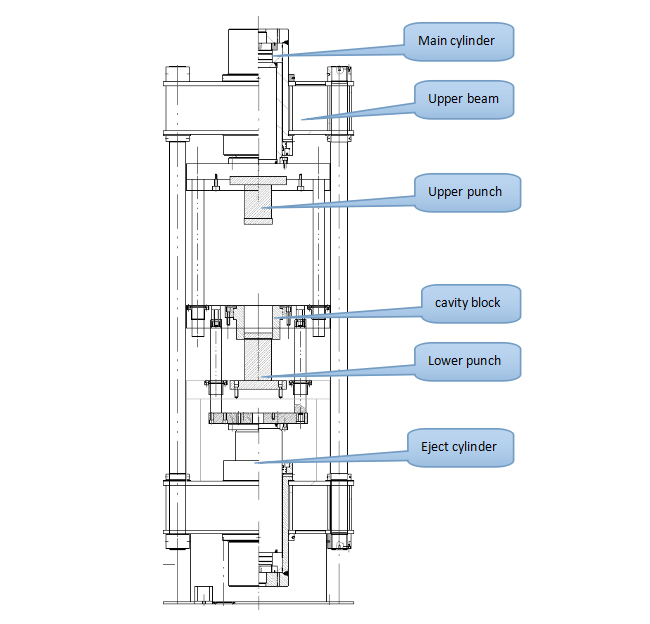

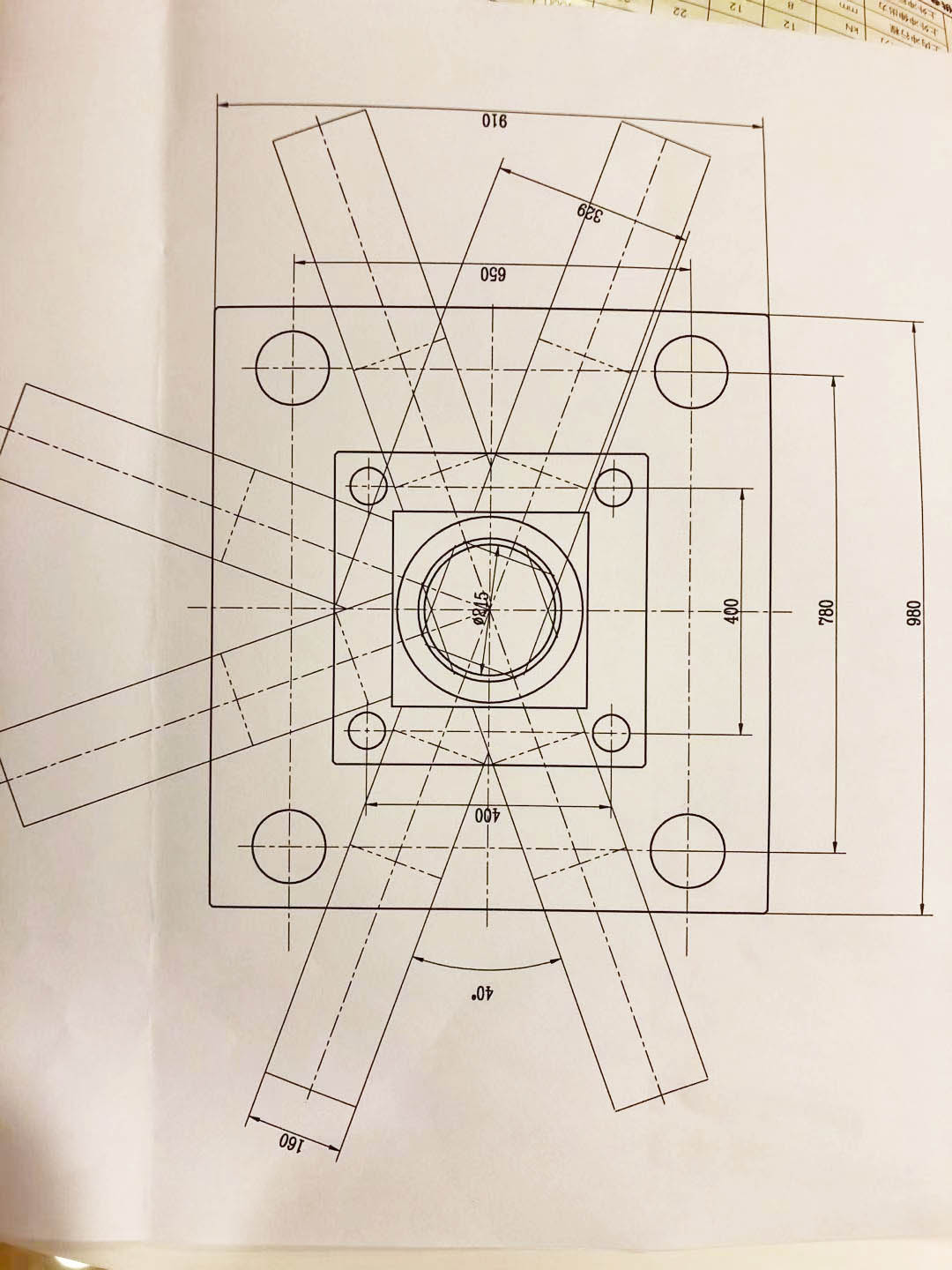

Isakhelo sokubumba

I-1) Isiseko sobumba senziwe ikakhulu nge-8CRCR kunye nentsimbi ye-45 # intsimbi ngokunyanzelwa, ukujika kunye nokubi okubi ukuqinisekisa ukuba sichanekile intsimbi eyoneleyo kunye nokuchaneka kwentsimbi eyoneleyo kunye nokuthengiswa kwentsimbi. Esi sikhokelo sibe ngumsebenzi wokwahlukana ngezinto zokukhusela umphezulu kwi-abrasion, njengokukhokelwa kobhedu. Nge-cr.

I-2) Inxalenye ephezulu yesakhelo seflethi yi-punch enye ephezulu, kwaye i-punch ephezulu ilungisiwe ngokuthe ngqo kwi-punch ephezulu; Ibhinqa lesibumba ilungisiwe kwitemplate engeyiyo, kwaye zombini uxinzelelo olusebenzayo kunye nokucinezelwa ngokunyanzelwa kwenziwa kwinkqubo yokucinezelwa. Ukukhetha ngokungacwangciswanga, "i-PACMIRD", ukucinezelwa kokudada, uxinzelelo lwexabiso lokulibaziseka, ukulibaziseka koncedo, njl njl. Xa ususa umgubo, indawo ephezulu kunye nezantsi edadayo i-smlds ifakwe ngokungqinelana ngokuhambelana ne-punch ephezulu.

I-3) Indlela yokudinga inenkululeko ngokubanzi kunye nokukhusela ukutya kukhuseleko; Ibhinqa le bhinqa kunye ne-ERTOTONITATAL NASEKHAYA NOBUCHULE BUYAQHUTYELWA UKUZE UVULE UKUKHANGELA UMBULELO, kwaye ukukhululwa kwe-mold esebenzayo ye-GORD ye-GORDS ukuba ingonakali.

4) Ukondla ukuphakama, imveliso ecinezela ukuphakama kunye nokusebenza kwenkululeko yokusebenzisa inzululwazi yokufuduka kwenkqubo kunye nokuchaneka kwenkqubo ye-PLC, kunye nomda wesixhobo sobuchwephesha.

I-5) i-on-metriver ye-on-metricac ifakwe kwiNtlawulo yePlasta yokudada kunye nebhloko ye-Cavity, kwaye izinto ezingezizo ezingezizo zentsimbi, kwaye zonke izinto zensimbi azikwazi ukunxibelelana nomgubo wensimbi.

Inkqubo yokondla

Inkqubo yokondla iya kuba nee-hoppers ezi-6, kwaye i-hopper nganye iya kulayisha izinto ezahlukeneyo eziluhlaza.

2.I-hopper inokuhanjiswa, kwaye itywine kakuhle.

3.Ukulayishwa kwezinto ezingafunekiyo, qho kwimivumbo emi-5 ukuya kwezi-5.

Ubuninzi bokusebenza kwe-4mPPR bunokusetwa kwi-HMI, i-1,2,3 ... 10, ngokusebenzisana.

5.6 Ii-hoppers ezinkulu ziya kufakelwa ngaphezulu komatshini, i-hopper nganye inokulayisha i-15 kg yomgubo.

Intsika

Iikholamu zesikhokelo (iintsika) ziya kwenziwaI-C45 ishushu intsimbi yentsimbikwaye ube ne-chrome enzima ye-chrome i-0.08mm. Kwaye wenze lukhuni kwaye unyango.

Imigangatho yemveliso

I-JB / T3818-99"Iimeko zobugcisa ze-hydraulic cinezela"

GB5226.1002"Ukukhuseleka komatshini-umatshini kunye nezixhobo zombane - Icandelo 1: Iimfuneko zobuGcisa ngokubanzi"

GB / T 3766-2001"Iimfuneko zobugcisa ngokubanzi kwiinkqubo ze-hydraulic"

GB17120-97"Cinezela uMdibaniso wokhuseleko"

Jb967-99-99"Umda we-hydraulic umda wengxolo"

Umzimba ophambili

Uyilo lwalo matshini uphela uyayime i-Computer Applisotion yoyilo kunye nohlalutyo ngenqaku eligqibeleleyo. Amandla kunye nobungqola bezixhobo zilungile, kwaye imbonakalo intle. Zonke iindawo zedilda ze-Welding zidlwengulwe yi-Wieel Mill Mill Q345B Playiti, eDelid ngekhabhoni ye-Carbon ukuqinisekisa umgangatho we-welding.

Isilinda

| Amalungu | Fukutya |

| I-cylinder barrel |

|

| Piston rod |

|

| Amatywina | Ukwamkela uMgangatho weNqaku loMgangatho wokutywina |

| Piston | Ukukhokelwa ngubhedu ngobhedu, ukunyangwa okuhle, qinisekisa ukusebenza ixesha elide ngesilinda |

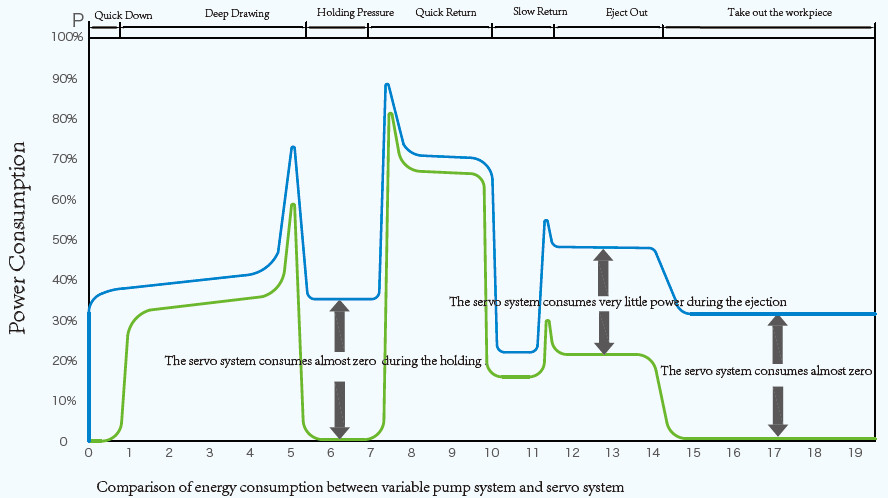

Inkqubo ye-servo

I-1.Nerservo yenkqubo

I-Broody yenkqubo ye-servo

Ukugcina amandla

Xa kuthelekiswa nenkqubo yempompo eyahlukileyo, inkqubo ye-Insevo ye-oyile idibanisa imizobo yesantya ekhawulezileyo ye-serno kunye nokulawula amandla e-oyile ye-hydraulic, kunye namandlaIxabiso logcino linokufikelela kwi-30% -80%.

Ngokufanelekileyo

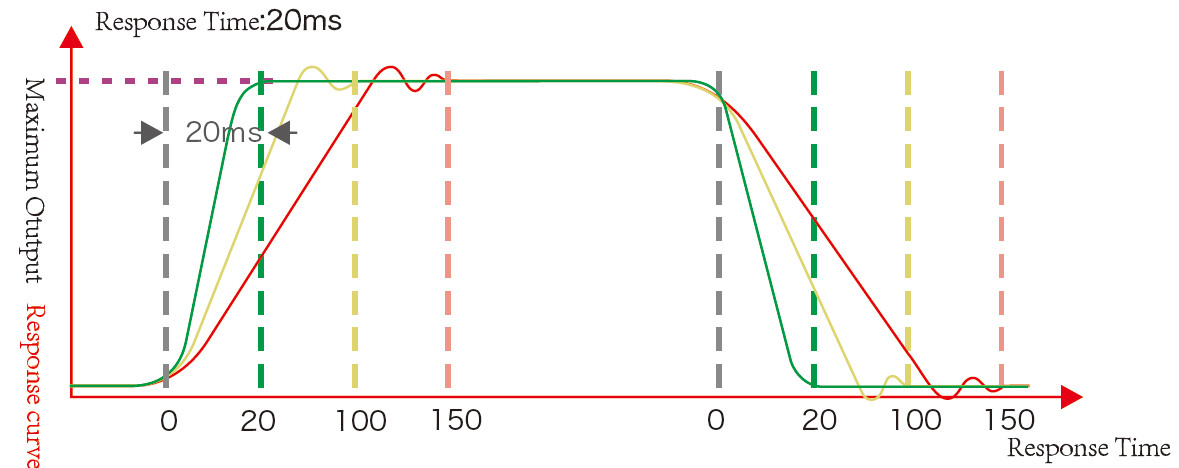

Isantya sokuphendula sikhawuleza kwaye ixesha lokuphendula lifutshane njenge-20ms, eliphucula isantya sempendulo senkqubo ye-hydraulic.

Ukuchaneka

Isantya sokuphendula ngokukhawuleza siqinisekisa ukuchaneka nokuvalwa kokuvula, ukuchaneka kwendawo kungafikelela kwi-0.1MM, kunye nendawo ekhethekileyo yokusebenza± 0.01mm.

Imodyuli ephezulu ye-algorithm iqinisekisa uxinzelelo lwenkqubo oluzinzileyo kunye noxinzelelo lokuguquguquka okungaphantsi± 0.5 bar, ukuphucula umgangatho wemveliso.

UKUKHUSELEKELA KWESICELO

Ingxolo: Ingxolo yengxolo ye-hydraulic senso yenkqubo ye-15-20 DB iphantsi kunelo mpompo yokutshintsha.

Iqondo lokushisa: Emva kwenkqubo ye-servo isetyenziswa, iqondo lobushushu le-hydraulic lincitshisiwe lilonke, ephucula ubomi betywina le-hydraulic okanye inciphise amandla okupholisa.

Isixhobo sokhuseleko

I-Photo-Short-Umbane woMbane

Ukutshixwa kwesilayidi kwi-TDC

Umsebenzi ombini wezandla

Isekethe ye-Inshurensi ye-Hydraulic

Ukukhuselwa okungaphezulu: I-Valve Erveve

I-Alarm yenqanaba le-wolity: inqanaba leoyile

Isilumkiso seqondo lobushushu leoyile

Inxalenye nganye yombane ilayisha ngaphezulu

Iibhloko zokhuseleko

Izitshixo zinikezelwa kwinxalenye eshukumayo

Lonke inyathelo lokushicilela lunemisebenzi yophuhliso lokhuseleko, umz. Ukususwa kwemali akuyi kusebenza ngaphandle kokuba i-caushion ibuyela kwisikhundla sokuqala. Isilayidi asinakucinezela xa kunyanzelekile ukuba inyanzeliswe. Xa umsebenzi wengxabano yenzeka, i-alamu ibonisa kwiscreen sodidi kwaye ibonise ukuba yintoni impikiswano.

Inkqubo ye-hydraulic

I-1.oil Itanki ihlawulwe inkqubo yokuphola i-Filting (isixhobo sokupholisa amasebe emizi-mveliso, ukupholisa ngokujikeleza amanzi, ubushushu be-oyile55 ℃, umatshini wokuqinisekisa ukuba ucinezela ngokuqinileyo kwiiyure ezingama-24.)

Inkqubo ye-Hydraulic yamkela inkqubo yokulawula i-velidge ye-velidge yesantya sokuphendula ngokukhawuleza kunye nokusebenza okuphezulu.

3.Itanki yeoyile ixhotywe ngentloko yomoya ukunxibelelana ngaphandle ukuqinisekisa ukuba ioyile ye-hydraulic ayingcolwanga.

4.Unxibelelwano phakathi kwevalve yokuzalisa kunye netanki yamafutha isebenzisa i-cuntry edibeneyo ukuthintela ukuntywila kwitanki yamafutha kwaye isombulule ngokupheleleyo ingxaki yokuvuza ioyile.