I-1. Ukuphawula ngokukhululekileyo

Ukunyanzelwa simahla kubhekisa kwindlela yokusebenzisa izixhobo ezilula zenjongo okanye ukusebenzisa amagunya angaphandle kwibala lemigangatho ephezulu kunye nezixhobo zejometri kunye nomgangatho wangaphakathi.

Ukuqhutywa simahla ngokukhululekileyo kuvelisa ukuxolela kwiibatch ezincinci. Izixhobo zokwenza ukuba zenza izando zehati kunye noomatshini bokushicilela be-hyddraulic basetyenziselwa ukwenza izinto ezingenanto ukufumana okuzimeleyo. Ukutyholwa ngokukhululekileyo yamkela indlela eshushu.

Inkqubo yokufowuna yasimahla ibandakanya inkqubo esisiseko, inkqubo encedisayo, kunye nenkqubo yokugqiba.

Inkqubo esisiseko yokuzibandakanya siyikhathaza, tsala, ukugoba, ukugoba, ukujija, ukutshintsha, ukutshintsha, ukuzoba, kunye nokuthambisa.

Inkqubo yokuncedisa: Inkqubo yokujonga kwangaphambili, njengokucinezela umhlathi, ukucinezela umda we-Ingot yentsimbi, ukusika igxalaba, njl.

Inkqubo yokuGqibela: Inkqubo yokunciphisa isiphene somphezulu wokuxolelwa, njengokususa ukungalingani kunye nokucutha umphezulu wokuqinisa.

Inzuzo:

(1) Ukuqulunqa bhetyebhetye kukhulu, kungavelisa iziqwenga ezincinci ezingaphantsi kwe-100kg. Kwaye inokuvelisa iziqwenga ezinzima ukuya kwi-300t.

(2) Izixhobo ezisetyenzisiweyo zizixhobo ezilula ezilula.

. Ke ngoko, itoni yezixhobo zefomati ezifunekayo ukuba inyanzele ukuba i-gorcy efanayo incinci kakhulu kunoko inyanzelekile.

(4) Iimfuneko eziphantsi ngokuchanekileyo kwezixhobo.

(5) Umjikelo wemveliso mfutshane.

Izinto ezingalunganga:

(1) Ukusebenza kakuhle kwemveliso kuphantsi kakhulu kuneyo yokufa.

.

(3) Abasebenzi banengqongqongqongqo kwaye bafuna amanqanaba obuchwephesha obuphezulu.

(4) Akulula ukufezekisa usetyenziso kunye nokuzenzekelayo.

2. Ukufa

Ukufa ukrokrela kubhekisa kwindlela yokukhangela apho ujongiswayo afunyanwa ngokwenza amathuba ngokufa kwizixhobo ezikhethekileyo zokufa. Ukuxelwa okuvezwe ngale ndlela kukuchaneka ngobukhulu, ezincinci kwizibonelelo zomatshini, kunzima kwisakhiwo, kwaye ziphezulu kwimveliso.

Ihlelwe ngokwezixhobo ezisetyenzisiweyo: Dila kwi-hammer, ifa kwi-crank messing, ifa kwi-Fied kumatshini wokuthambisa, yifa kuMatshini weFlatch, njl.

Izibonelelo:

(1) Ukusebenza kakuhle kwemveliso ephezulu. Ngexesha lokufa, ukungcungcuthekiswa kwesinyithi kwenziwa kwi-cevity yokufa, ngoko ke kwafunyanwa imilo oyifunayo ngokukhawuleza.

(2) Ukuxolelwa ngezinto ezintsonkothileyo kunokwenziwa.

.

.

(5) Gcina izixhobo zentsimbi kwaye unciphise umthwalo wokusika.

(6) Ngaphantsi kwemeko yeebatch ezaneleyo, iindleko zenxalenye zinokuncitshiswa.

Izinto ezingalunganga:

.

.

.

I-3. Ukuqengqeleka

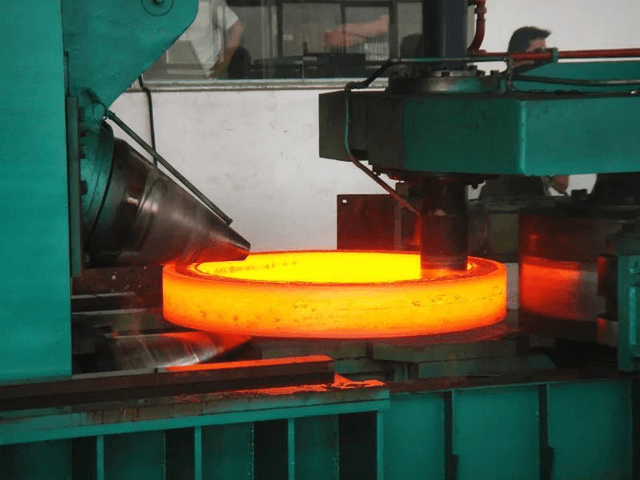

Ukuqengqeleka kwi-Commang kubhekisa kwinkqubo yokufowuna apho kufakwe khona isibini se-fan-fan ejikeleze i-factor factor i-billet ukufumana i-billet okanye i-billet.

Ukuqengqeleka i-Forformation yingxaki enobunzima emithathu. Uninzi lwezinto eziphathekayo ezihamba ngaphaya kwendlela ubude ukonyusa ubude beBillet, kunye nenxalenye encinci yezinto ezihamba-hamba zihamba kamva ukwandisa ububanzi beBillet. Ngexesha lenkqubo yokunyanzelwa, indawo enqamlezileyo yecandelo le-billet incipha ngokuqhubekayo. Inkqubo yeforati isebenzisa umgaqo-nkqubo wokuqulunqa ukwenziwa ngokuthe ngcembe ukuba ichaphazele.

Ukuqengqeleka kulungele iinkqubo zokulahleka njengokupheka kwe-shafts, ukuqengqeleka, kunye nokusasaza izinto ngobude. Ukuqengqeleka kunokusetyenziselwa ukuvelisa iintonga zokudibanisa, i-twist ye-bill, wills, iindlela, ii-hoes, amabala e-turbine, njl.

Xa kuthelekiswa nokukrwada kwesiqhelo, ukrola kuneengenelo zolwakhiwo lwezixhobo ezilula, ukuvelisa ezizinzileyo, ukuveliswa okuphantsi, ingxolo, ukulungelelaniswa kwempumelelo kwemveliso.

I-4. ITire ifa

I-TARE DIF inyanzela indlela yokukhangela ekhathalelayo eyamkela indlela yokufakelwa simahla ukwenza into engekhoyo, kwaye emva koko uyisebenzise eTire. Yindlela yokuqinisa phakathi kokukroba kwasimahla kunye nokufa. Isetyenziswe ngokubanzi kumashishini amancinci naphakathi anezixhobo zokuzifa ezinqabileyo kwaye uninzi lwayo luqokelela izando zasimahla.

Zininzi iindidi zezibumba ze-tire ezisetyenziswayo kwi-tire yokutsala, kwaye ezisetyenziswayo ezisetyenziswayo kwimveliso ziluhlobo, i-buckle mold, iseti ye-Buck, i-Clample.

I-cylinder evaliweyo isetyenziselwa kakhulu ukunyanzelwa kokuxolela ngokujikelezayo. Umzekelo, iigiya kunye nabaphathi kwiziphelo zombini ngamanye amaxesha zisetyenziselwa ukufuna ukuxolela ngokungekho ngxolo. I-cylindr evaliweyo inyanzela i-flash-simahla.

Kwisitiya sendle elixolelayo ngeemilo ezintsonkothileyo, kuyimfuneko ukongeza iziqingatha ezibini zesiqingatha (oko kukuthi, yongeza umphezulu wesahlulo) kwi-cylinder ye-cylinder ye-cylinder edibeneyo. Kwaye okungekho ngxaki kusekwe kwi-cavity eqokelelwe kwisiqingatha sesibini.

Ifilimu yokudibanisa idla ngokudityaniswa ngamacandelo amabini, indawo ephezulu nangaphantsi. Ukwenzela ukutshatisa i-OPT kunye nesezantsi i-DEE DEE kwaye inqande ukuxolela okuvela ekutshintsheni, izithuba zesikhokelo kunye nezikhonkwane zezikhokelo zihlala zisetyenziselwa ukubeka. Ukudalwa kwe-chipping kusetyenziswa kakhulu ukuvelisa uxolelo olungaguqukiyo oluneemilo ezintsonkothileyo, njengokudibanisa iintonga, ukuxolelaniswa kweentonga, ukuxolelanisa, njl.

Xa kuthelekiswa nokunyanzelwa kwasimahla, i-cire yokufa inyanzela ukuba lelutyebi inezibonelelo zilandelayo:

.

.

. Kuba imilo yokutsala ilawulwa yi-DEAVIT, le ingenanto yenziwa ngokukhawuleza. Kwaye imveliso i-1 ukuya kwezi-5 ngaphezulu kunelo yokuzibandakanya ngokukhululekileyo.

(4) Kukho iibhloko ezimbalwa ezisele, ke isibonelelo soomatshini sincinci. Oku kungasindisanga kuphela kwezinto zentsimbi kodwa kunciphise iiyure zabantu.

Izinto ezingalunganga:

.

(2) Kuphela nje okuxolelekileyo okuxolelwayo;

(3) Ubomi benkonzo ye-cire bubuld buphantsi;

.

.

UZhengxi uqondiswe kakuhleUKUFAKWA KOMFAZWE ECINA, ukubonelela ngeendlela ezahlukeneyo zomatshini wokushicilela, kubandakanya oomatshini bokubhabha basimahla, bafa oomatshini bokukhangela,oomatshini bokutsala, oomatshini bokukhwelaUomatshini bokufudumeza, njl njl. Ukuba unazo ezinye iimfuno, nceda unxibelelane nathi.

I-Post Ixesha: Jun-30 ukuya ku-2023