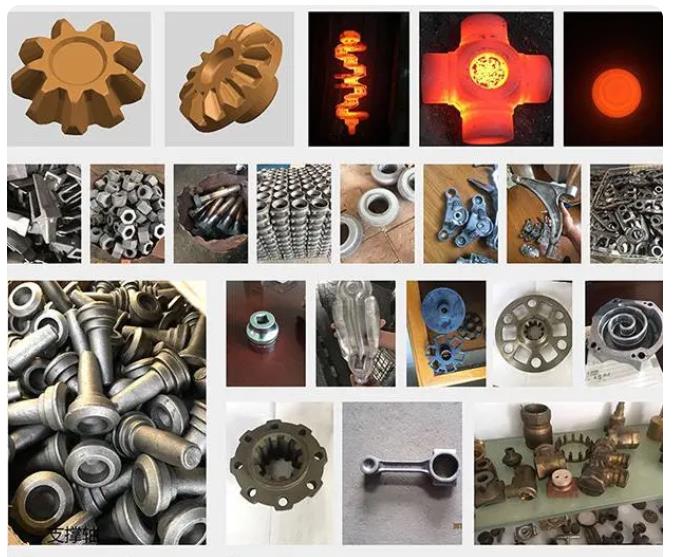

Ukunyanzelwa ligama elidityanelweyo lokukrokrela kunye nokubetha. Yindlela yokulungisa esebenzisa isando, i-anvil, kunye ne-punch yamatshini wokukrola okanye ukubumba ukuze enze uxinzelelo kwinto engenanto yokwenza iinxalenye zezahlulo zeplastiki kunye nesayizi.

Yintoni

Ngexesha lenkqubo yokunyanzela, yonke ingenanto ingenanto ingenayo ishedyuli ebalulekileyo yeplastiki kunye nexabiso elikhulu lokuhamba kweplastiki. Kwinkqubo yentsimbi, le nto ingenanto yenziwa ikakhulu ngokutshintsha indawo yendawo yendawo nganye, kwaye akukho ukuhamba ngeplastiki ngaphezulu komgama omkhulu ngaphakathi. Ukutopha kusetyenziswa ikakhulu ukwenza iinxalenye zentsimbi. Ingasetyenziselwa ukuqhubela phambili izinyithi ezithile, ezinje ngeplasitiki yobunjineli, iirabha, iingubo ze-ceramic, izitena, kunye nokusekwa kwezinto ezihlanganisiweyo.

Ukuqengqeleka, ukuzoba, njl njl. Nangona kunjalo, ukuqunjelwa kusetyenziswa ikakhulu ukuvelisa iinxalenye zentsimbi, ngelixa uqengqeleka kunye nokuzoba kusetyenziswa ikakhulu ukuvelisa izixhobo zentsimbi jikelele ezinje ngeepleyiti, imitya, iiprofayili, kunye neeprofayili.

Ukwahlulahlula

Ukuqunjelwa kuhlelwe ngokucokisekileyo ngokwendlela yokwakha kunye nobushushu bokusebenza. Ngokwendlela yokuseka, ukutyhobozela kunokwahlulwa kuba ziindidi ezimbini: ukutyhobozela kunye nokubetha. Ngokutsho kobushushu bokusebenza, ukutyhobozela kunokwahlulahlulwa ukuba kushushu, kubanda kakhulu, ukubanda, ukufudumala, kunye ne-isothermal ekrwada, njl.

1. Ishushu

Ukunyanzelwa okukhoyo kuyanyanzelwa ngaphezulu kweqondo lobushushu be-recrystalling yentsimbi. Ukonyusa amaqondo obushushu anokuphucula iprintation yentsimbi, nto leyo eyingenelo ekuphuculeni umgangatho we-onrinsiac kunye nokwenza kube lula ukuqhekeza. Amaqondo obushushu aphezulu anokunciphisa nokunganyangeki kwesinyithi kwaye kunciphise i-tonnage yento efunekayoUomatshini bokukrazula. Nangona kunjalo, zininzi iinkqubo ezishushu ezishushu, ukuchaneka kwenkqubo enguMsebenzini kulihlwempu, kwaye umphezulu awugudileyo. Kwaye ukuxolela kuxhaphake ekucingeni Xa umsebenzi ongumsebenzi omkhulu kwaye ubukhulu, i-round inamandla aphezulu kunye neplasitiki (njengokugoba iipleyiti eziphezulu, umzobo we-rods ye-carbon, njl. Njl.), Kwaye kusetyenziswa i-njalo.

Ngokubanzi isetyenziselwa amaqondo obushushu ashushu ashushu: I-Carbon Steel 800 ~ 1250 ℃; Isakhiwo sesakhiwo sesakhiwo 850 ~ 1150 ℃; Isantya esiphezulu sentsimbi 900 ~ 1100 ℃; I-Aluminum exhaphakileyo ye-Aluminum i-Alloum 380 ~ ℃; Alloty 850 ~ 1000 ℃; I-brass 700 ~ 900 ℃.

I-2. Ukubanda kakhulu

Ukuqunjelwa kubanda kukufowuna okwenziwa ngezantsi kweqondo lobushushu besinyithi. Ngokubanzi, ukutywina okubandayo kubhekisele ekuthatheni ubushushu begumbi.

Izinto zomsebenzi ezenziwa ngokubanda kakhulu kubushushu begumbi zinobume obuphezulu kunye nokuchaneka kwendawo, indawo egudileyo, iphucule impumelelo, kwaye ilungele ukuveliswa ngokuzenzekelayo. Iinxalenye ezininzi ezibandayo kwaye ezibandayo zinokusetyenziswa ngokuthe ngqo njengeenxalenye okanye iimveliso ngaphandle kwesidingo somatshini. Nangona kunjalo, ngexesha lokubanda kubandayo, ngenxa yeplasitiki yentsimbi, ukuqhekeka kulula ukuba kwenzeke ngexesha lokusebenza kunye nokuchasana nokunganyangeki kuyinto enkulu yokufuna oomatshini abaninzi.

I-3. Ukunyanzelwa

Ukutopha kubushushu obuphakamileyo kunobushushu obuqhelekileyo kodwa ungagqithiseli kubushushu be-recrystallic kubizwa ngokuba yi-Frust. Isinyithi sikhethiwe, kwaye ubushushu obufudumeleyo bungaphantsi kakhulu kunendlela eshushu. Ukunyanzelwa okufudumeleyo kuyachaneka okuphezulu, umphezulu otyhafileyo, kunye nokungakhathali kokufezekisa.

I-4. I-isothermal inyanzela

I-isothermal inyanzelisa iqondo lobushushu elingenanto rhoqo ngalo lonke inkqubo yokuseka. I-isothermal ye-isothel kukwenza ipristraty epheleleyo yeentsimbi ezithile kwiqondo lobushushu olufanayo okanye ukufumana izakhiwo ezithile kunye neepropathi. I-isothermal ye-isothel ifuna ukugcina ubumba kunye nempahla embi kwiqondo lokushisa rhoqo, elifuna iindleko eziphezulu kwaye isetyenziswa kuphela kwiinkqubo ezikhethekileyo zokuzonwabisa, ezinje ngemilinganiselo yexabiso.

Iimpawu zokwenza

Ukunyanzelwa kunokutshintsha isakhiwo sesinyithi kunye nokuphucula iipropathi zensimbi. Emva kokuba i-Iyot ishushu, ukukhululeka, iipores, imicro-rock, njl njl. Izihlobo zantlandlolo ziyaqhekeka, zenza ukuba i-Grains icoceke. Kwangelo xesha, i-carbide yoqobo ye-carbide kunye nokusasazwa okungalinganiyo kutshintshiwe. Yenza iyunifomu yesakhiwo, ukufumana ukuxolela ukuba incinci, iyunifomu, isohlwayo, ibe nentsebenzo elungileyo, kwaye isetyenziswa ngokukholekileyo. Emva kokutsala ubuqhetseba ngokungxama, isinyithi sinesakhiwo esinefutha. Emva kokuphela kwengxaki yokubanda, i-crystal yentsimbi iba ngumyalelo.

Ukunyanzelwa kukwenza ukuhamba kwentsimbi ukwenza i-fortional ukwenza umsebenzi osebenzayo wemo efunwayo. Umthamo wesinyithi awutshisi emva kokuhamba kweplastiki kwenzeka ngenxa yamandla angaphandle, kwaye intsimbi ihlala ihamba iye kwinxalenye kunye nokuchaswa okuncinci. Kwimveliso, ubume bendawo yokusebenza ihlala ilawulwa ngokwemithetho yokufezekisa izigqibo ezifana nokutyibilika, i-elongwation, ukwanda, kunye nomzobo onzulu.

Ubungakanani bomsebenzi wokusebenza owenziweyo buchanekile kwaye bulungele ukulungiselela ukuveliswa kobuninzi. Imilinganiselo yokwakhiwa kwezicelo ezinjengokukrokrela, ukupheliswa, kunye nesitampu zichanekile kwaye zizinzile. Ukunyanzelwa kwe-pieding godiys kunye nemigca yokuvelisa ngokuzenzekelayo kunokusetyenziselwa ukulungiselela ubunzima obukhethekileyo okanye ukuveliswa kwesininzi.

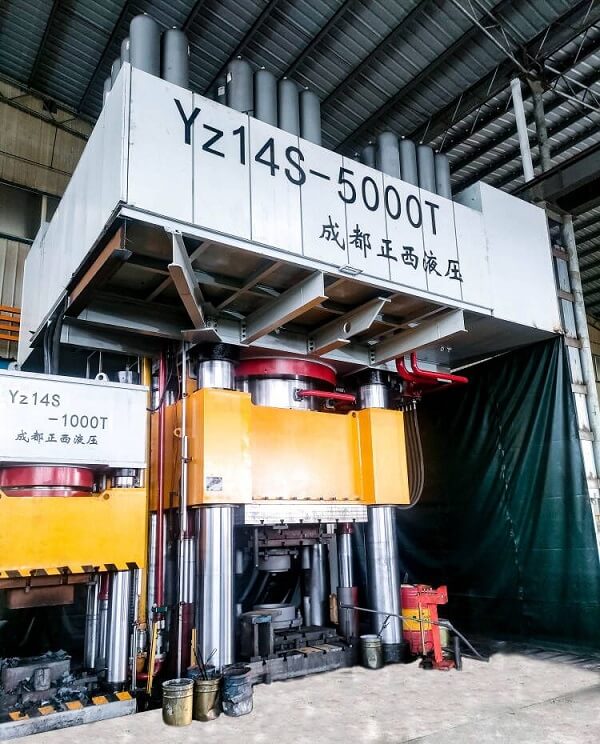

Ihlala isetyenziselwa oomatshini bokukrazula kubandakanya izando ezikrazulayo,Oomatshini bokushicilela be-hydraulic, oomatshini bokushicilela. I-hammer yesando inesantya esikhulu sefuthe, esiyingenelo ekuhambeni kweplastiki, kodwa iya kuvelisa nzondo. Umatshini wokushicilela we-hydraulic usebenzisa i-static biling, nto leyo eyingenelo ukuba inyanzelise intsimbi kwaye iphucule isakhiwo. Umsebenzi uzinzile, kodwa imveliso iphantsi. Umatshini wokushicilela unesitayile esisigxina kwaye kulula ukuphumelela umatshini kunye nokuzenzekelayo.

Umgangatho woPhuculo lweTekhnoloji

1) Ukuphucula umgangatho wezinto eziguqulweyo zenxalenye yezinto ezinxulumene noko, ikakhulu ukuphucula iipropathi zabo (amandla, ubuchule, amandla, amandla okudinwa, amandla okudinwa) kunye nokuthembeka.

Oku kufuna ukusetyenziswa okungcono kwethiyori yengcaciso yeplastiki. Faka isicelo sozixhobo kunye nomgangatho ongcono wentlukwano, onjenge-vacuum-ephathwe intsimbi kunye nentsimbi enyibilikisiweyo. Yenza imfumba yokufudumeza kwangaphambili kunye nokukrazula unyango lobushushu ngokuchanekileyo. I-Rigorous engqongqo kunye nebanzi engaqhelekanga yamalungu anempumelelo.

2) Kukwenza ngakumbi itekhnoloji yokuchaneka kunye nokuchaneka kwesitampu. Ukuqhubekeka okungapheliyo yeyona ndlela ibaluleke kakhulu kunye nolwalathiso lukamatshini lomatshini ukuphucula ukusetyenziswa kwezixhobo, ukuphucula ukuhlawulwa kwabasebenzi, kunye nokunciphisa ukusetyenziswa kwamandla. Ukuphuhliswa kwenkungu engekhoyo yokuyikhathaza i-fanks, kunye nobunzima obuphakathi, bunganyangeki, kunye neendlela zobomi obude, ziya kuba lula ukuba kusetyenziswe isitampu esandisiweyo sokuchaneka kunye nokuchaneka kwesitampu esifanelekileyo.

3) Ukuphuhliswa kwezixhobo zokungena kunye nokukrazula imigca yemveliso ngemveliso ephezulu kunye nokuzenzekelayo. Ngaphantsi kwemveliso ekhethekileyo, imveliso yabasebenzi iphuculwe kakhulu kwaye iindleko zokuhlawula zincitshisiwe.

4) Phuhlisa iinkqubo zokwenza ubuchwephesha obuguqukayo (ukusebenzisa itekhnoloji yeqela, ukutshintsha okukhawulezileyo kweqela, njl. Njl.). Oku kwenza ukuba imveliso eyahlukeneyo emininzi, i-batch encinci yokunyanzela ukuba isebenzise ukusebenza kakuhle kunye nezixhobo ze-rating ezizenzekelayo okanye imigca yemveliso. Yenza imveliso yayo kunye noqoqosho zikufutshane kwinqanaba lemveliso yobuninzi.

5) phuhlisa izixhobo ezitsha, ezinjengokunyanzeliswa kweendlela zokwenza izinto ze-powersgergy ze-powder. Ukuphuhliswa kwetekhnoloji efana nokwenza i-superplast, ukuFowuna kwamandla aphezulu, kunye nokwenza uxinzelelo lwangaphakathi.

IXESHA LOKUQALA: FEB-04-2024