Ngophuhliso oluqhubekayo lwezixhobo zokuhlanganisa, ukongeza kwiglasi ye-fiber-yongeza iplastiki, i-carbon fiber-eqinile iplasitiki, i-boron fiber-ivele. I-carbon fiber yomeleziwe i-Polymer Popositi (CFRP) ilula kwaye isetyenziswa izixhobo eziqingqiweyo ezisetyenziselwa ukwenza iimveliso ezininzi esizisebenzisayo kubomi bethu bemihla ngemihla. Ligama elisetyenziselwa ukuchaza izixhobo zokudibanisa izinto eziqingqiweyo ezisebenzisa i-carbon fibers njengeyona nto iphambili yolwakhiwo.

Itheyibhile yomxholo:

I-1. I-Carbon Fiber yomele ubume bePolymer

I-2. Indlela yokubumba ye-carbon fiber eqiniswe ngeplastiki

I-3. Iipropathi ze-carbon fiber ifihliwe i-polymer

4. Izibonelelo zeCFRP

I-5. Ukungancedi yi-CFRP

I-6. I-Carbon Fiber isetyenziselwe iplastiki esetyenziswayo

I-carbon fiber yoqinile kwi-Polymer

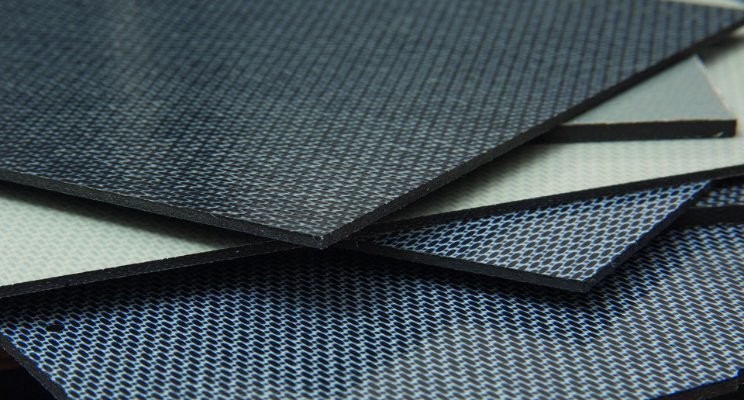

I-Carbon Fiber eqingqiweyo yeplastiki yinto eyenziwayo ngokulungiselela izixhobo ze-carbon fiber kwindawo ethile kwaye zisebenzisa izixhobo zepolymer ezinesidima. Ububanzi befibebe yekharbon briker kakhulu, malunga nemicrons eziyi-7, kodwa amandla ayo aphakamile kakhulu.

Esona siseko sibalulekileyo esibonakalayo se-carbon fiber se-fiber eqinisa izinto ezihlanganisiweyo ze-carbon filar. Izinto ezisisiseko ze-carbon ye-carbon yiPolyacyrlornfornnikarimitrley (Pan), iRayon, okanye iPetroleum. Iifilimenti zekhabhoni zenziwa kwi-carbon firrics zefayili ngemichiza kunye neendlela zoomatshini kwiinxalenye ze-carbon fiber.

I-polymer ebophayo ihlala ihamba i-thermoset resin efana ne-epoxy. Ezinye ii-thermosets okanye i-thermoplastic polymers ngamanye amaxesha zisetyenziswa, njenge-polyvinyl acetate okanye inylon. Ukongeza kwimicu yekharbon, izihlunu zinokuqulatha i-Aramid Q, i-ultra-goone molethylene, ialuminiyam, okanye iintsinga zeglasi. Ipropathi yemveliso ye-carbon ye-fiber yokugqibela inokuchaphazeleka luhlobo lweezongezo ezingeniswe kwi-bondix ye-bondix.

Indlela yokubumba ye-carbon fiber eqinisiweyo

Iimveliso ze-carbon fiber zahlukile ngenxa yeenkqubo ezahlukeneyo. Zininzi iindlela zokwakha i-carbon fiber eqinisa i-polymer.

I-1. Indlela yokubeka ngesandla

Yahlulahlulwe yaba yindlela eyomileyo (ivenkile elungisiweyo) kunye nendlela emanzi (ifayibha yefayibha (i-wible ye-resic ihlawulwe). Ukulala ngesandla kukwasetyenziselwa ukulungiselela i-Pregregs ukuze isetyenziswe kwiinkqubo zokubumba zesibini ezifana nokubumba. Le ndlela kulapho amaphepha e-carbon fiber ilaphu inyibilikisiwe kwi-mold ukwenza imveliso yokugqibela. Amandla kunye nezixhobo zokuqina kwezinto eziphumlweni zilungiselelwe ngokukhetha ulungelelwaniso kwaye uluka ngeentsinga zelaphu. Ubumba buzaliswe yi-EPOXY kwaye iphiliswe ngobushushu okanye umoya. Le ndlela yokuvelisa ihlala isetyenziselwa iindawo ezingagxilanga, ezinjengeenjini.

I-2. Indlela yokwakha i-vacuum

Ukufumana i-Perpremed Perty, kuyimfuneko ukufaka uxinzelelo ngenkqubo ethile ukuyenza kufutshane nokubumba kunye nokunyanga kwaye uyilo kwaye uyilondoloze phantsi kobushushu obuthile kunye noxinzelelo. Indlela yengxowa ye-vacuum isebenzisa impompo yevacuum yokuphumeza ngaphakathi kwingxowa yengxowa ukuze ingcinezelo engalunganga phakathi kwengxowa kunye nokubumba kudala uxinzelelo ukuze imbambano isondele kakhulu ekubumbeni.

Kwisiseko sendlela yengxowa ye-vacuum beg, i-vacuum yengxowa yengxowa yengxowa yafumaneka kamva. I-Autoclaves ibonelela ngoxinzelelo oluphezulu kunye nobushushu inxenye (endaweni yonyango lwendalo) kunendlela yengxowa ye-vacuum kuphela. Inxalenye enjalo inesakhiwo esingakumbi, umgangatho ongcono womhlaba, unokuphelisa ngokufanelekileyo amaqamza omoya (amaqamza aya kuchaphazela kakhulu amandla enxenye), kwaye umgangatho wonke uphakamileyo. Ngapha koko, inkqubo yengxowa ye-vacuum ifana ne-filimu yefilimu yefilimu. Ukuphelisa iibbhu ze-air ngumsebenzi ophambili.

I-3. Indlela yokuBumba

Ukubumbayindlela yokubumba elungele ukuveliswa kobuninzi kunye nemveliso yobuninzi. Izibungu zihlala zenziwa ngamacandelo aphezulu aphezulu, esikubiza ngokuba sisifo sobunjiweyo kunye nebhinqa. Inkqubo yokubumba kukubeka i-mat esenziwe nge-Predgs kwi-Counter yensimbi, kwaye phantsi kwesenzo sobushushu obuthile kunye noxinzelelo, ukugcwaliswa komzimba kwaye ugcwalise i-mold cavity, kwaye ugcwalise kwaye ucalu ukuze ufumane iimveliso. Nangona kunjalo, le ndlela inexabiso eliphezulu kunangaphambili, kuba isisu sifuna ukubakho okuphezulu kwe-CNC.

I-4. Ukubumba umoya

Kwiinxalenye ezinemilo entsonkothileyo okanye kubume bomzimba wenguquko, i-filamer fener enokusetyenziselwa ukwenza isabelo ngokutsala i-filing okanye i-core. Emva komoya unyango ngokupheleleyo kwaye ususe i-mandrel. Umzekelo, iingalo ezidibeneyo ze-tubula ezisetyenziswa kwiinkqubo zokumiswa zinokwenziwa zisebenzisa le ndlela.

I-5. I-resin Transfer

I-Retin Transfering (i-RTM) yindlela edumileyo edumileyo. Amanyathelo ayo asisiseko:

1. Beka i-carbon yefibre ye-carbon fir kwi-moldm kwaye ivale ibumba.

2. Ukutsala i-theriffti ye-tinftin kuyo, kunqande izinto zokuqinisekisa ukuqina, kunye nokunyanga.

Iipropathi ze-carbon fiber yomeleleyo

(1) Amandla aphezulu kunye nexesha elifanelekileyo.

Amandla athile (oko kukuthi, umyinge wamandla e-tensle kuxinzelelo) ye-carbon fiber ngamaxesha ama-6 akwintsimbi yamaxesha e-aluminium. Imodyuli ethile (oko kukuthi, umyinge wemodyuli yolutsha ukuya kuxinzelelo, ongumqondiso wokuqina kwento) ingaphezulu kwamaxesha ama-3 entsimbi okanye i-aluminium.

Ngamandla aphezulu, inokuthwala umthwalo omkhulu wokusebenza. Uxinzelelo lwayo oluninzi lokusebenza lunokufikelela kuma-350 kg / cm2. Ukongeza, kuyaphazamiseka ngakumbi kwaye kuyanceda kune-F-4 kunye ne-braid yayo.

(2) Ukungaxhathisi kakuhle kwaye unxibe ukunganyangeki.

Ukungakhathali kwayo okudilayo kungaphezulu kakhulu kunelo ye-epoxy ren kwaye iphakame kuneso sixhobo sentsimbi. I-graphite fibers iyaziqhelanisa kwaye isebenze kancinci ukuxabana. Inani lokunxiba ngamaxesha ama-5 ukuya kweli-7 elincinci elincinci kunezo kwiimveliso zika-Asbestos zika-Asbestos okanye ii-FAID ze-F-4.

(3) Ukusebenza okuhle kunye nokumelana nobushushu.

I-carbon fiber eqinisa iplasitiki iyonwabisayo, kwaye ubushushu obuveliswe ziimbambano zichithwe ngokulula. I-Interrior akukho lula ukulala kwaye igcine ubushushu kwaye inokusetyenziswa njengezinto ezinamandla zokutywina. Emoyeni, inokusebenza ngokuthobekileyo kuluhlu lwamaqondo obushushu lwe-320 ~ 350 ° C. Ngokuncitshiswa komxholo wesinyithi alkali kwi-Carbon Fiber, amaqondo obushushu enkonzo anokwanda ngakumbi. Kwirhasi ye-intert, ubushushu bayo obuhlekisayo bunokufikelela malunga nowama-2000 ° C, kwaye inokumelana neenguqu ezibukhali nobushushu.

(4) Ukunganyangeki kwentshukumo elungileyo.

Akulula ukuphinda okanye i-flutter, kwaye ikwayinto ebalaseleyo yokuphucwithelwa kwendalo kunye nokuncitshiswa kwengxolo.

Izibonelelo zeCFRP

1. Ubunzima bokukhanya

I-fiber ye-fiber ye-fiber ye-fiber eqinileyo isebenzisa i-fibers yeglasi eqhubekayo kunye neentsinga ezingama-70 Ingqumbo ye-CFRP ene-70% ye-fiber ubunzima obuqhelekileyo inobunzima beekhilogramu eziyi-0,055 kwi-intshi nganye ye-cubic.

2. Amandla aphezulu

Nangona i-fiber ye-carbon ye-farbon yaqinisa i-Polymers iphosakele, iindidi ze-CFRP zinamandla aphezulu kunye nokuqina okuphezulu kweyunithi kuneglasi yeglasi. Xa kuthelekiswa nezinto zentsimbi, olu ncedo lucacile ngakumbi.

Izinto ezingalunganga zeCFRP

I-1. Iindleko eziphezulu

Ixabiso lemveliso le-carbon firbon firchentware eqinileyo iplastiki ithintelo. Amaxabiso e-carbon fiber anokutshintsha kakhulu kuxhomekeka kwiimeko zangoku zentengiso (ubonelelo kunye nemfuno), uhlobo lwe-carbon fiber (i-aerospace v. Ibanga le-fiber bundle. Kwisiseko sepaund-ye-pound-pund-fiber i-farbon ye-carbon inokuba ngama-5 ukuya kwangama-25 kuyabiza kakhulu kune-fiber yeglasi. Lo mahluko mkhulu nangakumbi xa uthelekisa intsimbi kwi-CFRP.

2. Ukuqhutywa

Esi sisibonelelo kunye nokungancedi kakuhle kwizinto ezithile ze-carbon fiber. Kuxhomekeka kwisicelo. I-carbon fibers iqhuba kakhulu kwaye iglasi yeglasi iyabhabha. Iimveliso ezininzi zisebenzisa i-fiberglass endaweni ye-carbon fiber okanye intsimbi kuba zifuna ukufuduswa okungqongqo. Kwimveliso yezixhobo, iimveliso ezininzi zifuna ukusetyenziswa kweentsinga zeglasi.

I-carbon fiber firliclectication isebenzisa

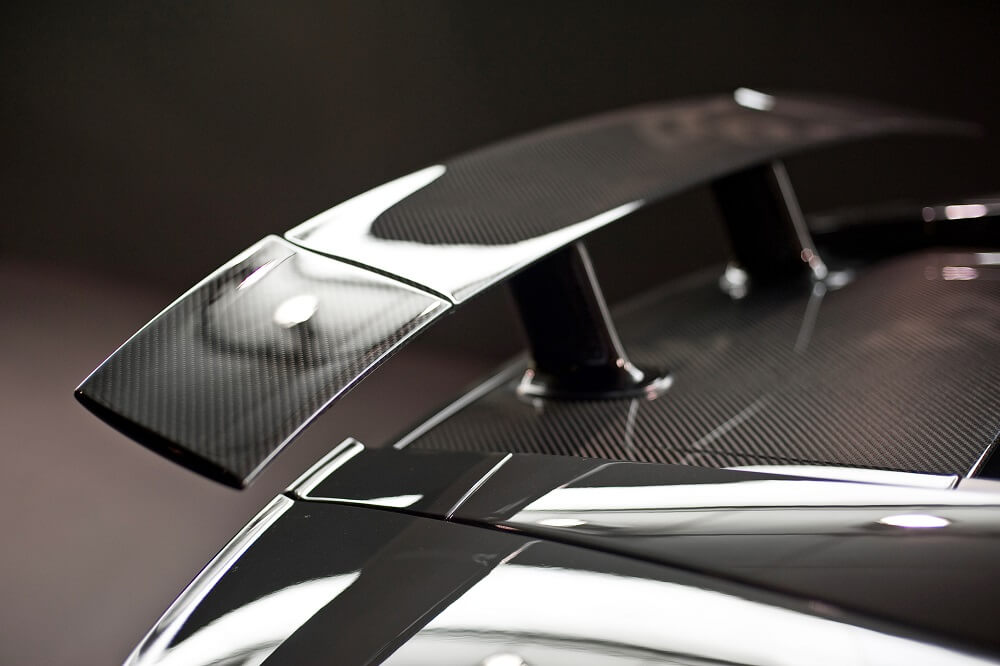

Izicelo ze-carbon fiber firmer of Polymer zibanzi ebomini, ukusuka kumacandelo oomatshini ukuya kwizasemkhosini.

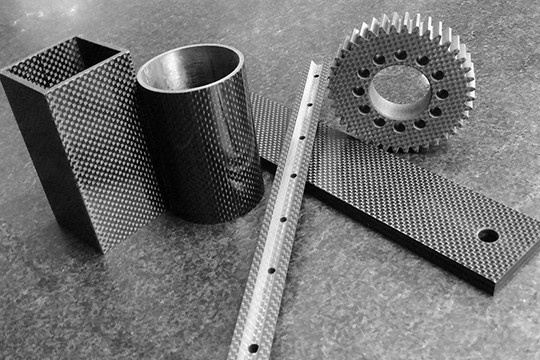

(1)njengokupakisha

I-carbon fiber yoqingqiweyo ye-ptfese ingenziwa ukuba ichaphazele, inxibe-ukudinwa, kunye ne-rings encomekayo. Xa isetyenziselwa ukutywinwa komhlaba, ubomi benkonzo bude, ngaphezulu kwamaxesha amashumi ali-10 ubude kuneso se-oyile jikelele ye-Asbestos. Ingayigcina intsebenzo yokutywina phantsi kotshintsho lomthwalo kunye nokuphola ngokukhawuleza kunye nokufudumeza ngokukhawuleza. Kwaye ekubeni izinto ezibonakalayo zingaqulathanga izinto ezibonisa ukuba, akukho phunga lokungazicikisi.

(2)njengamalungu okugaya

Isebenzisa iipropathi zayo zokuzithoba, inokusetyenziswa njengebherings, iigiya, kunye namakhonkco episton ngeenjongo ezizodwa. Iibhetri ezinamafutha ahamba ngeoyile yezixhobo zokuhamba kweenqwelo moya kunye nee-tee zetayini, i-oyile engaphakathi ye-ioyile yokuhambisa i-piston yombane (ukuthintela iingcali ze-piston ezibangelwa kukutya okanye amashishini okutya ngeoyile ngokusebenzisa iimpawu ezingenabungozi.

(3) Njengoko izinto zolwakhiwo ze-aerospace, inqwelo moya, kunye nemijukujelwa. Kwaqala ukusetyenziswa kwimveliso yeenqwelomoya ukunciphisa ubunzima bendiza kunye nokuphucula ukusebenza kwenqwelomoya. Ikwasetyenziswa kwikhemikhali, ipetroleum, amandla ombane, oomatshini, kunye namanye amashishini njengeTywina elijikelezayo okanye lokufumana itywina okanye izixhobo ezahlukeneyo zetywina.

Zhengxi yingcaliI-Hydraulic Prefic Prefic e China, ukubonelela nge-quliatycoca cinezela i-hydraulicukwenza iimveliso ze-CFRP.

Ixesha lokuposa: I-25-2023