Isiphelo sesiphelo sisigqubuthelo sokuphela kwinqanawa yoxinzelelo kwaye zezona zinto ziphambili zoxinzelelo kwinqanawa yoxinzelelo. Umgangatho wentloko unxulumene ngokuthe ngqo nokusebenza kwexesha elide kunye nokuthenjwa kwenqanawa yoxinzelelo. Yinto engenakuphikiswa nebaluleke kakhulu kwaye ibalulekile kwizixhobo zenqanawa zoxinzelelo kwi-petrochemicals, amandla e-Atomic, ukutya, amayeza, kunye namanye amashishini amaninzi.

Ngokuphatheni, iintloko zinokwahlulahlulwa zibe ziintloko ezicawa, iintloko ezinomthi, iintloko ze-oval, kunye neentloko ze-SPhering. Iintloko zeenqanawa zoxinzelelo oluphezulu kunye nee-boilers zininzi kakhulu, kwaye iintloko ze-oval zisetyenziselwa uxinzelelo oluphakathi nangaphezulu. Inani elincinci kuphela leenqanawa zoxinzelelo eziphantsi zisebenzisa iintloko-ezimile.

I-1. I-Dissh-Ukuphelisa indlela yokuphelisa

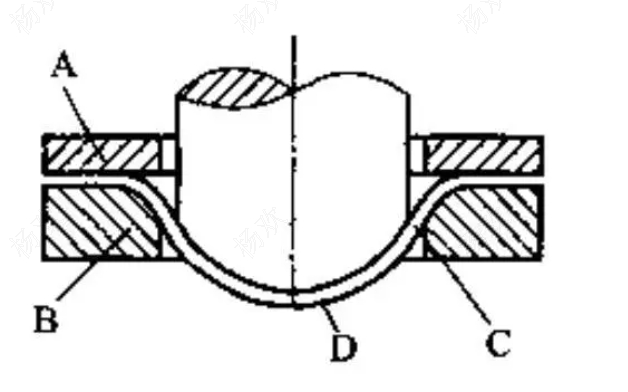

(1) ukubetha. Ukuziqhelanisa nemveliso yobuninzi, ukucinezela iintloko ze-gened kunye ne-seamer-encinci ifuna iiseti ezininzi zentloko.

(2) Spin. Ilungele iintloko ze-ultra kunye ne-Ultra ezinqabileyo. Ingakumbi kwishishini lekhemikhali, elibandakanya ukusebenza kakhulu kunye ne-sub-sub-sub. Iintloko ze-oval zilungele kakhulu ukujikeleza, ngelixa iintloko zokuhlanjwa azifane zisetyenziswe kwaye iintloko ze-scherical zinzima kakhulu ukucinezela.

2. Isixhobo seNtloko yeNtloko kunye nezixhobo

(1) Izixhobo zokufudumeza: isitovu segesi. Iziqitha zokuhlola iziqitha ngoku zisetyenziselwa ukufudumeza, kwaye i-oyile okanye i-head yokufudumeza isetyenziswa kangangoko kunokwenzeka. Kuba ibonakaliswa yi-quimbation ecocekileyo, ukusebenza kakuhle, ulawulo lobushushu olulula, kunye nobunzima bokwaphula umthetho kunye nokuphatha. Izithando zokufudumeza kufuneka zixhotywe ngesixhobo sokulinganisa ubushushu kunye nomphathi wobushushu

.

(2)Cinezela cinezela. Zimbini iintlobo: isenzo esinye kunye nezenzo ezimbini.

Intshukumo enye ithetha kuphela isilinda esinqwenelekayo kwaye akukho silinda singenanto. Zimbalwa kuphela iifektri ezincinci nezezisiseko eziphakathi. Iifektri ezinkulu zonke zisebenzisa inyathelo eliphindiweyo, oko kukuthi, kukho isilinda esingenanto kunye nesilinda esifumileyo.

Indlela yokuhambisa ye-hydraulic ngamanzi. Ixabiso eliphantsi, ihamba ngokukhawuleza, alizinzanga, kwaye alinazimfuneko zokutywinwa okuphezulu njengoMatshini we-hydraulic. Ukusebenza kakuhle kwezantsi kuneI-Hydraulic cinezela, kwaye iimfuno zesikhokelo azingqini. Ukuhanjiswa komshicileli we-hydraulic kuyazinza kwaye uneemfuno eziphezulu zokutywina kunye nesikhokelo.

(3) Sebenzisa izixhobo, kubandakanya iintlobo ezahlukeneyo zeNtloko zeNtloko zeNtloko kwaye zisezantsi kunye neeNkxaso, njl.

I-3. Izinto ezichaphazela udonga oluqinileyo lwentloko

Izinto ezininzi zichaphazela utshintsho entloko, olunokushwankathelwa ngolu hlobo lulandelayo:

(1) Iipropathi zezinto ezibonakalayo. Umzekelo, isixa esincinci sentloko yetywina sikhulu ngakumbi kunentloko ye-carbon yokutywina.

(2) Ubume bentloko. Intloko ene-discd inesixa esincinci sokutyibilika, intloko ye-spherical inesona sixa sikhulu sokuthintela, kwaye intloko ye-elliptical inemali ephakathi.

.

.

.

.

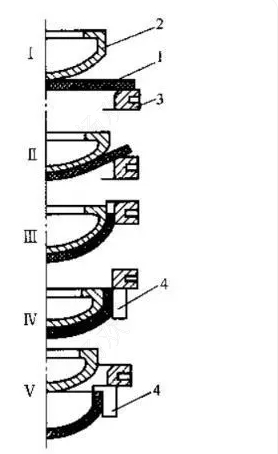

4. Cinezela kwaye wenze ifom thUkuphela kwesihlahla

(1) Ngaphambi kokuba intloko nganye icinezelwe, isikali se-oxaden entloko kufuneka isuswe. I-Lubricant kufuneka ifakwe kwi-mold ngaphambi kokuzimasa.

. Isiphambuka kwiziko phakathi kwento engenanto kwaye i-mold esezantsi kufuneka ingaphantsi kwe-5mm. Xa ucinezela intloko eshushu, ingqalelo kufuneka ihlawulwe ukubeka ukuvulwa kwe-elliptical kwindawo engenanto kwindawo enye kunye ne-axes ende nefutshane. Ngexesha lenkqubo yokucinezelwa, kuqala, lungelelanisa i-hole punch kunye nendawo yokuvula yento engenanto kwaye ityhala ngaphandle. Tyhala kangangendawo engaphezulu kweplanethi ye-mold engezantsi (malunga ne-20mm), emva koko cinezela ubumba ophezulu. I-hole punch iwa iwela ngaxeshanye ukucinezela intloko ibe yimbonakalo. Ngexesha lokucinezela, amandla atyhutyhayo kufuneka anyuke kancinci ade aye kuphakame kwaye anganyuswa okanye anciphise ngequbuliso.

. Musa ukuyibeka kwi-vent. Sukuzifaka ngaphezulu kwamaqhekeza amabini ngaphezulu kwelinye ngaphambi kokupholisa kubushushu begumbi. Ngexesha lokuqhubeka kwesitampu, iqondo lokushisa lokufa liphuma lingamalunga ne-250 ° C kwaye isitampu akufuneki siqhubeke. Umsebenzi unokuqhubeka kuphela emva kokuba kuthathwe amanyathelo okupholisa ukunciphisa ubushushu babantu bafa.

(4) Intloko evuthayo kufuneka yenziwe kwinyathelo elinye kangangoko kunokwenzeka. Xa kungenakwenzeka ukuba senze ixesha elinye ngenxa yezithintelo ezinemiqathango, ingqalelo kufuneka ihlawulwe kubuchule nentloko xa ihlanjwa umngxunya, kwaye kufuneka ihlawulwe ukugcinwa komngxunya weflethi.

5. I-HORD ishushu intloko yecinezela i-hydraulic

Ingxamisekile kwaye iyaguquguquka kuluhlu lwesicelo, inezinto eziphakamileyo zokuvelisa, kwaye inoqoqosho kwaye ziyasebenza.

■ Kufanelekile ukuba i-cinezela yentloko eshushu.

■ Isakhiwo seendaba

■ Isilayidi esibanjiweyo sixhotyiswe nge-adaptha eshukumayo.

■ Ukubetha kwe-clight ye-Holder ingena kulungiswa.

■ Amandla omsebenzisi angenanto kunye namandla owolula anokuhlengahlengiswa ngokuzenzekelayo.

■ unokuqonda isenzo esinye kunye nesenzo esiphindwe kabini.

I-6. Ukucinezelwa kwentloko yentloko yokwakha i-hydraulic cinezela

■ Kufanelekile ukubandezeleka kweentloko zentloko.

■ Isakhiwo seendaba

■ Umatshini woLwandle uxhotywe nge-velop ephezulu, ongezantsi onxibelelana, kunye nesixhobo sokutshintsha ngokukhawuleza.

■ Amandla omsebenzisi angenanto kunye namandla owolula anokuhlengahlengiswa ngokuzenzekelayo.

Ixesha lokuposa: I-Mey-09-2024