I-Blackmiting yindlela yakudala neyeyona nto ibalulekileyo yensimbi yokuhamba ngesondo ibuyele kwi-2000 BC. Isebenza ngokufudumeza isinyithi singenanto kwiqondo lokushisa elithile kwaye sisebenzise uxinzelelo ukuyilwa kwimo efunekayo. Yindlela eqhelekileyo yokwenza amandla aphezulu, iinxalenye eziphezulu zokwenza. Kwinkqubo yokukrokrela, zimbini iindlela eziqhelekileyo, ezizezisi zikhululekile kwaye zife. Eli nqaku liza kuphonononga umahluko, izibonelelo kunye nezinto ezingalunganga, kunye nokusetyenziswa kwezi ndlela zimbini.

Ukuthoba ngokukhululekileyo

Ukuzibandakanya ngokukhululekileyo, okwabizwa ngokuba yi-hammer ye-rummer okanye inkqubo yokuthintela yasimahla, yindlela yokutsala intsimbi ngaphandle kokubumba. Kwinkqubo yokufowuna yasimahla, i-forting ingenanto (ihlala ibhloko yentsimbi okanye i-rod) ishushu kubushushu apho iba yiplastiki kwaye emva koko ifakwe kwi-racker okanye i-cinezela. Le nkqubo ixhomekeke kwizakhono zabasebenzi abasebenzayo, ezifuna ukulawula ubume kunye nobungakanani ngokujonga kunye nokusebenzisa inkqubo yefomati.

IZIBONELELO ZOKUGQIBELA ZOKUGQIBELA:

I-1. Ukuguquguquka: Ukuzibandakanya ngokukhululekileyo kulungele imisebenzi esebenzayo yeemilo ezahlukeneyo kunye nobungakanani kuba akukho mfuneko yokuba wenze ibumba.

2. Ukugcina izinto ezibonakalayo: Kuba akukho sifo, akukho zixhobo ezongezelelweyo ezifunekayo ukwenza ubumba, onokunciphisa inkunkuma.

I-3. Ifanelekile kwimveliso ye-batch encinci: Ukuzibandakanya ngokukhululekileyo kulungele ukuveliswa kwe-batch encinci kuba ukuveliswa kwesininzi kwezinto ezingafuneki.

Izinto ezingalunganga zokunyanzelwa simahla:

1. Ukuxhomekeka kwizakhono zabasebenzi: Umgangatho wokubhabha simahla kuxhomekeke kubuchule babasebenzi kunye namava, ke iimfuno zabasebenzi ziphezulu.

2. Isantya semveliso esicothayo: xa kuthelekiswa nokukrwada, isantya semveliso yokuzibandakanya simahla kuyacotha.

I-3. Ubume kunye nolawulo lobungakanani bunzima: Ngaphandle koncedo lwezinto zokubumba, ubume kunye nobungakanani bokulawula ngokukhululekileyo kunzima kwaye kufuna ukulungiswa okungalandelayo.

Izicelo zokuSebenza simahla:

Ukunyanzelwa simahla kwezi ndawo zilandelayo:

1. Ukuvelisa Iindidi ezahlukeneyo zeenxalenye zentsimbi ezinjengokutyumba, iinxalenye zesando, kunye neenkcazo.

2. Veza amandla aphezulu kunye neenxalenye eziphezulu zoomatshini ezifana ne-crankshafts, ezidibanisa iintonga kunye nebheringi.

3. Ukuphosa izinto eziphambili zezixhobo zobunjineli nezixhobo zobunjineli.

Yifa

Ukufa ukuba ukutyhobo yinkqubo esebenzisa i-faies yokufumana i-certi. Kule nkqubo, intsimbi engenanto ibekwe kubumba olwenziwe ngokukodwa kwaye emva koko yakhiwe kwimo efunwayo ngoxinzelelo. I-FOLDS ingaba qabane okanye ilungu elininzi, kuxhomekeka kubunzima benxalenye.

Izibonelelo zokufa zinyanzeliswa:

1. Ukuchaneka okuphezulu: Ukunyanzelwa ukuba unike ubume obuchanekileyo kunye nolawulo lobungakanani, ukunciphisa isidingo sokulungisa okulandelayo.

2. Iziphumo eziphezulu: Oko ubumba bungasetyenziswa amaxesha amaninzi, ukubumba kukolingeka kufanelekile kwimveliso yobuninzi kwaye kuphuculwe ukusebenza kwemveliso.

3. Ukungqinelana okuhle: Ukufa kukaFayile kunokuqinisekisa ukungqinelana kwenxalenye nganye kunye nokunciphisa ukwahluka.

Izinto ezingalunganga zokufa:

I-1. Iindleko eziphezulu zemveliso: Ixabiso lokwenza i-rolds entsonkothileyo liphezulu, ngakumbi kwimveliso ye-batch encinci, engabizi ndleko.

2. Ayilunganga imilo ekhethekileyo: kuba macala anzima okanye abuhlungu okanye ongekho mthethweni, ukubumba kwexabiso eliphezulu kusenokufuneka kwenziwe.

3. Ayilunganga kwiqondo lokunyathela eliphantsi: Ukufa lihlala lifuna ubushushu obuphezulu kwaye abusebenzi ngamacandelo afuna ukunyanzelwa kobushushu obuphantsi.

Ukusetyenziswa kokufa:

Ukufa ukuba usetyenziswe ngokubanzi kula macandelo alandelayo:

1. Ukuveliswa kweenxalenye ze-Automotive ezinjengee-injini ye-injini, iidiski ze-brake, kunye neevibs zevili.

I-2. Ukuvelisa iinxalenye eziphambili zecandelo le-aerospace, ezinjengeenqwelo moya, iinxalenye ze-injini, kunye nezinto zolawulo lwebhayisensi.

3. Veza iindawo ezinezobunjineli ezichanekileyo ezinjengeebheringi, iigiya kunye neeracks.

Ngokubanzi, ukutyhola ngokukhululekileyo nokufa kuya kutonwabela ngamnye izibonelelo kunye nokusikelwa kwaye kufanelekile kwiimfuno ezahlukeneyo zemveliso. Ukukhetha indlela efanelekileyo yokunyanzela kuxhomekeka kubunzima benxalenye, ivolumu yemveliso, kunye nokuchaneka okufunekayo. Kwizicelo ezisebenzayo, ezi zinto zihlala zifuna ukunyanzeliswa ukufumanisa inkqubo efanelekileyo yokulinganisa. Uphuhliso oluqhubekayo kunye nokuphuculwa kweenkqubo zokwenza iifomaka kuya kuqhubeka nokuqhuba iindawo zesicelo zazo zombini iindlela.

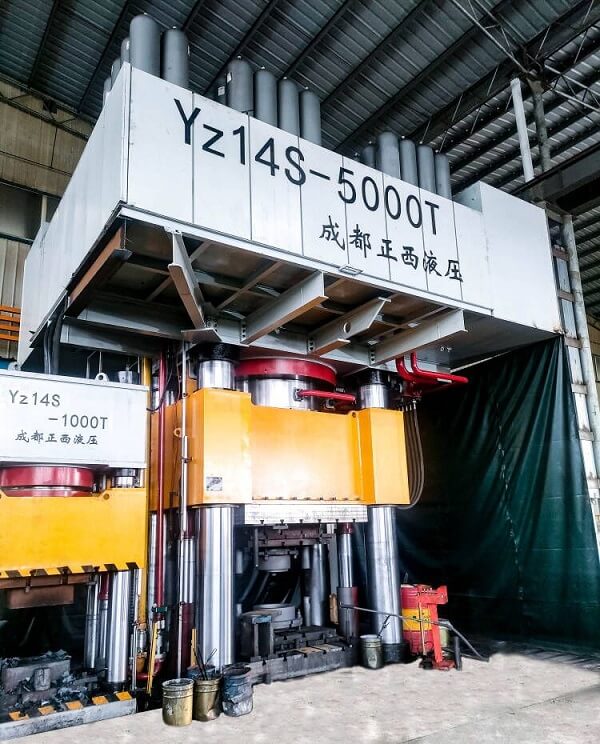

Zhengxi yingcaliUmzi-mveliso wokushicilela kwi-China, ukubonelela ngomgangatho ophezuluI-forpes yoomatshinikwaye ufe oomatshini bokuzila. Ukongeza, oomatshini bokushicilela be-hydraulic banokwenziwa kwaye baveliswa ngokweemfuno zabathengi. Ukuba unazo naziphi na iimfuno, nceda unxibelelane nathi.

IXESHA LOKUQALA: UPE-09-202333